Sandstone Patio

Sandstone Patio

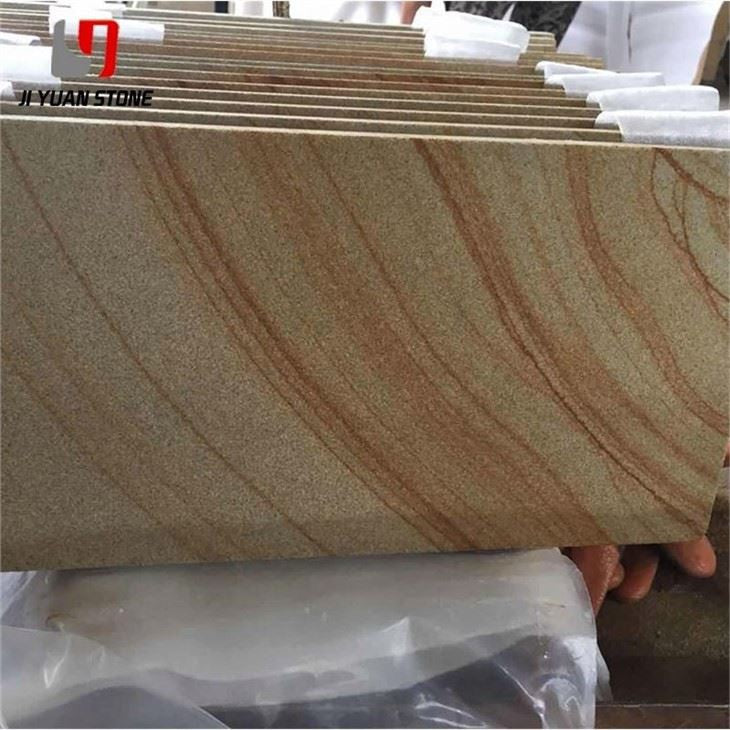

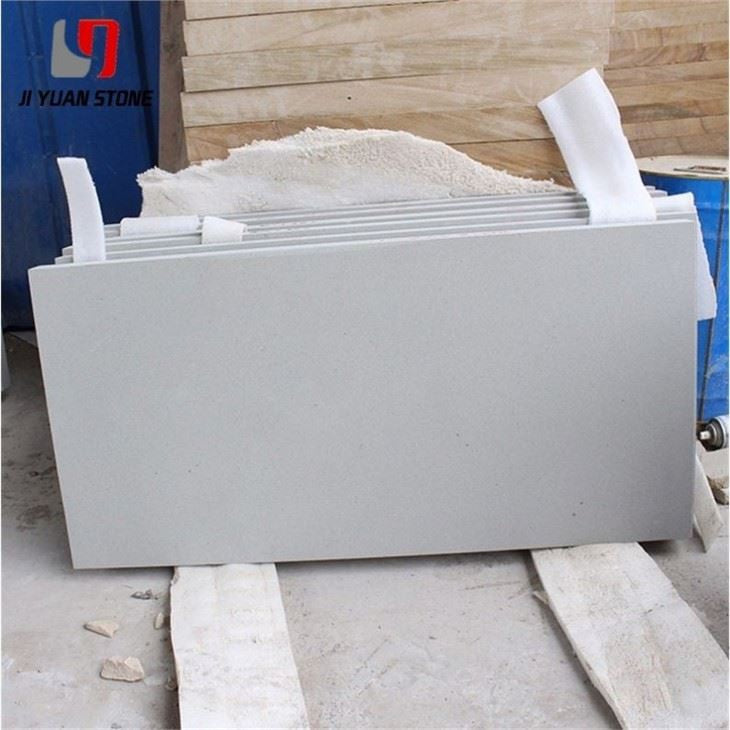

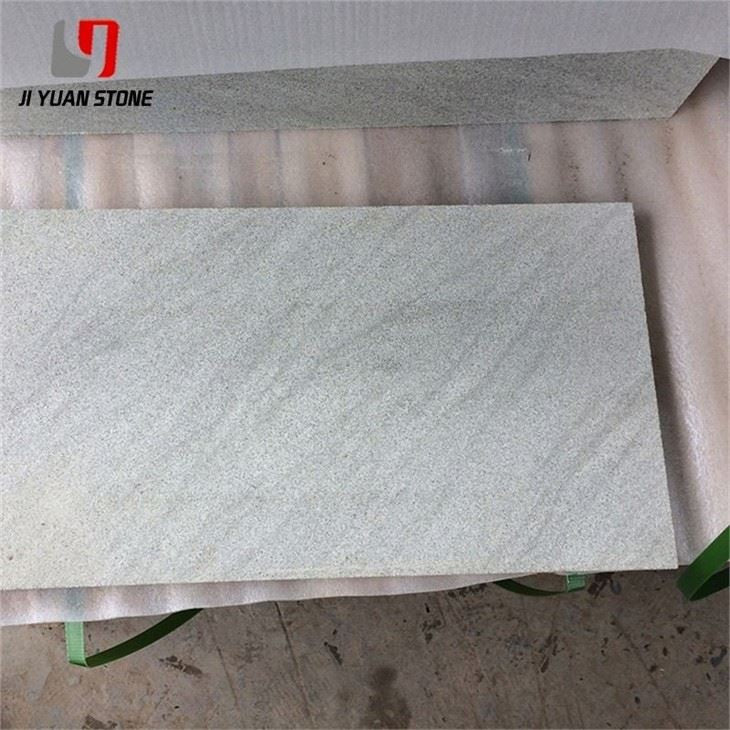

Transform your outdoor space with our durable Sandstone Patio. Crafted from high-quality sandstone material, this patio brings a touch of natural beauty to your home. With its strong and sturdy construction, it can withstand any weather conditions, providing a long-lasting addition to your outdoor living area.

| Feature | Details |

|---|---|

| Materia | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Size | Customized Pls contact us for the newest catalog of sandstone |

All sandstone products are manufactured to the highest quality international standards in our state-of-the-art processing factories, and then we securely packed, shipped and delivered for you. Our team is here to taking care and making sure that you always get the fastest and highest quality service.As a professional stone manufacture, we know quality is of the great importance, “Quality is the life of the factory, reputation is the foundation of business” which is our maxim. We have strict inspection program during each working procedure, block selection, processing, packing, marking, transportation…We promise: we will never deliver rejected goods to the clients! Currently, we have two plants which specialized in Basalt,Lava,granite products in China.Our products included the floor tile, slab, sink, swimming pool edge,window sill,cobblestone,crazy paver,walling cladding and so on. The finishing we can supply are Sawn,Honed,Flamed,Polished, Brush,Sandblasted, Bush-Hammered, Chiseled, Rock-Pitch Etc.

So come and see us. The beauty of natural stone can only be appreciated by seeing it first hand.And we are always updating our range, so a trip to our factory is worth it.

We can do much better because we are more professional and more committed!

Guidelines for Sandstone Patio and Travertine in Curtain Wall Engineering

When using sandstone or travertine for curtain wall engineering, the stone must first pass basic material property tests to ensure it meets the necessary conditions. Only then can it be processed into panel plates for construction.

Basic Requirements for Sandstone Patio Panels

1. Panel Thickness

- The flexural strength of a thicker slab is generally lower than a thinner one. However, because the load-bearing capacity increases proportionally to the square of thickness, thicker slabs are still more durable.

- Minimum thickness requirements based on flexural strength (fk):

- fk ≥ 8.0 MPa → Minimum thickness: 35mm

- 4.0 ≤ fk < 8.0 MPa → Minimum thickness: 40mm

- The standard deviation method should be used to determine the minimum flexural strength.

- Thickness tolerance: +2mm / -0mm (no negative deviation allowed).

2. Panel Size

- Due to the low strength of sandstone and travertine, panel size should not exceed 1.0m².

- Avoid using long, slender slabs, as they are prone to breakage during transport and installation.

- Best side ratio: 1:2, but should not exceed 1:3.

3. Surface Treatment

- Waterproofing is essential since sandstone and travertine absorb water.

- Use water-repellent coatings with organic fluorine or silicone-based paints to reduce water absorption below 1%.

-

Waterproofing application:

- For glued board seams → Waterproof only the outer surface.

- For open board seams → Waterproof all six sides.

- Large or excessive holes in travertine should be sealed before use.

- Apply waterproof treatment only after all grooves and holes have been machined, cleaned, and dried.

4. Back Composite Layer

- Sandstone and travertine are fragile and not highly weather-resistant.

- To prevent breakage and ensure safety, apply a back layer of fiberglass cloth or composite materials.

Handling Special Cases

In some cases, unqualified stone is purchased and installed due to lack of technical assessment. This poses serious risks.

For example, an Australian yellow sandstone was used for a 40m-high, 7000m² curtain wall without proper testing. Many slabs broke during transportation and were still installed after being bonded with epoxy glue. Eventually, the installed slabs cracked and tests showed:

- Minimum flexural strength = 2N/mm² (far below standard).

- Water absorption = like a red brick (excessively high).

- The stone did not meet curtain wall safety requirements.

To prevent catastrophe, the following remedial measures were taken:

✅ Remove all improperly installed panels.

✅ Eliminate all loose, damaged, or epoxy-glued slabs.

✅ Apply six-sided waterproof coating.

✅ Reinforce slabs with a 1mm thick fiberglass-resin composite layer.

✅ Attach aluminum framing to each slab with screws.

✅ Modify long slabs for better support & add aluminum pillars.

✅ Ongoing inspection for future cracks or damage.

These corrective actions significantly increased costs but were necessary to ensure safety.

Conclusion

When using sandstone patio panels and travertine in curtain walls, safety must always come first. Key steps include:

🔹 Conduct thorough technical feasibility studies before selecting stone.

🔹 Understand material properties and limitations.

🔹 Minimize panel sizes & avoid long slabs.

🔹 Use machinery for precise hole & groove cutting.

🔹 Ensure proper transport & installation techniques.

🔹 Apply waterproofing & reinforcement where needed.

Preventative measures are always better than costly repairs. Proper planning and adherence to safety standards will avoid major risks and ensure long-term structural integrity.

Share