Sandstone Panel Cladding

Sandstone Panel Cladding

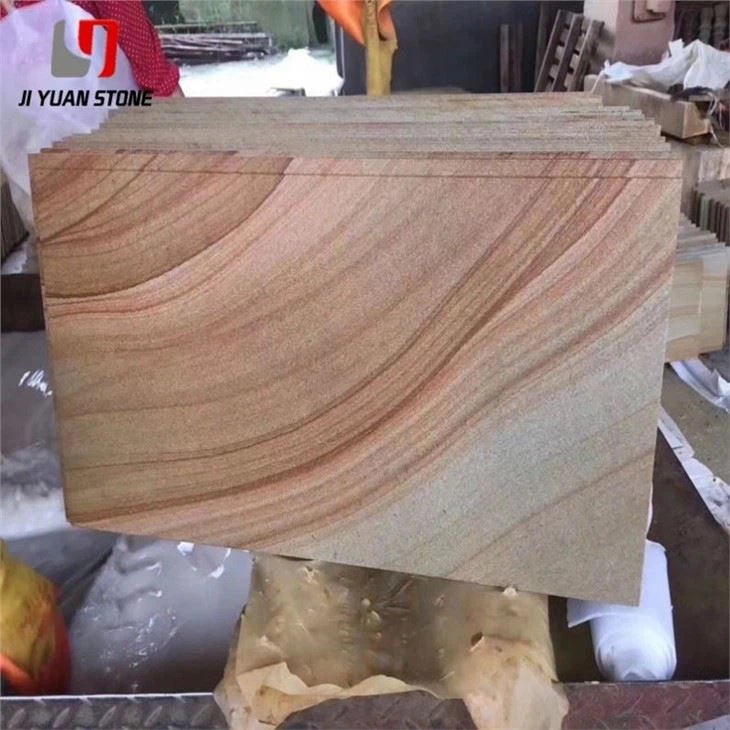

Premium Sandstone Panel Cladding – Precision-Crafted for Modern Architecture

Introduce unrivaled durability and elegance to your building with our Sandstone Panel Cladding. Made from natural sandstone, it boasts superior strength and timeless beauty, providing a long-lasting and visually stunning exterior. Upgrade your property with this top-quality cladding solution.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Sandstone panel cladding offers a timeless and durable solution for architectural facades, interior feature walls, and exterior building surfaces. Available in both smooth and sub-surface finishes, our high-performance cladding panels provide visual appeal and robust functionality for modern residential and commercial spaces.

Surface Options: Smooth vs. Sub-Surface Slate

Sandstone panel cladding is commonly available in two surface types:

- Smooth finish – Clean, polished look ideal for refined, minimalistic design.

- Sub-surface slate finish – A matte, textured appearance gaining popularity for contemporary projects.

Despite its aesthetic value, sub-surface slate comes with technical challenges. The texture exists only on the surface, and any chips or cracks become highly visible, even when repaired with colored glue. These repairs often lack uniformity, leaving noticeable inconsistencies that compromise the overall look.

Limitations of Slate Surface Restoration

Unlike ordinary polished stone, slate surfaces cannot be restored or re-polished. Manufactured under intense heat and pressure, slate lacks the flexibility of other stones. If the edge of the slab is chipped during transport or installation, the damage is permanent unless covered completely—an option not always viable.

- Blasted edges can be concealed only if they fall within a covered zone during installation.

- Cracks at perimeters or center seams are impossible to hide and require full slab replacement.

- On-site cutting with non-specialized tools leads to edge bursts, increasing material waste and visual defects.

Cutting & Installation Challenges

Sandstone panel cladding must be cut using specialized factory-grade blades. On-site cutting often leads to small, unintended edge bursts, further complicating the installation process. When visible cracks occur—especially on large panels—the only remedy is customer acceptance or full panel replacement.

However, this creates a cost burden for suppliers, as replacing large slabs often results in zero profit or financial loss. To maintain project timelines and customer satisfaction, minimizing cutting errors and selecting high-quality panels from the start is critical.

Why Choose Our Sandstone Panel Cladding?

- Available in smooth and sub-surface finishes for versatile design applications

- Cut and processed with precision to reduce risk of edge cracks

- Ideal for building facades, decorative walls, and cladding installations

- Made from durable, natural sandstone that resists weathering

- Factory-controlled production for consistent quality and fewer defects

Ideal Applications

- Commercial exterior facades

- High-end residential walls

- Hotel lobbies and entrances

- Interior accent walls

- Public building exteriors

Conclusion

When quality, precision, and appearance matter, Purchasestones’ sandstone panel cladding delivers lasting value. With careful handling and expert installation, our cladding offers elegant aesthetics and structural integrity, while avoiding the common pitfalls of slate surfaces.

Share