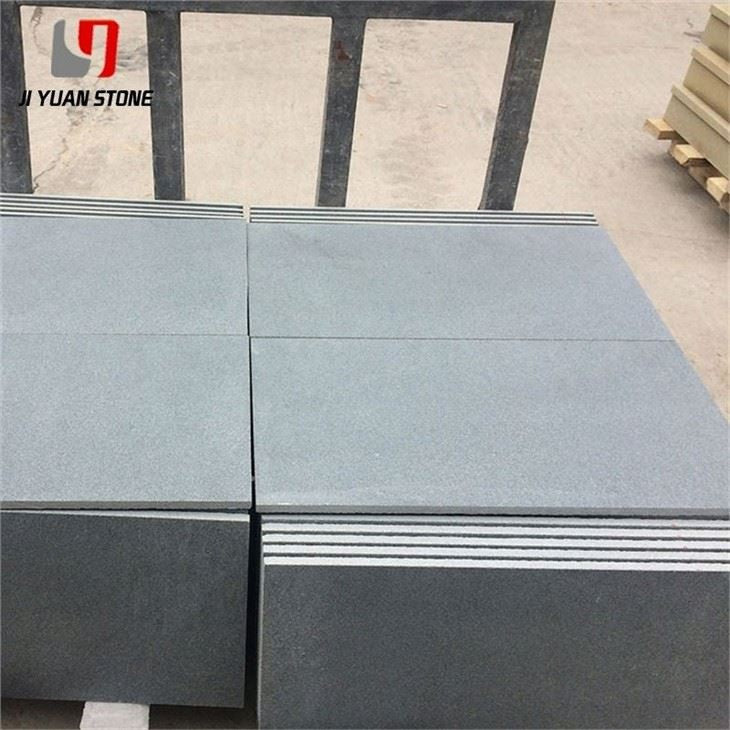

Sandstone Grey Slabs

Sandstone Grey Slabs

Sandstone Grey Slabs – The Perfect Blend of Strength, Style & Surface Precision

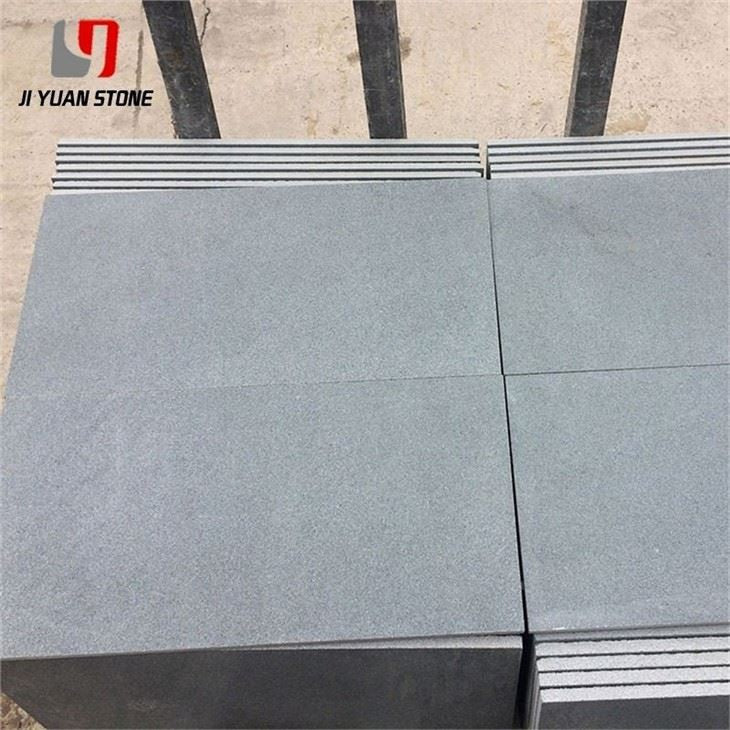

Improve your outdoor space with our Sandstone Grey Slabs. Made from high-quality sandstone, these slabs will enhance the appearance of your patio, walkway, or pool area. The durable material is perfect for withstanding all weather conditions, providing long-lasting beauty and functionality. Upgrade your outdoor living with Sandstone Grey Slabs.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

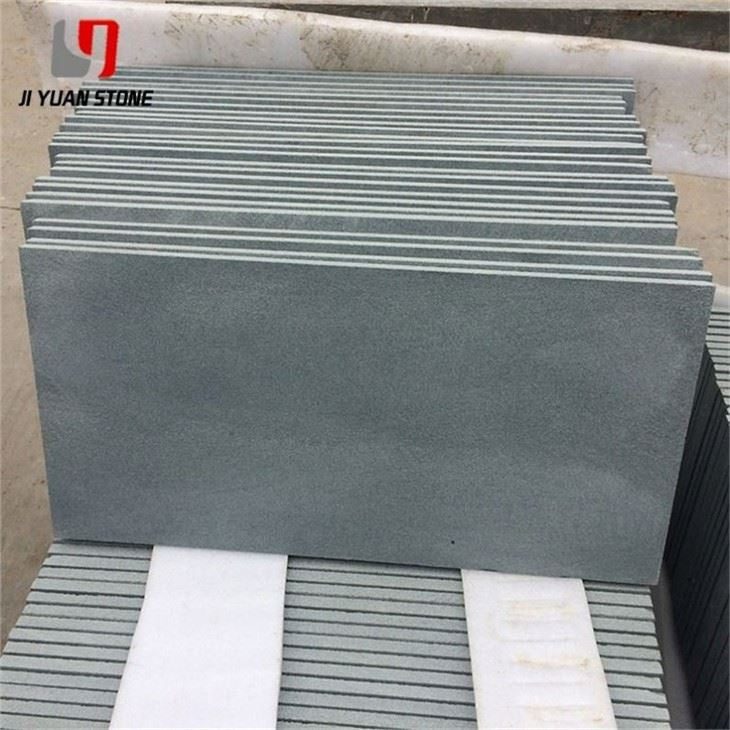

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

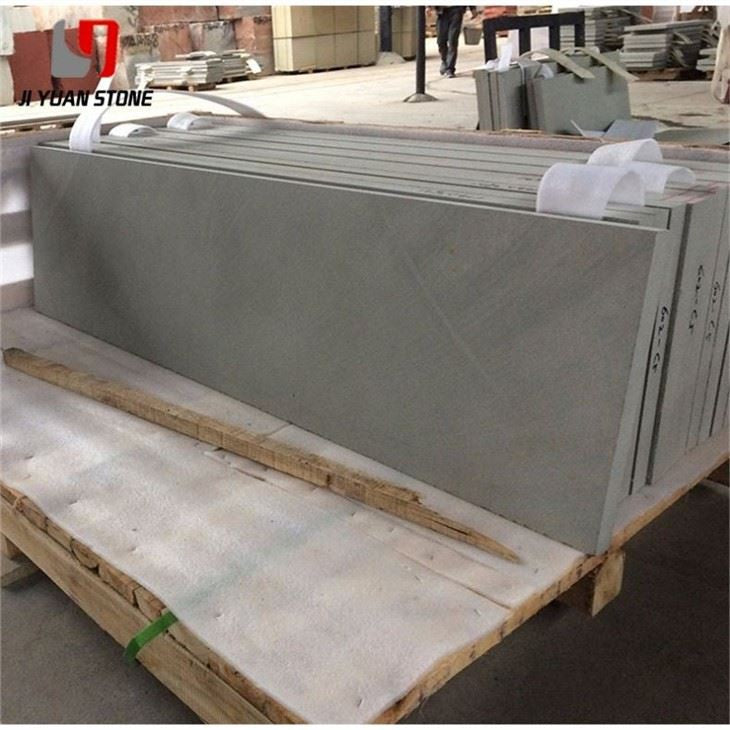

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Elevate your outdoor and architectural spaces with the natural elegance of sandstone grey slabs. Known for their sophisticated neutral tones, weather resistance, and durable surface properties, these slabs are ideal for patios, garden paths, walkways, courtyards, and commercial projects.

Their subtle grey coloration adds modernity while seamlessly blending with natural surroundings. Whether you're designing a contemporary outdoor setting or restoring a classic landscape, sandstone grey slabs deliver both aesthetic appeal and long-term functionality.

🔍 Key Construction and Installation Guidelines

To ensure top-tier results, the surface layer construction control of sandstone grey slabs should focus on multiple key aspects:

1. Sampling & Color Matching

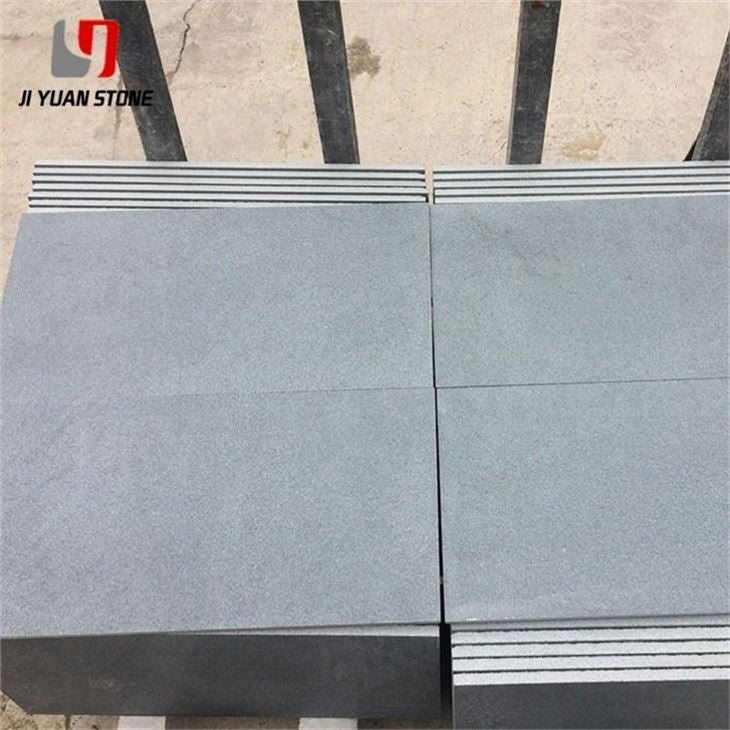

- Prioritize slabs with high color saturation to align with the pavement’s design tone.

- Conduct sample paving in advance to determine color harmony and ensure aesthetic consistency.

2. Material Selection & Source Control

- Rigorous screening is essential before materials arrive on-site.

- For projects with high aesthetic standards, assign dedicated personnel to oversee selection at the source.

- Buy from consistent suppliers to ensure uniform quality and color tone across all slabs.

3. Quality Processing & Cutting

- Only accept slabs with precise cutting, consistent dimensions, and minimal color variation.

- Reject products that show large color differences or surface defects to maintain visual integrity.

4. On-Site Paving & Layout Planning

- Workers should further screen and sort slabs on-site to eliminate mismatches.

- Monitor adhesive layer thickness, seam widths, and alignment to meet design expectations.

- A preserved sample paving section should be visible on-site to communicate quality benchmarks and technical requirements to all construction teams.

📏 Detailed Surface Control & Paving Techniques

- Seam Width Control: Maintain uniform joints using tools like spacers or hanging lines.

- Concave Seam Depth: Follow project-specific instructions to ensure aesthetic consistency.

- Pointing Skills: Use color-matched jointing agents for seamless integration.

- Finished Product Protection: Implement protective measures post-installation to avoid damage during other construction activities.

🌿 Why Choose Sandstone Grey Slabs?

- Natural & Elegant Appearance: Subtle greys enhance both modern and traditional spaces.

- Durability: Resistant to weathering and wear, suitable for high-traffic areas.

- Versatility: Ideal for outdoor landscapes, courtyards, driveways, and architectural projects.

- Low Maintenance: Easy to clean and maintain with excellent long-term performance.

🏡 Applications

- Garden walkways and stepping paths

- Poolside and patio areas

- Driveways and courtyards

- Commercial hardscapes and public parks

Sandstone grey slabs combine timeless aesthetics with professional-grade functionality. With proper planning, high-quality sourcing, and expert installation, these natural stone slabs offer enduring beauty and strength for any project.

Let the refined simplicity of sandstone grey elevate your next paving or landscaping design.

Share