Sandstone Grey

Sandstone Grey

Sandstone Grey Slabs – Expert Processing, Hole Forming & Quality Control

Sandstone Grey is the perfect choice for those looking for a durable and stylish option. With its natural sandstone color, it adds a touch of elegance to any space. Made of high-quality materials, it offers exceptional strength and longevity. Upgrade your decor with Sandstone Grey.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

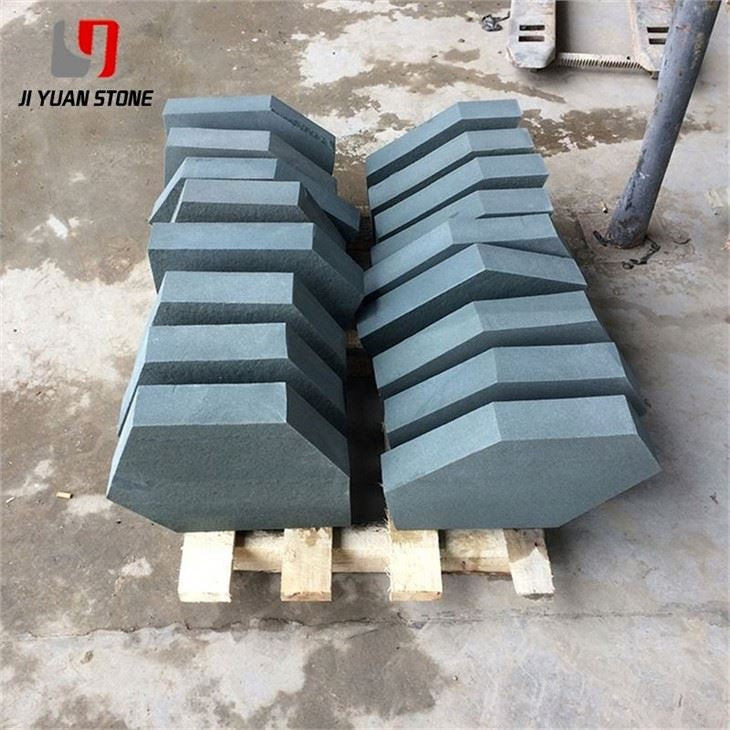

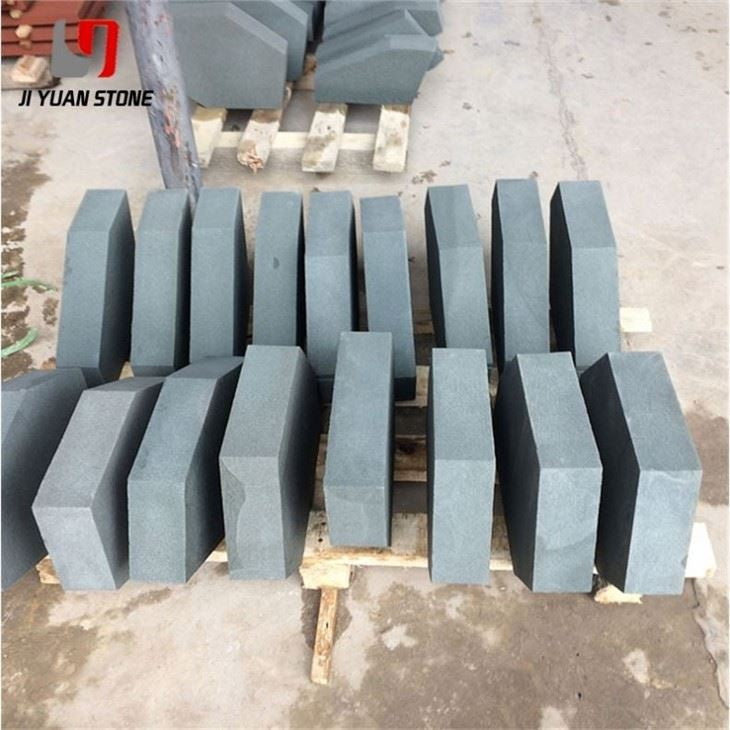

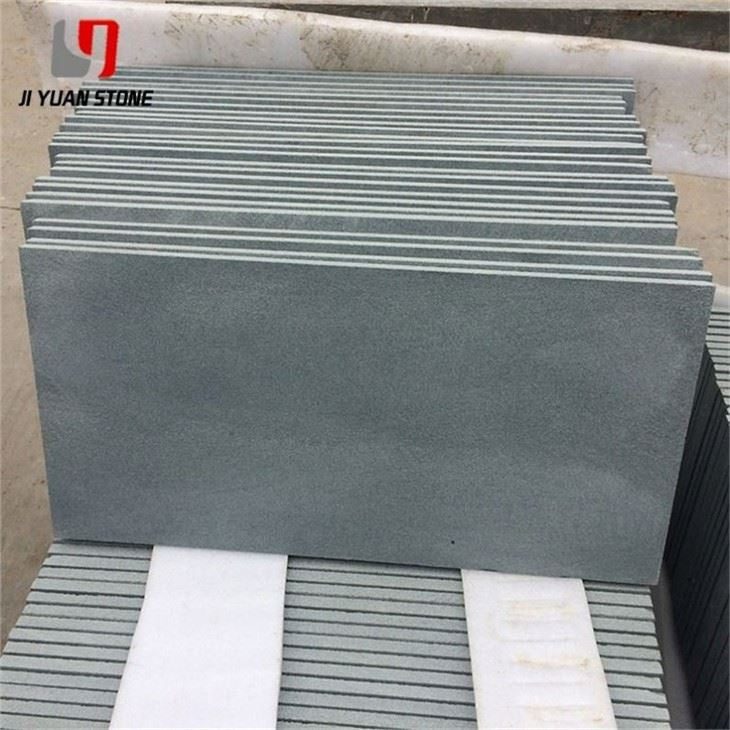

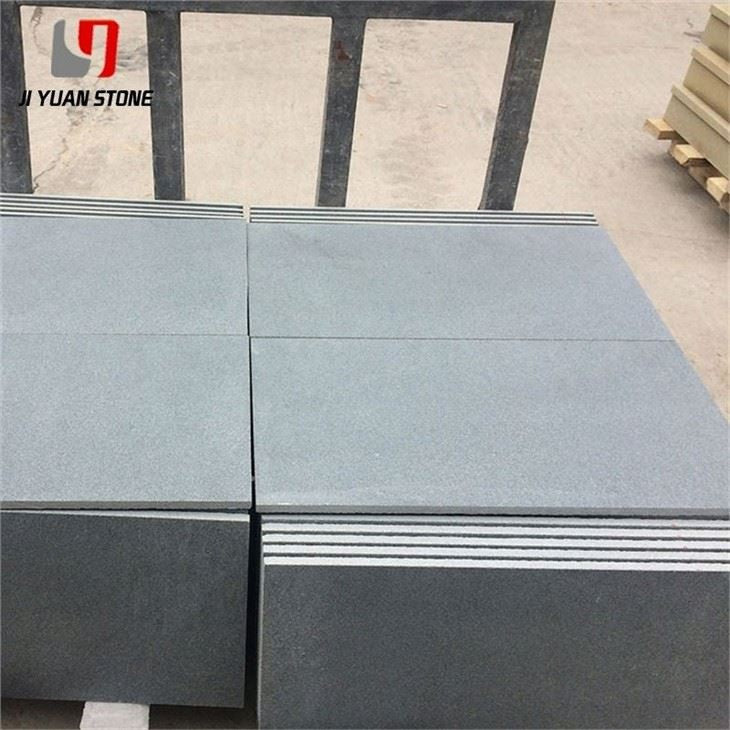

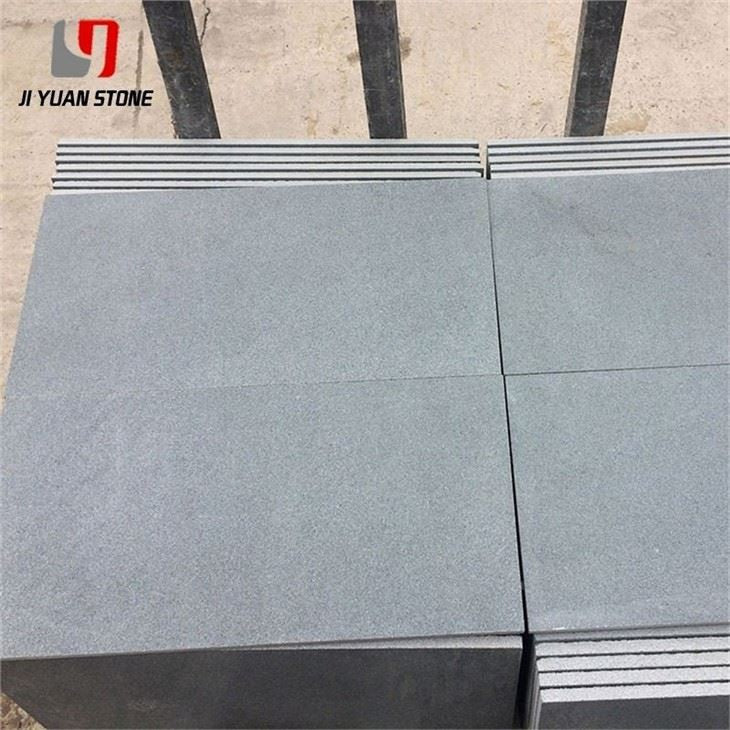

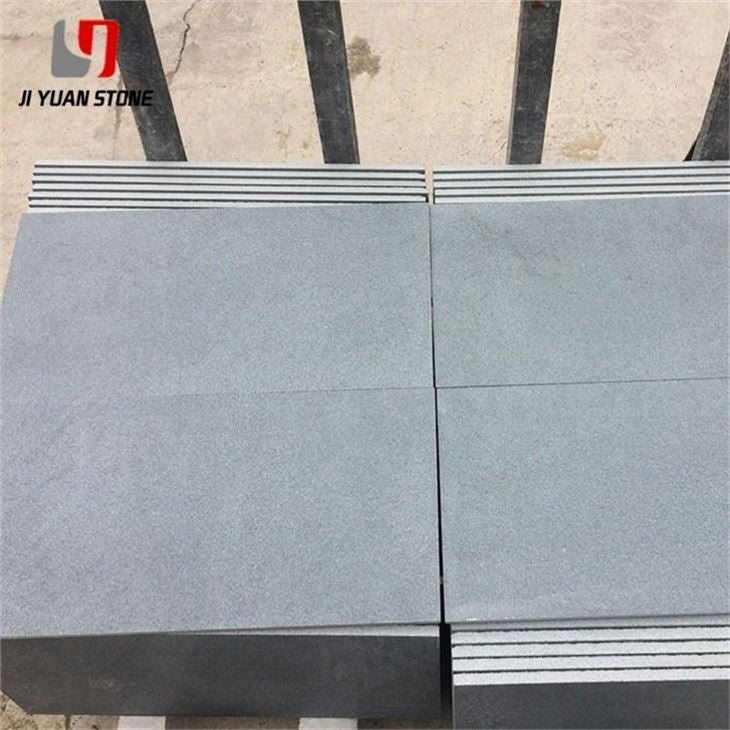

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

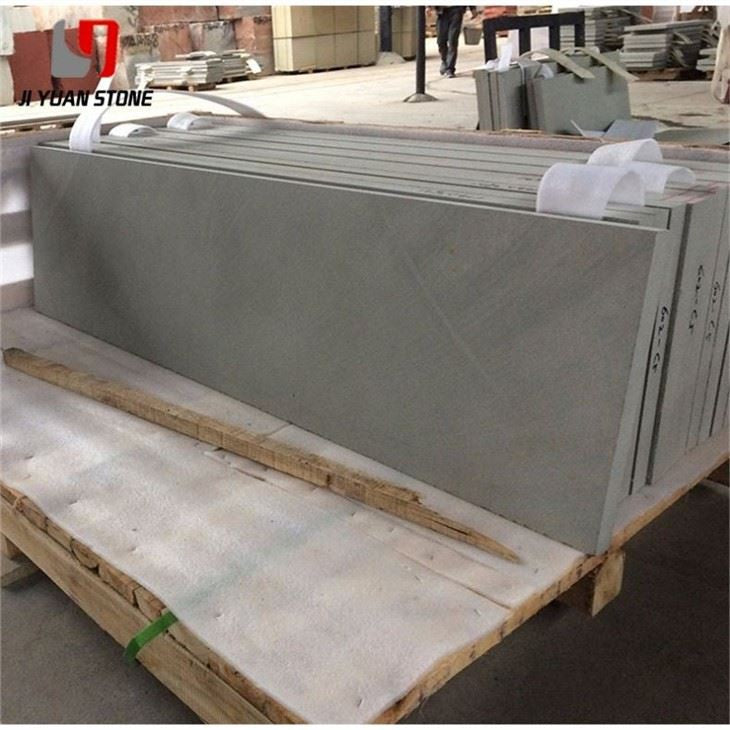

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Sandstone grey slabs are prized for their uniform color, elegant patterns, and versatility in construction and decoration. To maintain the highest quality standards, meticulous processing and hole forming procedures are essential.

🎯 Quality Control in Sandstone Grey Processing

Ensuring consistency and durability starts with strict quality checks:

- Inspect color difference, size deviation, and any damage thoroughly.

- Exclude any slabs with cracks, broken corners, missing corrugation, or noticeable color variations.

- Maintain uniformity in color and pattern across all stone slabs for a harmonious aesthetic appeal.

🔩 Advanced Hole Forming Process and Requirements

1. Hole Forming Steps:

- Use specialized equipment to grind precise columnar holes.

- Expand holes with precision tools to exact sizes.

- Clear debris carefully to ensure accuracy and avoid slab damage.

2. Hole Size & Placement Control:

- Hole placement is critical: edge distance must be between 100 mm to 180 mm, horizontal spacing no more than 600 mm.

- Sandstone grey slabs use special back bolt drilling equipment for precision.

- The upper and lower sides of the back of slabs are ground for better bolt fitting.

3. Drilling Equipment Specs:

- Back bolt drilling equipment operates at speeds up to 12,000 r/min with automatic frequency adjustment.

- Drill bits are matched to the bolt type and connection form.

- Air pressure hole forming technology prevents damage during grinding and expansion.

4. Final Quality Inspection:

- Check hole diameter, depth, and bottom surface post-drilling.

- Only slabs passing quality inspections proceed to back bolt installation.

⚙️ Technological Advancements and Cost Efficiency

Modern drilling technologies for sandstone grey slabs have not only improved precision but also significantly reduced hole forming costs, making quality slabs more accessible for various architectural projects.

By combining rigorous quality control and cutting-edge hole forming techniques, our sandstone grey slabs deliver unmatched reliability and aesthetic appeal for your construction and design needs.

Share