Sandstone Floor Slabs

Sandstone Floor Slabs

Sandstone Floor Slabs – Advanced Back Bolt Installation for Enhanced Safety and Longevity

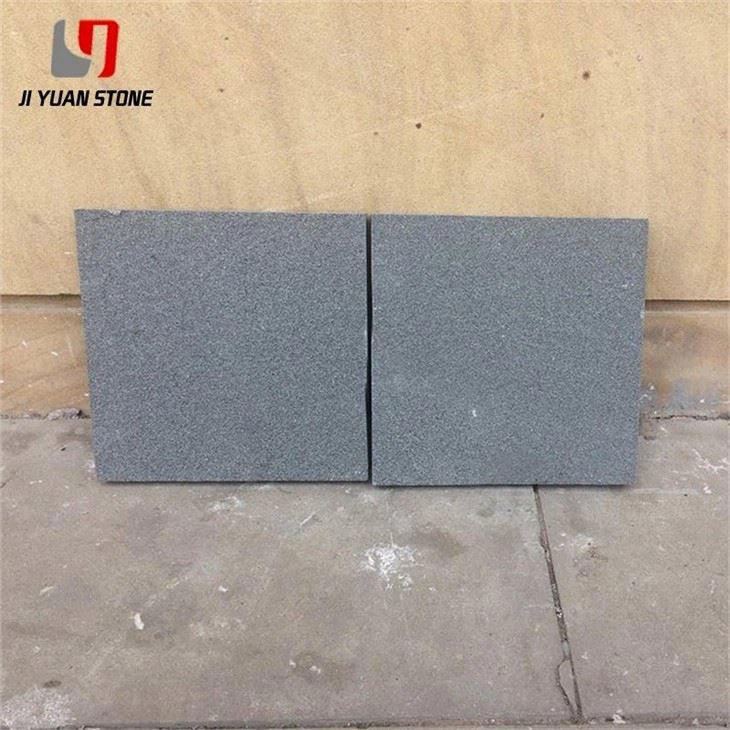

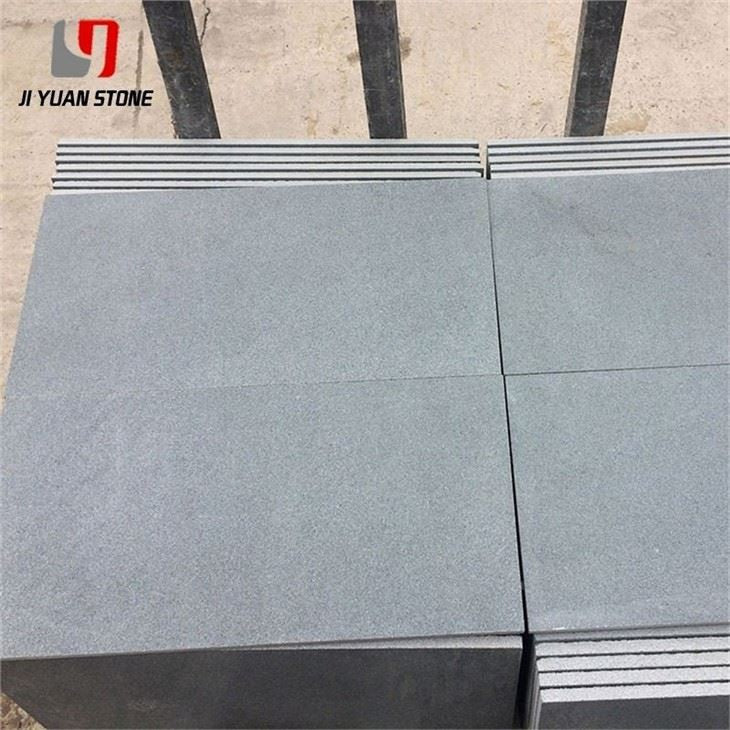

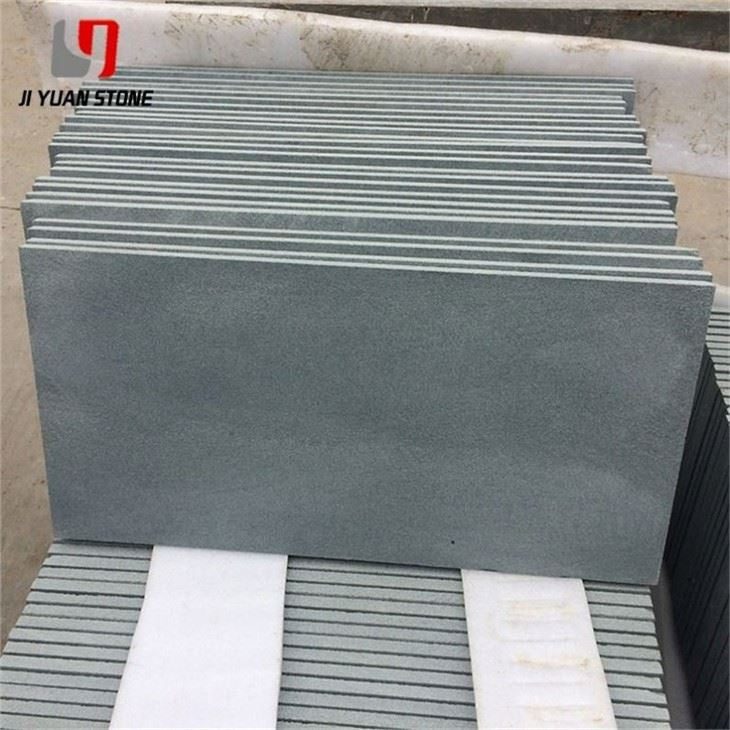

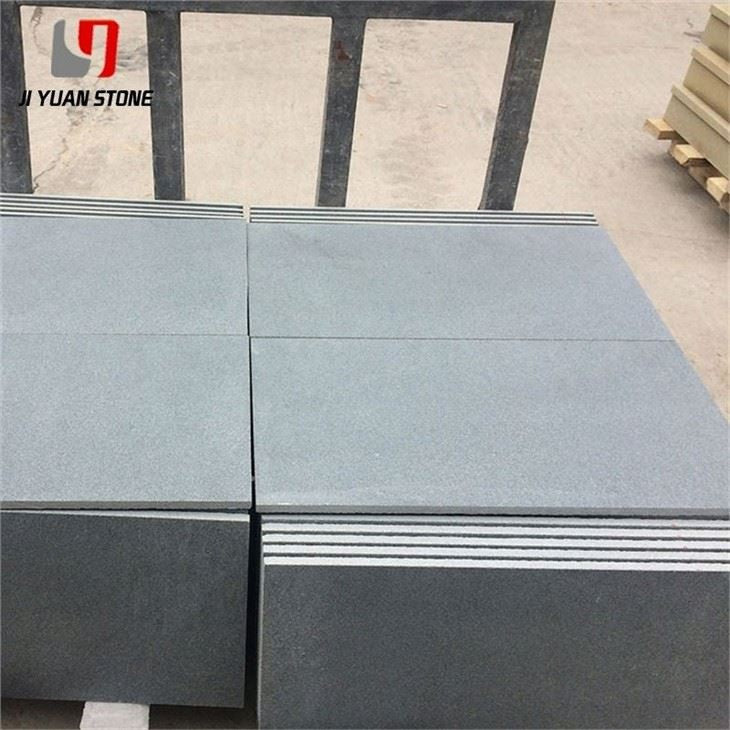

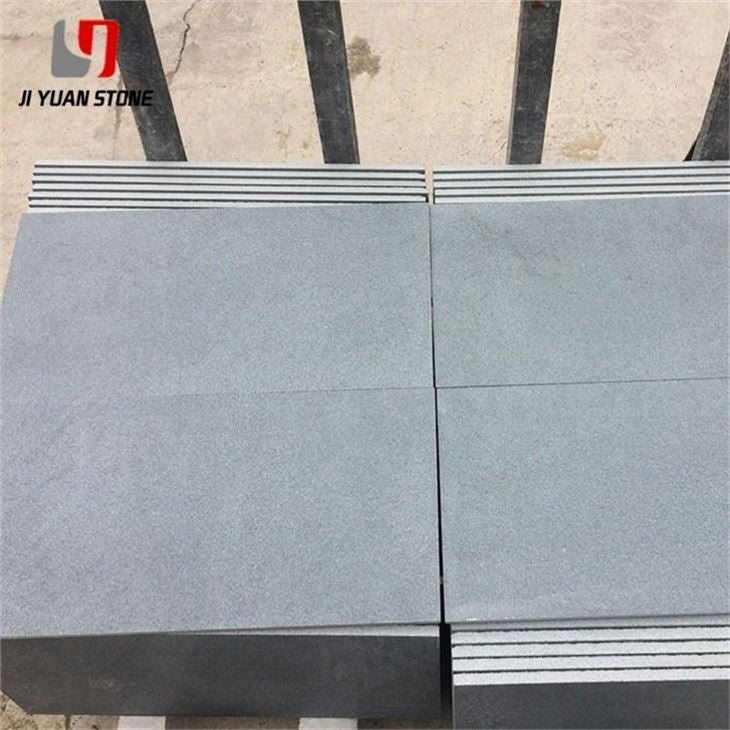

Experience the timeless beauty of our Sandstone Floor Slabs. Crafted from natural sandstone, these slabs add warmth and character to any space. With its durability and slip-resistant surface, they are perfect for indoor and outdoor use. Enhance your home or landscape with these stunning floor slabs.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

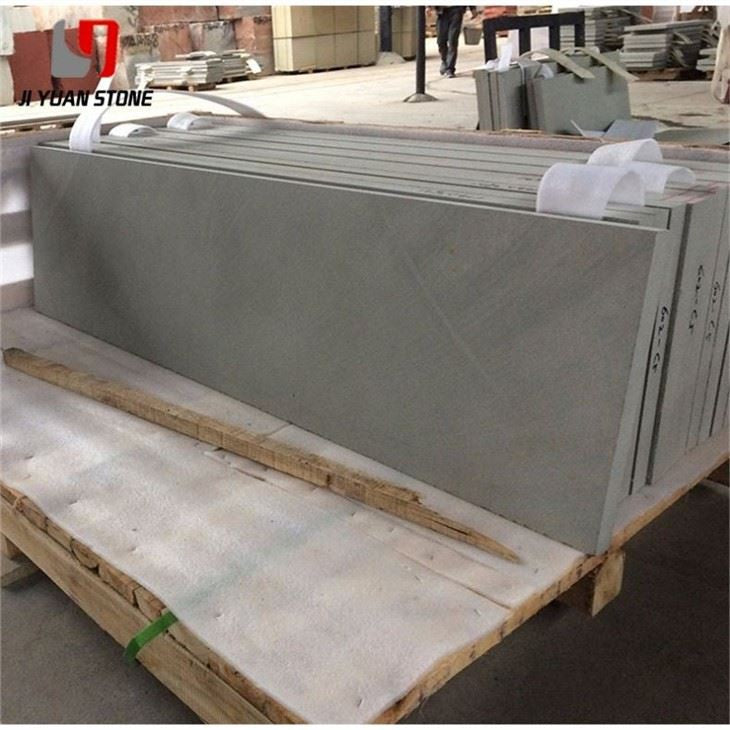

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

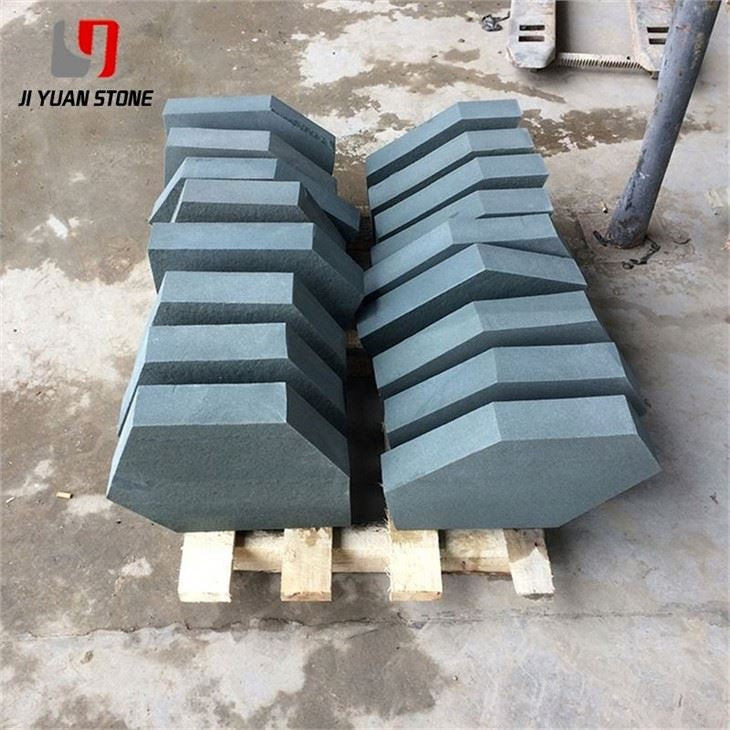

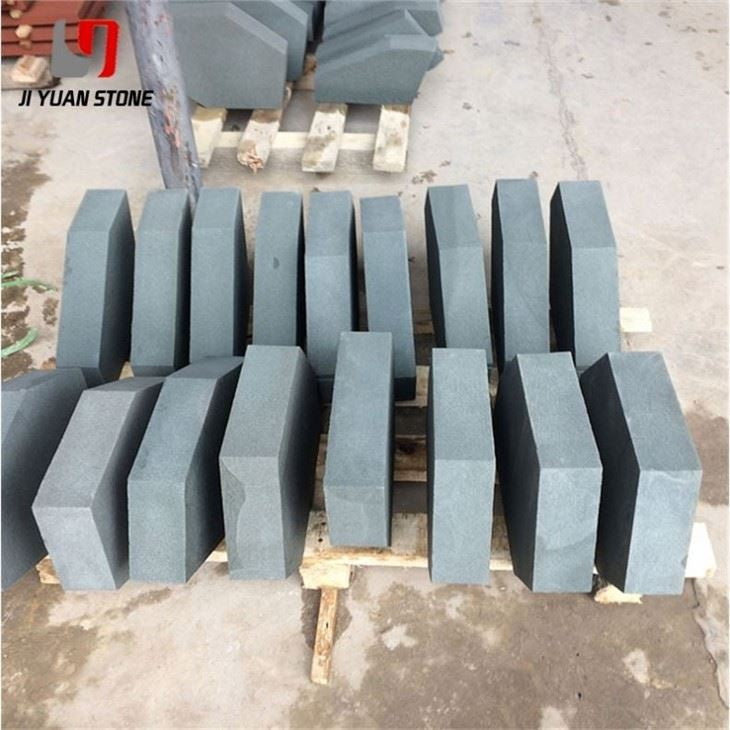

Our sandstone floor slabs are designed for independent installation and replacement, offering superior safety and performance for modern architectural projects. Each slab functions as a standalone unit, reducing stress from hard contact and improving wind pressure resistance, vibration resistance, and thermal expansion control — all contributing to a longer lifespan.

🔩 Innovative Back Bolt Dry Hanging Technology

The back bolt system used in these sandstone floor slabs provides higher load-bearing capacity compared to traditional installation methods. Precision hole formation is achieved through advanced factory processing, minimizing on-site adjustments and accelerating installation progress.

- Holes are drilled and expanded using air pressure hole forming technology, positioned 100-180mm from the slab edge.

- Nylon mesh sleeves allow flexible connection between slabs and the main structure’s skeleton, efficiently transferring forces.

🏗️ Installation and Maintenance Advantages

Independent slab units eliminate load reaction caused by rigid contact.

Flexible node methods simplify maintenance and replacement during the slab’s lifecycle.

Suitable for stone curtain walls on public buildings up to 100 meters high, and for seismic fortification intensity up to 8 degrees or non-seismic designs.

Before skeleton installation, the slabs undergo critical testing for:

- Wind pressure deformation performance

- Rainwater leakage prevention

- Air permeability (when required for thermal performance)

- In-plane deformation capability

⚙️ Construction Preparation

- Check embedded parts for position accuracy and firmness.

- Implement reasonable repair and compensation plans if deviations exceed standards, ensuring all components meet requirements before proceeding.

✅ Why Choose Our Sandstone Floor Slabs?

With their robust construction and precise engineering, these slabs offer enhanced safety, reduced structural stress, and convenient upkeep. They are ideal for high-quality architectural projects requiring reliable stone curtain walls and elegant natural stone flooring.

Invest in sandstone floor slabs designed for durability, efficiency, and aesthetic appeal

Share