Sandstone Floor

Sandstone Floor

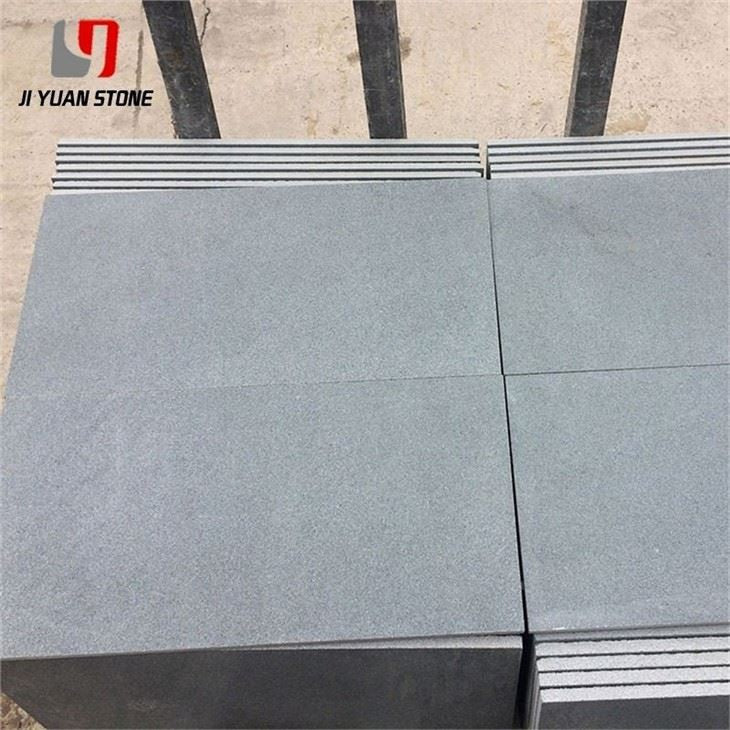

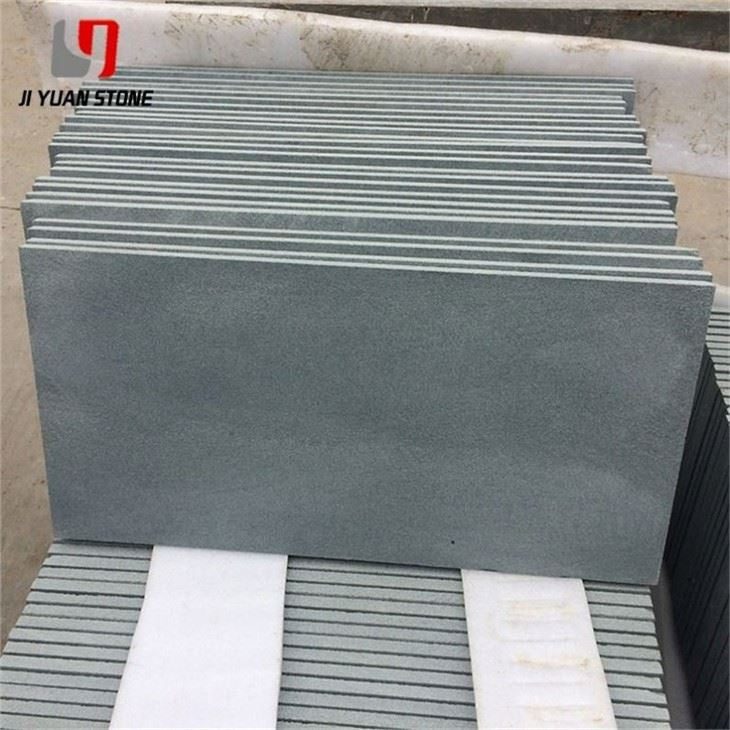

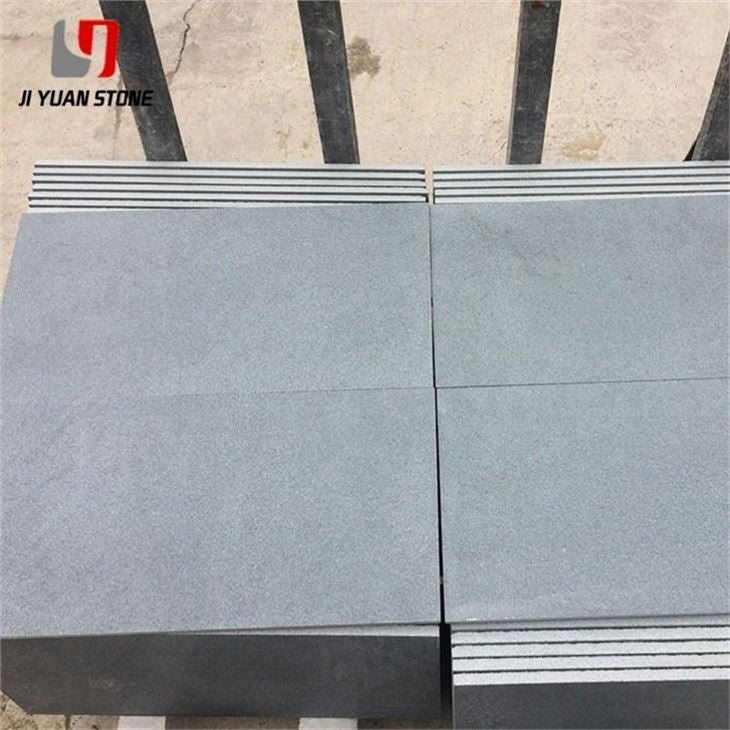

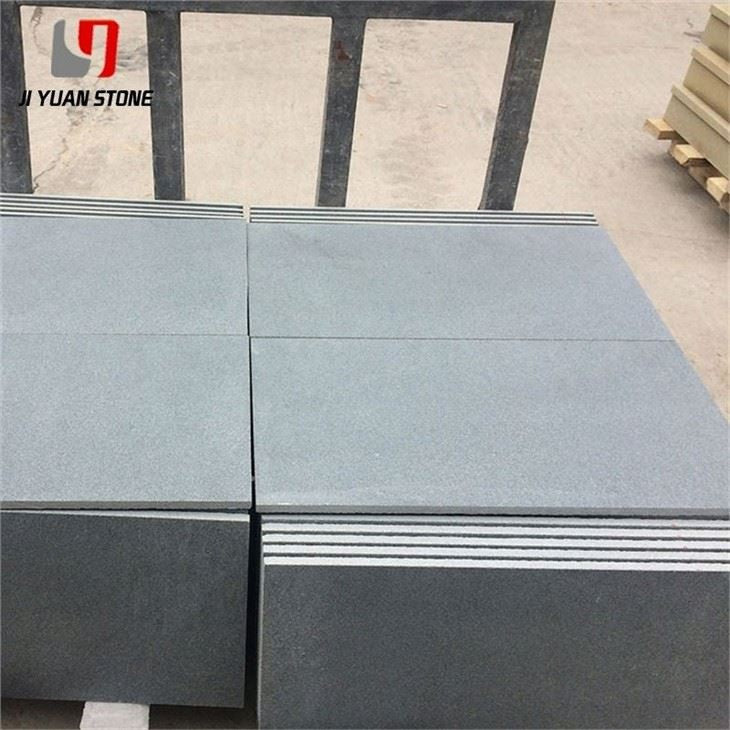

Sandstone Floor Tiles – Natural Beauty with Durable Performance

Upgrade your space with our high-quality Sandstone Floor. Made from natural sandstone, this stylish and durable flooring option will add a touch of elegance to any room. With its unique texture and easy maintenance, it's the perfect choice for both residential and commercial use.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

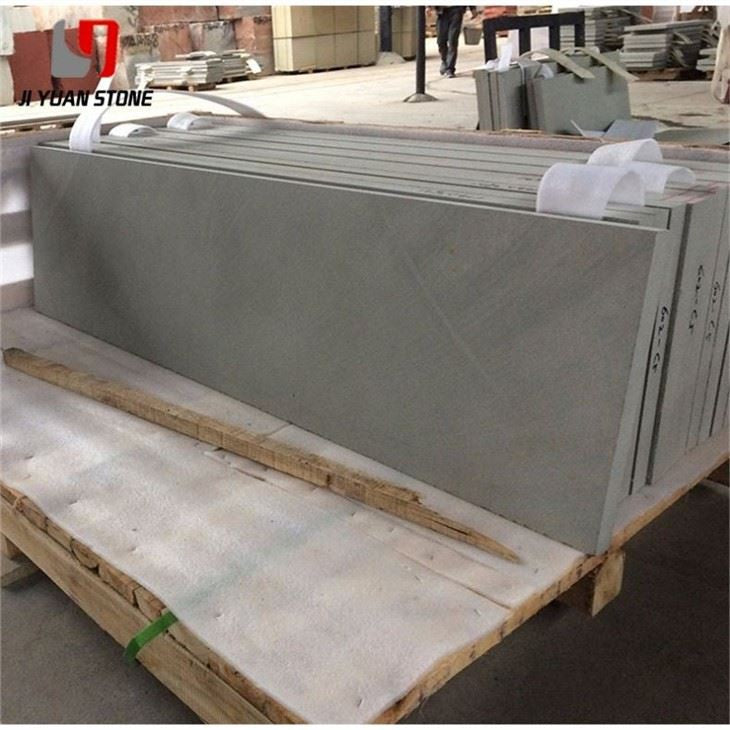

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Bring timeless elegance and earthy charm to your space with our premium sandstone floor tiles. Ideal for both indoor and outdoor use, these natural stone tiles offer rich textures, unique patterns, and a durable surface built to withstand daily wear.

While sandstone’s natural characteristics are part of its appeal, understanding its behavior after installation is critical to achieving a long-lasting, flawless floor.

🛠️ Common Issues with Sandstone Flooring – And How to Prevent Them

Many homeowners and designers are often puzzled when carefully selected sandstone flooring begins to show signs of wear or damage. Those beautiful, polished slabs seen in showrooms or digital renderings can appear drastically different after installation due to several overlooked factors:

1. Dry & Dark Cracks in Natural Stone

Natural sandstone often contains dry or dark cracks hidden beneath its textured beauty. While these imperfections are generally invisible in showroom conditions, exposure to moisture, foot traffic, or harsh sunlight after installation can lead to surface lesions or discoloration.

2. Inadequate Crack Treatment

Most visible cracks are filled with instant glue, which offers fast curing but lacks deep penetration. During grinding or polishing, this superficial fill often results in incomplete coverage, leading to long-term surface damage.

3. Backside Waterproofing Limitations

Manufacturers typically apply a waterproof adhesive to the back of the large slabs, which has high viscosity but poor permeability. It does not fill the hidden cracks underneath, leaving them vulnerable. Without thorough treatment, water infiltration and stress cracks are likely to develop after installation.

🧱 Key to a Durable Sandstone Floor: Processing & Installation

While we cannot alter the natural properties of sandstone, we can minimize defects through careful processing, professional treatment, and installation planning:

✔️ Crack Repair During Processing

- Slabs should undergo deep crack repair techniques beyond instant glue.

- Transparent resins or epoxy-based fillers provide better absorption and long-lasting reinforcement.

✔️ Surface & Edge Protection

- Before delivery, slabs are protected on all four edges and the front side.

- For better durability, we recommend additional backfill reinforcement before on-site installation.

✔️ Professional Handling & Paving

- Avoid secondary, on-site processing unless by experienced craftsmen.

- Proper waterproofing, adhesive use, and care during paving will drastically reduce the chance of post-installation lesions.

🌟 Why Choose Our Sandstone Floor Tiles?

- Authentic Natural Patterns: Each tile is one-of-a-kind, showcasing the natural charm of sandstone.

- Eco-Friendly & Sustainable: A natural material that’s both durable and environmentally responsible.

- Versatile Use: Suitable for living rooms, kitchens, patios, and commercial spaces.

- Timeless Aesthetic: Neutral, earthy tones blend beautifully with a variety of interior and exterior styles.

📌 Key Applications

- Residential flooring

- Commercial lobby areas

- Outdoor patios and verandas

- Hotel and resort interiors

- Cultural or heritage sites

Choose sandstone floor tiles not just for their beauty, but for their story. With the right care and thoughtful installation, these natural stone slabs will reward you with decades of stunning performance and style.

Looking for professional guidance on proper sealing, installation tools, or long-term maintenance tips? Let us know—we're here to help maximize your sandstone investment.

Share