Roman Travertine

Roman Travertine

Roman Travertine – Timeless Strength, Precision-Crafted for Russian Markets

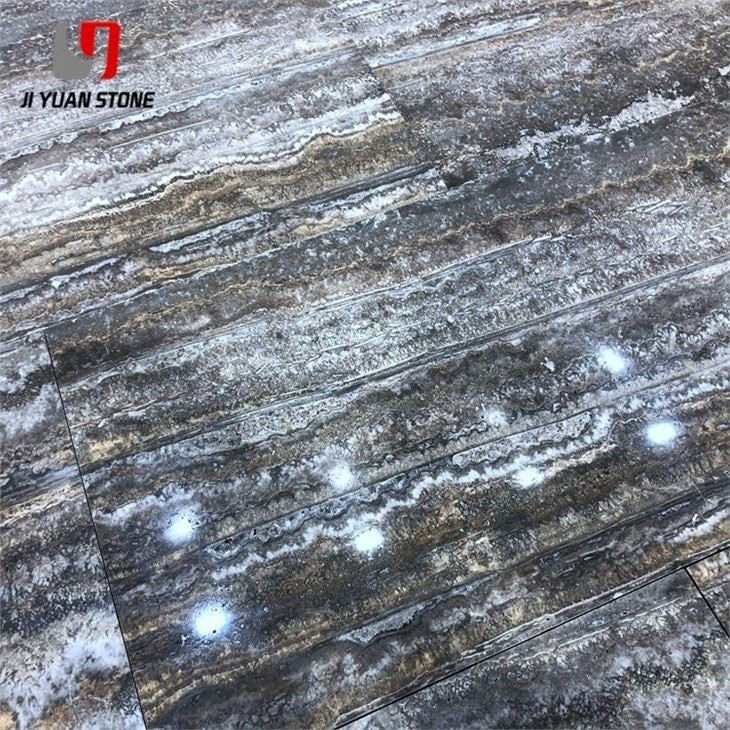

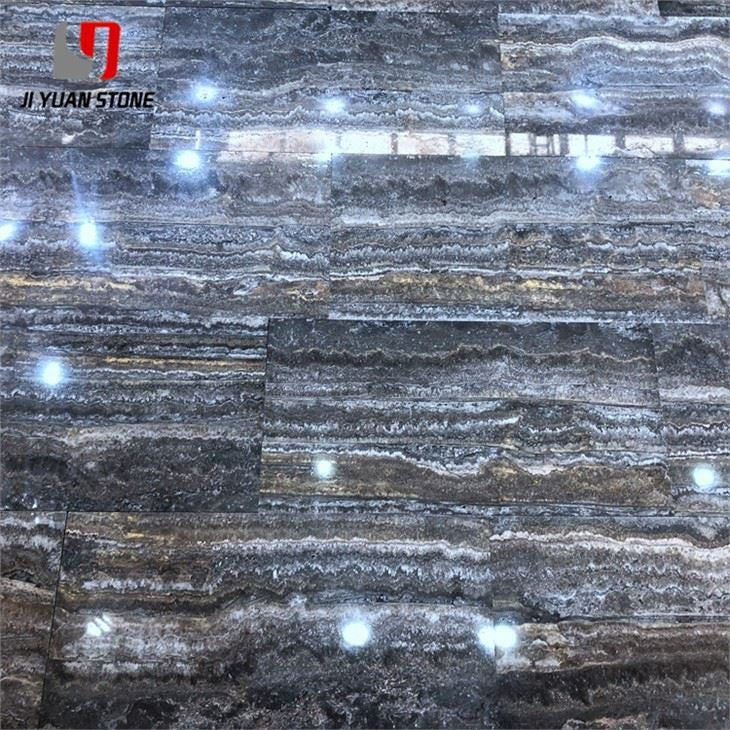

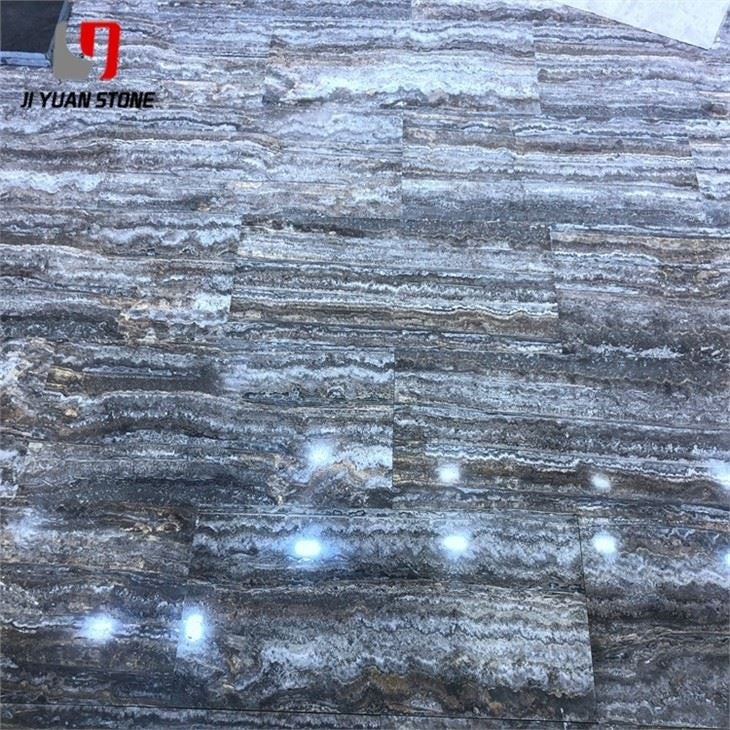

Roman Travertine is a highly durable and versatile natural stone perfect for interior and exterior design projects. Its timeless beauty and unique color variations make it a popular choice for flooring, countertops, and wall cladding. With its impressive strength and luxurious appearance, Roman Travertine brings elegance and sophistication to any space.

| Feature | Details |

|---|---|

| Material | Natural travertine |

| Colour | Silver, Grey |

| Thickness | 15mm , 16mm , 18mm , 20mm or customized |

| Slab sizes |

|

| Tile sizes | 300x300mm ; 600x600mm; 450x450mm etc |

| Surface | Polished |

| Edge processing | Machine cutting, round edge etc |

| Packing | Seaworthy wooden crate, pallet |

Known for its historical elegance and exceptional durability, Roman Travertine remains one of the most sought-after stones in modern architecture. Whether for residential use or public buildings, this stone’s classic look and structural strength make it a popular choice—especially in climates like Russia where freeze-thaw conditions demand thicker, high-performance material.

📦 Russian Plate Market & Roman Travertine Construction Techniques

✅ Russian Plate Market Overview

Russia’s demand for Roman Travertine has grown consistently, with evolving acceptance of varied sizes and thicknesses due to industry competition and performance needs.

-

Preferred Thickness:

The Russian market primarily uses 2cm thick plates. While 1.8cm plates were initially rejected, they’re now accepted thanks to pricing competitiveness from Shuitou exporters.

Common Sizes:

- 300×300mm

- 305×305mm

- 400×400mm

- 300×600mm

- 400×600mm

- 400×800mm

(Larger sizes are used less frequently due to thickness and durability requirements.)

Thickness Variations by Use:

- Standard boards: 2cm thick

- Small-format tiles: 1cm–1.5cm thick

- Large slabs or custom pieces: up to 2.5cm or 3cm

🛠️ Deep-Processed Product Demand in Russia

Russian buyers often request deep-processed Roman Travertine, making it essential for suppliers to meet a broad range of custom fabrication needs, including:

- ✔️ Special-shaped travertine panels

- ✔️ Sculptural carvings

- ✔️ Tombstones

- ✔️ Fireplaces

- ✔️ Wash basins & countertops

- ✔️ Door & window casings

🧼 Roman Travertine Renovation & Grinding Techniques

Due to the porous nature of Roman Travertine, specific polishing and waterproofing steps are critical for longevity and aesthetics.

🧩 Step 1: Joint Filling Before Polishing

- Ensure tight seams and structural integrity.

💧 Step 2: Pre-Caulking Waterproof Treatment

- Why? Polishing introduces water into the pores.

- Problem: Trapped moisture causes water spots, back alkali, white blooms, and yellow stains.

- Solution: Allow stone to dry thoroughly before sealing.

🔒 Pro Tip: Double Waterproofing

- For high-moisture areas or outdoor use, apply a second waterproof layer after 800# grinding to lock in durability and prevent discoloration.

🏗️ Why Choose Our Roman Travertine?

- ✅ Russian market–approved thickness & sizing

- ✅ Highly workable for carvings, countertops & architectural elements

- ✅ Expert grinding and sealing processes

- ✅ Available in custom cuts and bulk orders

- ✅ Competitive pricing from trusted quarries

Bring classical sophistication and proven durability to any space with premium Roman Travertine slabs—built to withstand, designed to impress.

✔️ Built for Russian climates. ✔️ Processed with care. ✔️ Ready for custom use.

Share