Red Travertine Polished

Red Travertine Polished

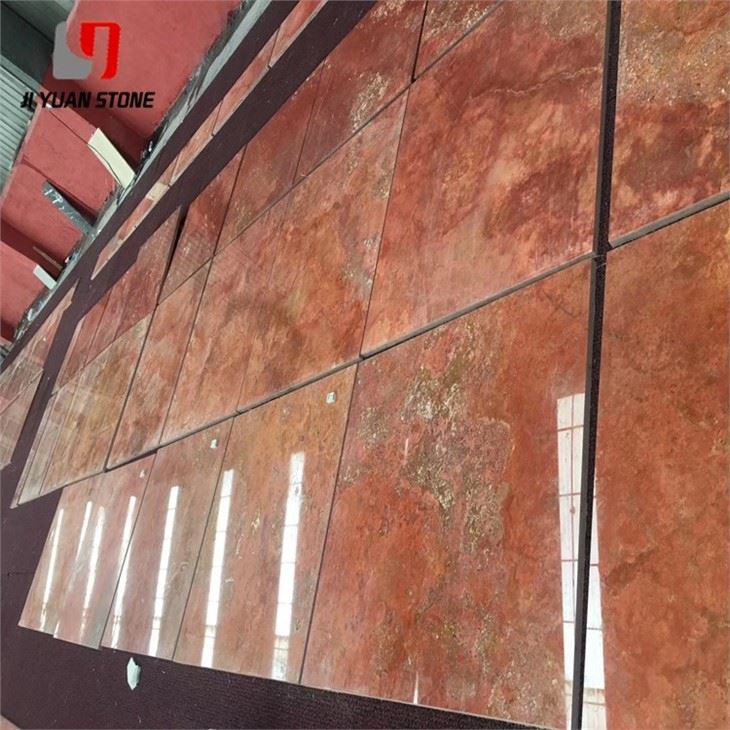

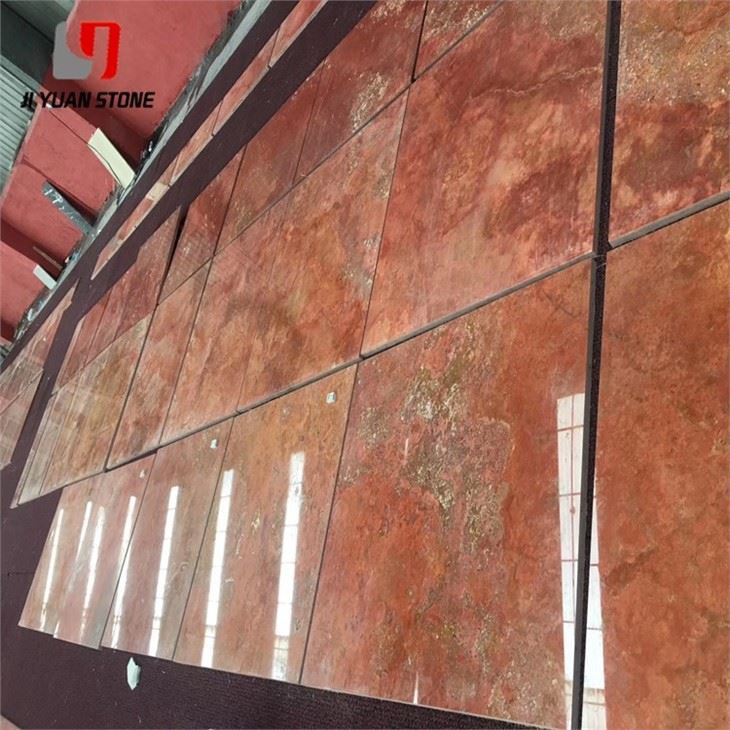

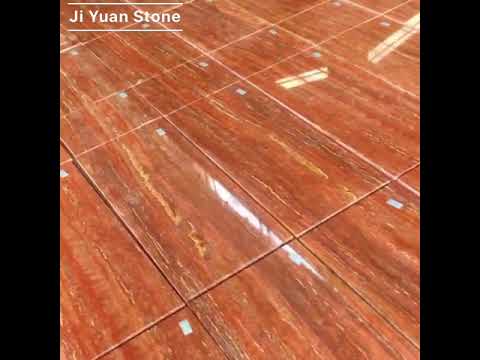

Red Travertine Polished – Natural Elegance with Lasting Appeal

This red travertine boasts a stunning polished finish, adding a touch of elegance to any space. With its natural color variations and durable composition, it is a reliable and beautiful choice for any interior or exterior design project. Enjoy the benefits of a unique and timeless stone that will enhance the aesthetics of your home or business.

Red Travertine Polished is a striking and timeless natural stone that blends deep red tones with unique textures formed by mineral deposition over centuries. Scientifically classified as "travertine," this stone consists mainly of calcium carbonate and is renowned for its vibrant color, characteristic holes, and polished finish. Its distinctive porous surface is the result of either natural bubbles or fossil remains that leave behind voids as the stone forms.

Red Travertine Polished Analysis

The natural charm of Red Travertine Polished lies in its simplicity, earthy elegance, and suitability for both indoor and outdoor applications. It’s widely used in wall cladding, flooring, and decorative stone projects, making it a favorite among architects and interior designers.

However, due to its porous nature, this stone is prone to collecting dirt, sustaining scratches, and losing gloss over time. Additionally, during installation, glue used to patch the holes may react with external elements—turning black in beige travertine and blue in red travertine polished—if not applied correctly.

Technical Solutions for Longevity & Gloss Restoration

To restore its natural beauty and enhance durability, a precise treatment process is recommended. This method includes deep cleaning, grinding, light curing, and crystal hardening.

1. Engineering Standards

- Pollution Cleaning: Effectively remove contaminants embedded in the holes to restore the stone's natural look.

- Overall Treatment: Perform a squeegee and light-curing treatment to fill holes using color-matching glue.

- Crystal Hardening: Achieve anti-fouling and anti-seepage properties with a surface gloss level ≥85 degrees for a polished finish.

2. Construction Process

Step 1: Protection of Finished Products

All nearby surfaces and items are covered with plastic film and masking paper to prevent dust and mud contamination during the cleaning and grinding process.

Step 2: 50# Grinding Disc Treatment

- Dry Milling: Not recommended due to dust accumulation in pores.

- Water Milling: Preferable method using VD marble super milling sheets and VD composite silane protective agent (1:20 ratio). Constant water pumping ensures optimal results.

Step 3: 46# Antique Abrasive Brush

Utilize a crystal surface machine equipped with a 46# antique grinding brush to remove old glue, break off fragile edges, and thoroughly clean embedded impurities.

Step 4: Drying with Fans

Accelerate drying using blowers placed every 20–30 meters. Maintain airflow by opening doors, windows, and vents to ensure the area remains dry and well-ventilated.

Why Choose Red Travertine Polished?

- Elegant, luxurious appearance with a vibrant red hue

- Versatile use for both interior and exterior designs

- Durable and long-lasting with the proper treatment

- Enhances the aesthetic and value of any space

Bring out the best in your architectural design with Red Travertine Polished – a perfect blend of nature, tradition, and modern treatment expertise.

Share