Red Travertine Pavers

Red Travertine Pavers

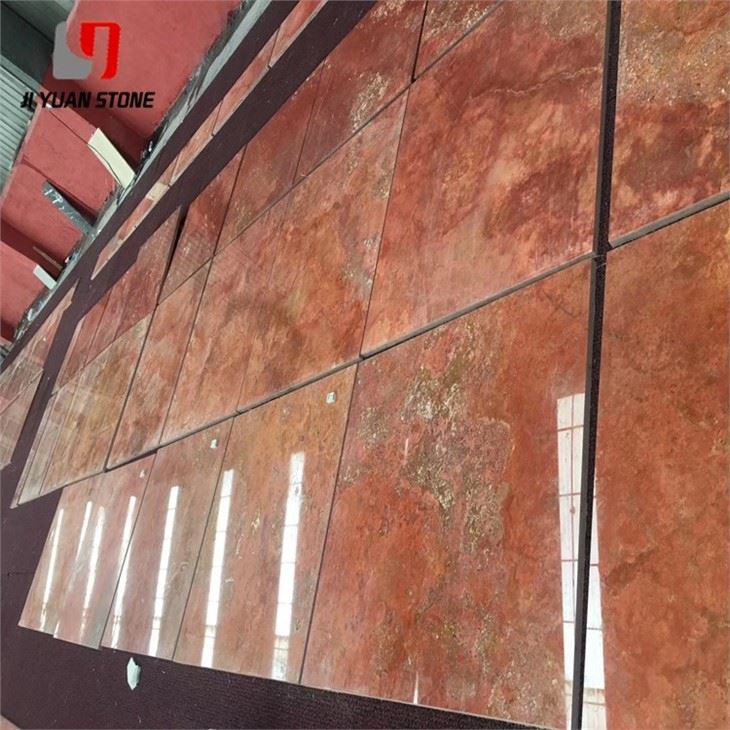

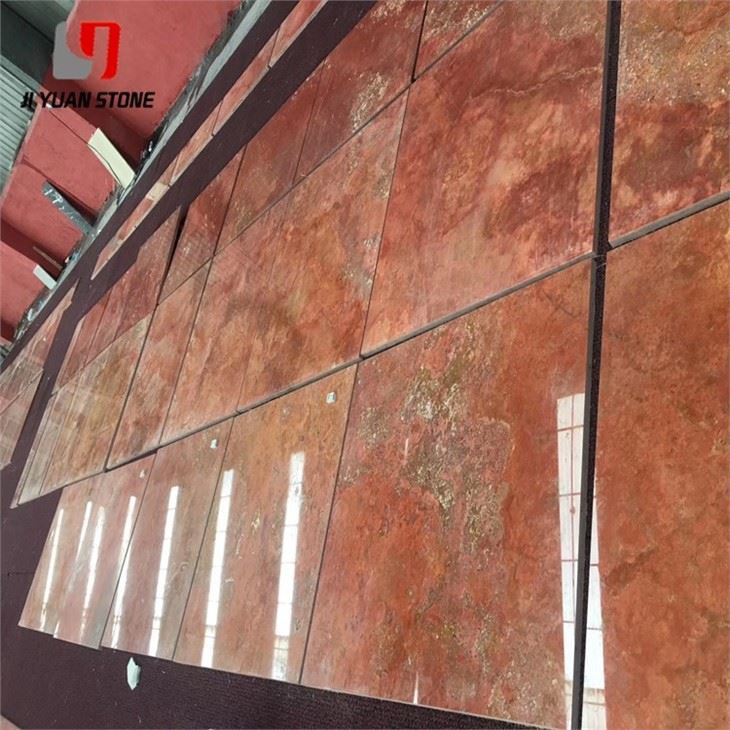

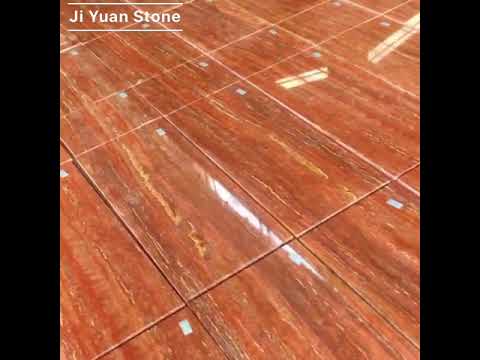

Red Travertine Pavers – Rich Color, Natural Character

Expertly crafted, our Red Travertine Pavers provide a stunning and durable addition to any outdoor space. With its unique red tones and pitted surface, these pavers offer both visual appeal and natural slip resistance. Upgrade your patio or walkway with these high-quality pavers.

| Feature | Details |

|---|---|

| Product Name | Red travertine |

| Matrials | Marble |

| Sizes | 1800upx1200upx18mm,600x600x18mm |

| Surface/Finish | Honed |

| Usage | Inside wall and flooring |

| Payment Terms | T/T L/C |

Bring timeless beauty to your landscapes with Red Travertine Pavers, a naturally vibrant stone perfect for outdoor paving projects like patios, pathways, and pool surrounds. Known for their stunning red tones and rustic charm, these pavers deliver a distinctive and luxurious finish. However, understanding their natural limitations is essential for maximizing their long-term performance.

Disadvantages of Red Travertine Pavers Materials

While red travertine pavers are prized for their aesthetics, they also come with some challenges due to their geological composition and surface characteristics.

1. Cracks Are Common in Red Travertine Pavers

Travertine naturally forms with grain lines, and in red travertine pavers, these lines act as fault zones. Cracks are prone to develop along these grains, especially during transport or heavy-duty use. The surface of red travertine is often filled with visible holes and fissures (as shown in Figures 3 and 4), which impact both its durability and overall strength.

Poor handling or processing of travertine can further weaken the material, affecting not just its physical integrity but also its aesthetic finish. Proper cutting, filling, and sealing are essential to minimize the risk of breakage.

2. The Adverse Effects of Holes on the Travertine Surface

The iconic pores in red travertine are part of its natural charm—but they also make the stone more susceptible to contamination and moisture damage. Dirt, dust, and water can easily collect inside these holes, degrading the stone over time.

When used as flooring, unsealed holes allow contaminants to seep into the paver, accelerating surface wear and reducing visual appeal. Even when sealed, the protective layer tends to wear away with foot traffic, revealing holes once again. Figures 5 and 6 illustrate repair techniques using cement, glue, and stone powder, but these solutions are only temporary.

Maintenance & Recommendations

To optimize the performance of red travertine pavers:

- Apply a High-Quality Sealant to protect against water absorption and staining

- Use Professional Installation methods to minimize structural stress

- Perform Regular Maintenance to re-seal and fill exposed pores as needed

- Avoid Harsh Cleaners that can damage the sealant and weaken the stone

Why Choose Red Travertine Pavers?

Despite their limitations, red travertine pavers remain a popular choice for outdoor use thanks to their warm hues, natural texture, and classic appeal. Their organic imperfections make them a favored material for those seeking rustic elegance.

Key Features:

- Unique reddish tones and organic patterns

- Non-slip texture ideal for walkways and patios

- Natural cooling properties underfoot

- Versatile use in landscapes, gardens, and pool areas

Red Travertine Pavers are a blend of natural artistry and earthy strength. With the right care and handling, they can transform any outdoor space into a Mediterranean-inspired retreat.

Share