Red Travertine

Red Travertine

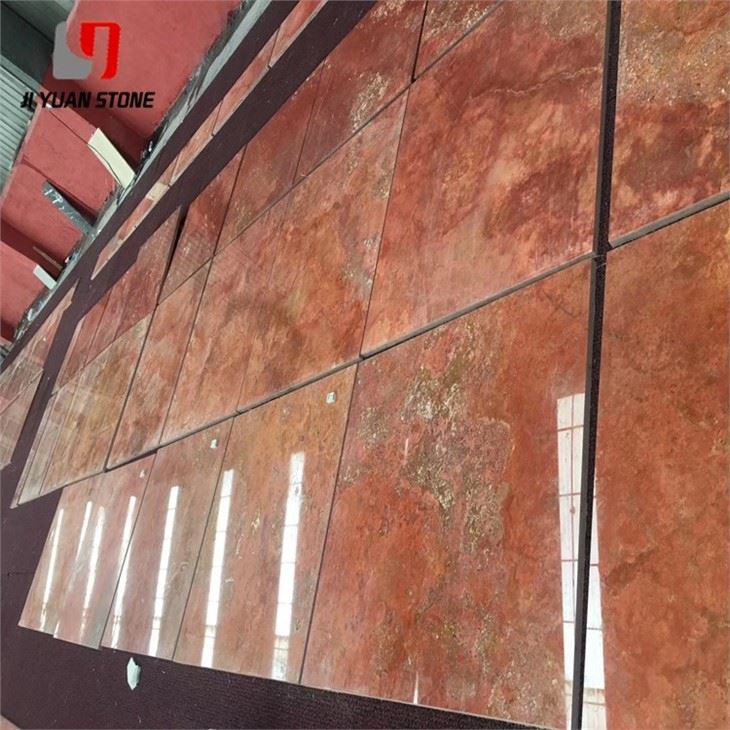

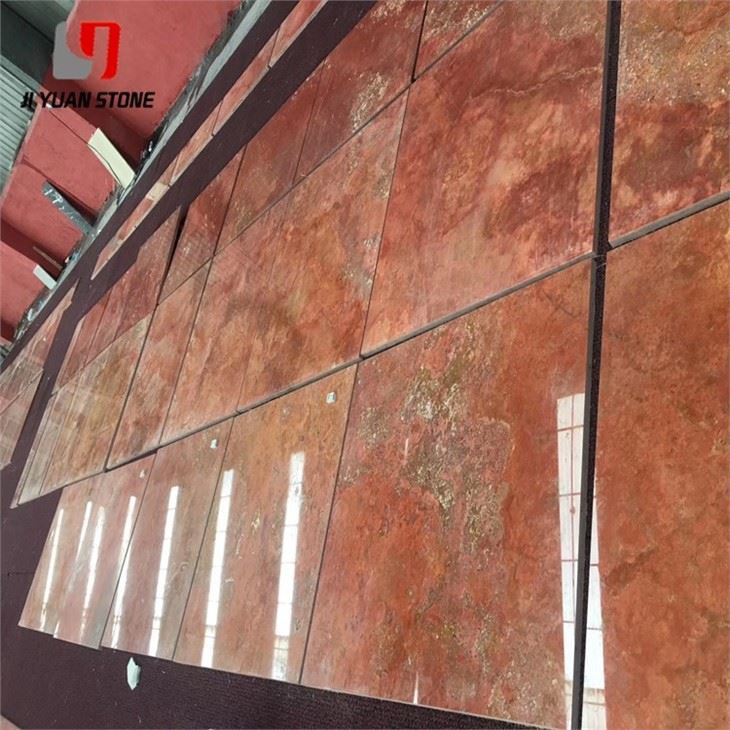

Red Travertine: Natural Elegance with Structural Precision for Architectural Panels

Expertly crafted from Red Travertine, this stunning stone brings a touch of elegance to any space. With its unique color and natural variations, Red Travertine adds a warm and inviting atmosphere. Its durability and low maintenance make it a practical choice for both indoor and outdoor use. Elevate your design with Red Travertine.

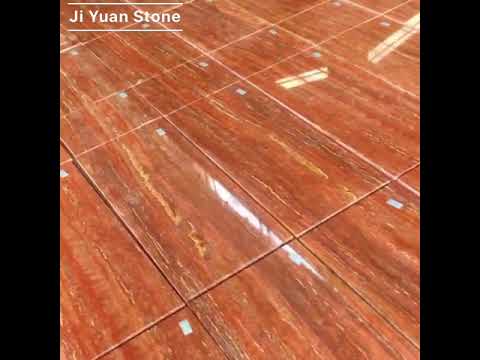

Red travertine is a richly colored natural stone that brings timeless warmth and luxury to any space. Known for its bold red and earthy tones, this stone is frequently used for wall cladding, flooring, façades, and interior accents in both modern and classical architecture.

While red travertine boasts aesthetic appeal and historical charm, it requires precise processing to meet modern building standards. The physical characteristics of the finished stone panels—including thickness, plate size, and waterproofing—play a critical role in its performance, especially in large-scale applications like curtain walls.

Finished Stone Panel Requirements for Red Travertine

To ensure structural integrity and long-term durability, red travertine panels must meet the following basic requirements before installation:

1. Sheet Thickness

Flexural testing reveals that thicker panels, although having lower flexural strength than thinner ones, offer greater overall load-bearing capacity. The minimum required thickness depends on the standard flexural strength value (fk):

- If fk ≥ 8.0 MPa, the minimum panel thickness should be 35mm

- If 4.0 ≤ fk < 8.0 MPa, the minimum panel thickness should be 40mm

The standard value of fk is calculated as the test average minus 1.645 times the standard deviation. If this number is lower than the lowest test result, then the lowest result should be adopted.

Thickness tolerance: +2mm, -0mm. Negative deviations are not permitted for safety reasons.

2. Plate Size

Due to the relatively lower flexural strength of red travertine, the maximum allowable panel size is 1.0 square meter.

- Avoid slender strip stones as they are more prone to cracking during transit and installation.

- The length-to-width conversion ratio should be within 1:2, and must not exceed 1:3.

3. Surface Treatment

Red travertine has high water absorption, which makes waterproof treatment mandatory for its longevity and performance.

- Waterproofing goal: Reduce absorption rate to below 1%.

- For glue-injected board seams, apply waterproofing only on the outer surface.

- For open seams, waterproof all six sides of the stone panel.

- Panels with large or excessive holes must be sealed before use.

Waterproofing should be completed after machining of all grooves and holes, and only on thoroughly cleaned and dried surfaces.

Why Choose Red Travertine?

Red travertine stands out for its:

- Rich, bold hues from natural iron oxide content

- Versatility for both modern and historical designs

- Carvability for custom textures and patterns

- Strong visual impact for exterior façades, lobbies, and decorative walls

Conclusion:

Red travertine is an ideal stone for high-end architectural use—but only when processed and installed according to strict specifications. From sheet thickness and plate size to waterproofing methods, every step ensures durability, beauty, and compliance with modern structural standards.

Choose red travertine for a combination of natural luxury and engineering precision—perfect for timeless designs that last.

Share