1

/

of

14

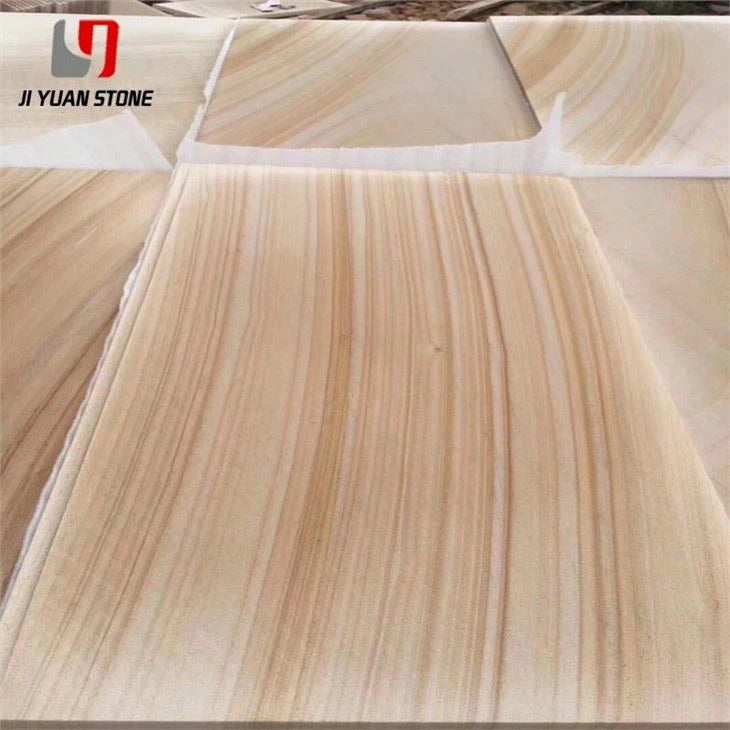

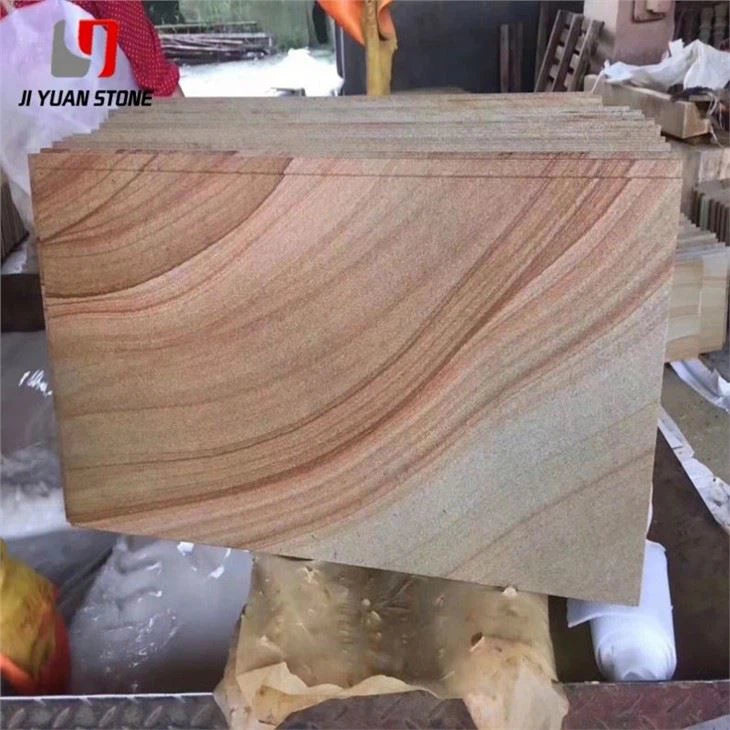

Rainbow Sandstone Honed

Rainbow Sandstone Honed

Discover the stunning beauty of our Rainbow Sandstone Honed, expertly crafted to showcase its natural color palette and unique veining. Enjoy the durability and low maintenance of sandstone while adding a touch of elegance to any space. Perfect for those seeking a sophisticated yet timeless look.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

11.7 Polishing and Crystallization Treatment

Machine Usage Guidelines:

- For a 220 Machine: Move the machine from front to back, ensuring the working plate is close to the wall.

- For a 380 Machine: Use the corner of the machine to get as close as possible to the rainbow sandstone honed surface.

Step-by-Step Process:

- Initial Crystallization:

- Spray K-2 crystal surface treatment agent evenly on the ground.

- Use the steel wool pad attached to the crystal surface treatment machine to rub repeatedly until the rainbow sandstone honed becomes bright and transparent.

- Regularly dust the steel wool pad to maintain efficiency.

- Brightening Treatment:

- Spray K-3 brightener on the ground.

- Use a red scouring pad attached to the crystal surface processor to spread it evenly.

- Continue until the surface reaches a brightness of at least 80 degrees (measured with a gloss meter).

- Final Crystallization for Enhanced Gloss:

- Spray K-2 crystal surface treatment agent again.

- Use a white polishing pad to spread it evenly.

- Continue polishing until the surface gloss reaches approximately 90 degrees.

Share