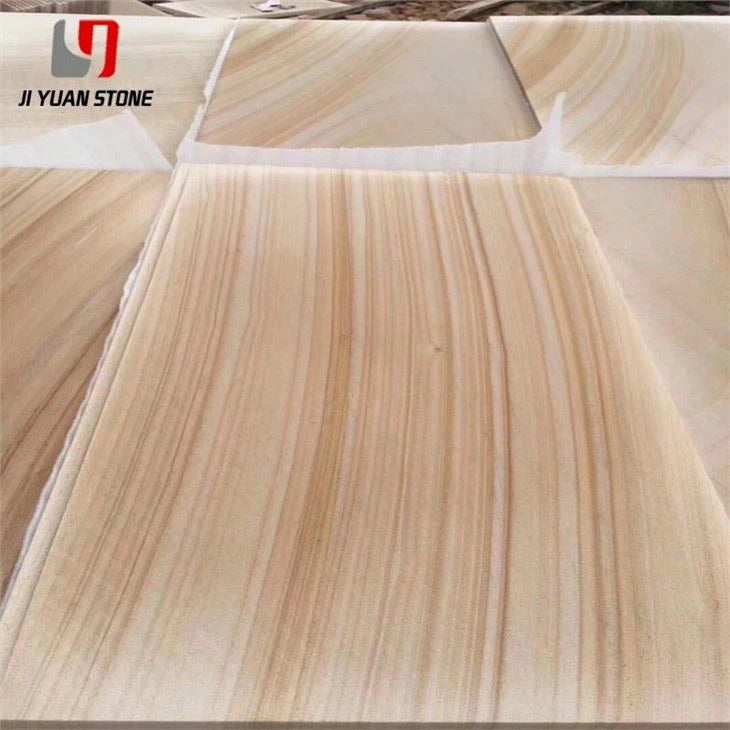

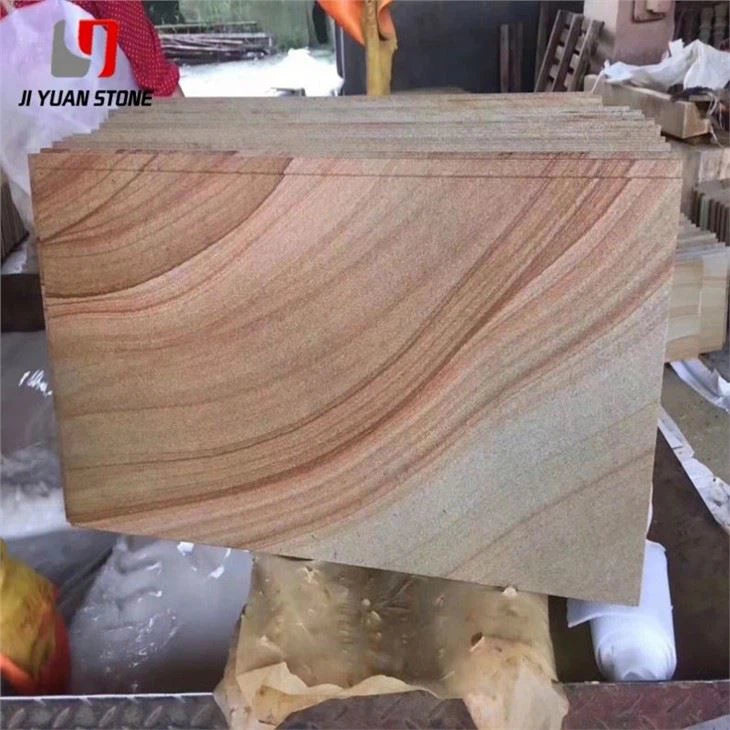

Rainbow Sandstone Floor Tiles

Rainbow Sandstone Floor Tiles

Enhance the aesthetic appeal of your space with our high-quality Rainbow Sandstone Floor Tiles. These durable, natural stone tiles add a touch of elegance while delivering superior strength and longevity. Perfect for both indoor and outdoor use, our Rainbow Sandstone Floor Tiles offer a unique and beautiful flooring solution.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Grinding and Polishing Procedure for Rainbow Sandstone Floor Tiles

11.3 Initial Grinding Treatment (No. 30-60)

Use a 12-head professional rainbow sandstone floor tile leveling machine to smooth out cuts, uneven surfaces, and scratches caused by deformation, paving, processing, and other factors. This step also removes hole contamination and prepares the surface for subsequent treatments like hole repair and fine grinding.

11.4 Coarse Grinding Treatment (No. 36-50)

During this stage, remove excess repair glue from the surface, eliminate wear scars from the initial grinding, and further adjust the flatness of the grinding surface. This process ensures a uniform surface, ready for polishing.

Standard: No visible scratches of size 50! No repair glue left!

11.5 Edge Grinding Treatment (Trimming)

For areas inaccessible to large machines, such as corners and edges affected by initial and middle grinding, use specialized corner equipment with 50-100-200-300 grit water-grinding sheets matched with angle grinders. This step ensures smooth edge transitions and blends with the rest of the floor.

Standard: No cut corners! No burrs or scratches on the edges!

11.6 Fine Grinding Treatment (No. 500-1000-3000)

Once the flatness of the rainbow sandstone floor tiles has been achieved through initial and middle grinding, this step enhances the gloss, preparing the surface for the final polishing process.

Key Procedure Points:

- Starting from grit No. 500, set the grinding disc aside and hold the edge.

- First, polish the four peripheral lines before moving to the center.

- Use the same middle grinding method while ensuring even pressure on the edges.

Share