Prefab Quartz Slabs

Prefab Quartz Slabs

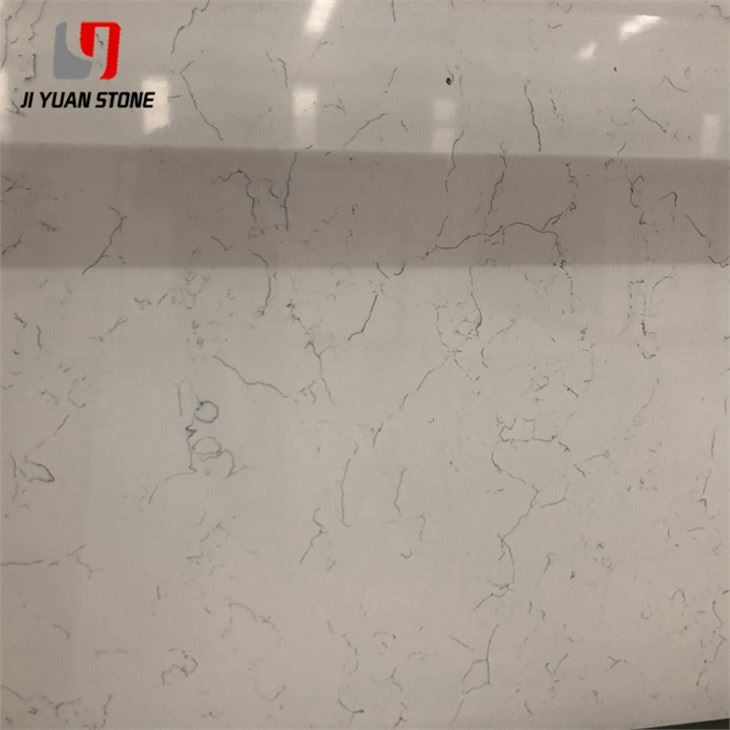

Premium Prefab Quartz Slabs for Durable and Stylish Kitchen Countertops

These high-quality prefab quartz slabs offer a beautiful and durable surface for any kitchen or bathroom. Made from top-grade quartz, these slabs are easy to install and maintain, providing long-lasting beauty and functionality. Enjoy the benefits of a stunning, low-maintenance countertop with prefab quartz slabs.

Prefab quartz slabs are quickly becoming the top choice for homeowners and interior designers who seek high performance, longevity, and visual appeal in their kitchen surfaces. Engineered using high-purity quartz sand and compressed under vacuum with advanced vibration technology, these quartz slabs offer exceptional hardness and durability—perfect for the most demanding kitchen environments.

Why Choose Prefab Quartz Slabs?

Our prefab quartz slabs are designed to meet the highest standards of quality and practicality. They come with a range of product features that make them ideal for modern kitchens:

Product Characteristics:

- Scratch Resistant – Knives won’t leave a mark.

- Stain Resistant – Easily resists coffee, fruit juice, tea, and more.

- Hygienic Surface – Inhibits bacteria; food can be prepared directly on the surface.

- Chemical Resistant – Withstands acids and alkalis like vinegar and lemon juice.

- Maintenance-Free – No sealing required; simple daily cleaning keeps it pristine.

- Highly Durable – Long-lasting surface that retains its new look for decades.

- Aesthetic Variety – Available in white, black, beige, red, pink, and more to suit every kitchen style.

- Smart Choice for Kitchen Remodeling

The kitchen countertop is the most used and most visible surface in a home, making the right material selection crucial. Prefab quartz slabs stand out for their durability, hygiene, and stunning designs. However, like any material, proper handling and installation are key to preserving its strength and look.

Important Notes for Processing & Installation:

When cutting, splicing, or creating holes in the quartz slab, follow these key precautions to avoid cracking and ensure a seamless finish:

- Check for Color Matching: Ensure both slabs have consistent color to avoid mismatched countertops.

- Avoid Edge Chipping: Prevent cracking by avoiding sharp impacts and edge chipping during cutting.

- Use Rounded Corners: When cutting stovetop or sink holes, round corners are preferred over right angles to prevent stress points.

- Seamless Splicing: Use factory-recommended resin glue instead of marble glue to ensure smooth, seamless joints.

- Proper Polishing: Splicing seams must be polished to match the slab’s surface shine. Poor polishing can lead to dirt buildup and hard-to-clean surfaces.

To minimize on-site risks, we recommend factory-cut openings and professional installation using industry best practices.

Conclusion:

Invest in high-quality prefab quartz slabs that combine function, form, and endurance. Whether you're renovating a home or outfitting a commercial kitchen, our prefab quartz slabs offer an ideal balance of beauty, strength, and hygiene—making them a smart, long-lasting choice.

Share