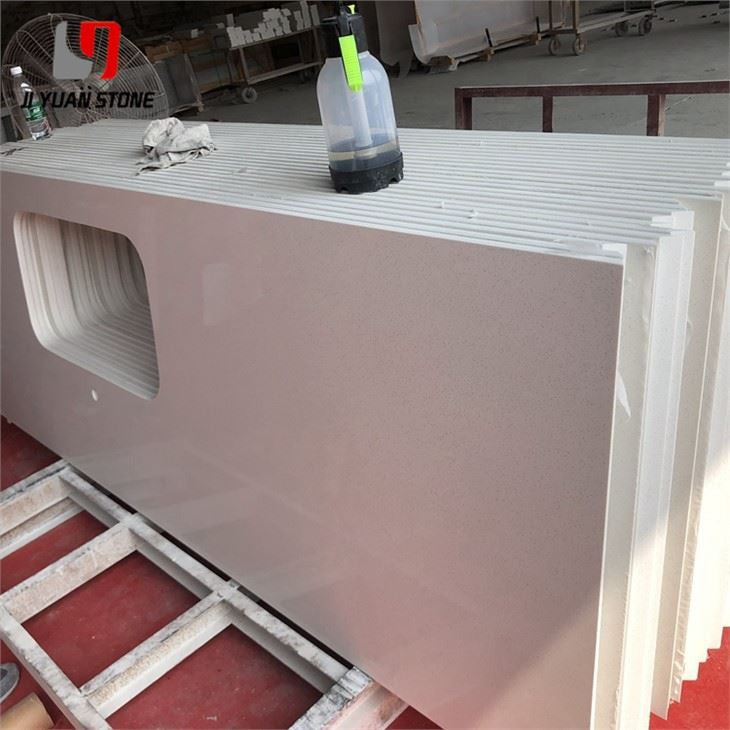

Pre Cut Quartz Vanity Tops

Pre Cut Quartz Vanity Tops

Pre Cut Quartz Vanity Tops – Strong, Stylish & Reliable

These Pre Cut Quartz Vanity Tops offer the perfect combination of durability and style. Made from high-quality quartz material, they are resistant to scratches, stains, and heat damage. Each top is precisely cut to fit perfectly, providing a seamless and elegant look to your bathroom.

| Feature | Details |

|---|---|

| Material | 93% Nature Quartz |

| Slab Size | 1600X3200 or cut to size |

| Thickness | 20mm,30mm |

| Surface | 100% full polished |

| Color range | Calacatta, marble looks, carrara, basic colors, blendid colors |

| Slabs packing | 105 slabs 2cm per 20ft container and 70 salbs 3cm per 20ft container |

| Applications | Kitchen countertop, bathroom vanity tops, benchtops, kitchen island, bar countertops, residential and commercial projects. |

| Delivery time | Within 20 days after get deposit |

Pre cut quartz vanity tops are becoming the top choice for homeowners, designers, and builders worldwide. Known for their exceptional durability, stain resistance, and modern aesthetics, these vanity tops are perfect for kitchens, bathrooms, and even commercial spaces. With up to 90% natural quartz content, they combine strength and beauty—making them a superior alternative to both traditional stone and artificial materials.

🌍 Global Market Trends

The popularity of pre cut quartz vanity tops is rapidly growing across the globe:

- 🇦🇺 Australia accounts for 35% of global quartz consumption

- 🇺🇸 United States holds 22%

- 🇨🇦 Canada follows with 14%

In addition to these established markets, demand in Europe, the Middle East, Southeast Asia, Singapore, Malaysia, Thailand, Vietnam, Japan, South Korea, and Hong Kong has surged. Quartz is steadily replacing traditional cabinet materials and being used in ground decoration and interior design applications, highlighting its strong future growth.

🇨🇳 Domestic Market & Production

In China, pre cut quartz vanity tops are witnessing significant expansion. Many manufacturers are shifting from ceramic tiles, microcrystalline stone, and natural stone production to quartz stone due to its higher profitability.

- Production hubs: Guangdong, Fujian, Shanghai, and Jiangsu

- Growth driver: Restrictions on natural ore mining, pushing demand for engineered quartz

- Result: A thriving domestic artificial stone industry with world-class quartz stone output

⚙️ Manufacturing Process & Material Strength

The manufacturing process of pre cut quartz vanity tops is similar to artificial granite but with key enhancements:

- ✅ Up to 90% quartz sand & powder for superior strength

- ✅ Mohs hardness of 7 – excellent scratch resistance

- ✅ Non-porous surface – prevents stains, bacteria, and water absorption

- ✅ Heat & fire resistance – perfect for kitchens

Advanced production lines use vacuum vibration, pressure casting, and medium-temperature baking, creating a dense, polished surface with minimal resin. The result is high-quality quartz vanity tops that rival imported Italian standards.

🔹 Product Advantages

✔ High scratch resistance – withstands daily wear and tear

✔ Non-porous & stain-resistant – hygienic and easy to clean

✔ Fire-resistant & heat-resistant – safe for bathroom & kitchen use

✔ Long-lasting shine – maintains elegance for years

✔ Pre cut for convenience – ready-to-install design

🔹 Why Choose Pre Cut Quartz Vanity Tops?

As natural stone resources decline, artificial quartz is becoming the preferred material for countertops, vanity tops, and interior design. While some lower-quality products may develop bubbles or deform, advanced engineered quartz guarantees a solid, polished, and durable finish that meets international quality standards.

✅ Conclusion

Pre cut quartz vanity tops are more than just a stylish upgrade—they are the future of countertops. With their unmatched durability, stain resistance, and global popularity, they are set to replace both natural and artificial stones in homes and commercial spaces.

Upgrade your kitchen or bathroom with pre cut quartz vanity tops and enjoy long-lasting beauty, strength, and functionality.

Share