Paving Sandstone Slabs

Paving Sandstone Slabs

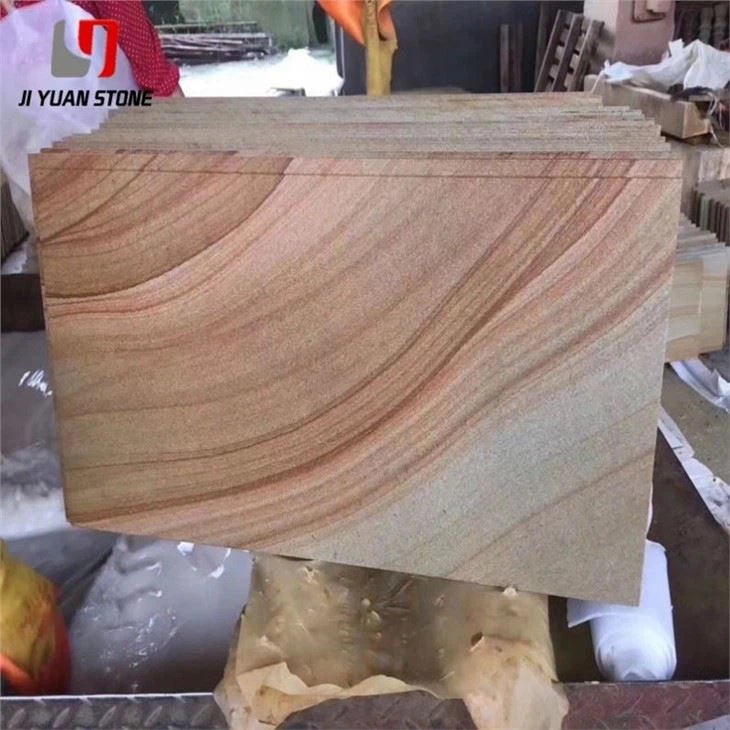

Paving Sandstone Slabs – Premium Quality for Outdoor Projects

Paving Sandstone Slabs are a versatile and durable option for any outdoor paving project. Made from high-quality sandstone, these slabs are resistant to weathering and can withstand heavy foot traffic. Their natural texture and color add a touch of elegance to any outdoor space.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Elevate your landscape and architectural design with our high-performance paving sandstone slabs. Renowned for their natural elegance, strength, and weather resistance, these slabs are ideal for pathways, patios, courtyards, and high-traffic public spaces. Crafted from durable sandstone, they offer both aesthetic appeal and long-term functionality.

Comprehensive Management of Paving Sandstone Slabs Construction Stage

Managing paving sandstone slabs efficiently is crucial to project success. Merely placing orders and receiving materials on-site does not guarantee smooth progress or cost control. A well-structured management system after material arrival is essential to avoid losses and delays.

1. On-Site Acceptance of Paving Sandstone Slabs

Upon delivery, conduct a thorough inspection against the original material order form. Carefully check:

- Variety

- Specifications

- Quantity

- Processing quality

- Surface condition

Only materials that meet design and order standards should be approved for use. Once verified, stack materials in an organized manner—centralized or by usage area—and label them clearly using spray paint or sticky notes for easy identification.

⚠️ Reject any unqualified materials immediately to prevent installation issues or costly replacements later.

2. Secondary Transfer of Construction Site Materials

Due to spatial constraints or packaging limitations, many sandstone slabs cannot be placed directly in their final positions and may require secondary transfers. These movements increase the risk of breakage, material loss, and time consumption. Minimize losses by adopting the following strategies:

- Centralized Transfer: Use machinery to efficiently move materials according to the construction plan. Maintain close communication between workers and operators to avoid mishandling.

- Packaging Adjustment: If the original packaging is weak or damaged, reinforce it before transfer to protect the slabs.

- Reduce Handling: Ideally, deliver slabs to their final position in a single transfer to limit potential damage.

By optimizing movement and reinforcing packaging, you can protect your sandstone slabs and reduce costs significantly.

Why Choose Our Sandstone Slabs?

- ✅ Naturally non-slip and weather-resistant

- ✅ Available in custom sizes and surface finishes

- ✅ Ideal for gardens, walkways, patios, and commercial landscapes

- ✅ Easy to install, low maintenance

- ✅ Expert-approved for construction efficiency

Applications

- Outdoor patios and walkways

- Residential courtyards

- Hotel and resort landscapes

- Public parks and plazas

- Architectural paving projects

Conclusion

At Purchasestones, we combine premium materials with expert guidance to help you manage every phase of your sandstone paving project. Our paving sandstone slabs are crafted for strength, beauty, and performance. When paired with proper site management, they ensure your project is completed on time, on budget, and to the highest standards.

Share