Paving Sandstone

Paving Sandstone

Paving Sandstone – Durable, Elegant, and Built for Precision Construction

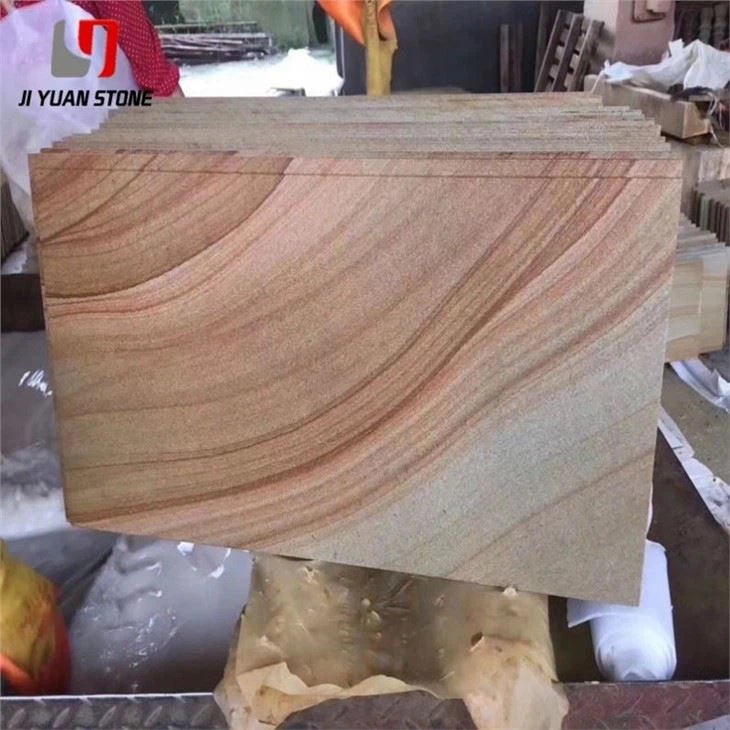

Paving Sandstone is a durable and versatile material, making it ideal for outdoor surfaces. With its compact and slip-resistant texture, it provides a safe and stable foundation for any type of pavement. Its natural composition also offers a unique and attractive aesthetic to enhance the overall look of your space.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Our premium paving sandstone is the ideal choice for both residential and commercial landscaping projects. Known for its natural beauty, high durability, and versatile design, sandstone paving enhances the aesthetic and structural value of outdoor spaces such as walkways, patios, courtyards, and public plazas.

Management of Paving Sandstone on Construction Sites

Proper on-site management ensures a successful paving project. To maintain quality and minimize waste, every stage of handling and installation should be carefully monitored.

Cutting and Material Handling

- Cutting should be strictly controlled on-site to prevent excess waste.

- After cutting, remaining materials must be centrally stacked using wooden pallets for easier transportation.

- This organized system ensures better material recovery and site cleanliness.

Worker Instructions and Precautions

Before installation, conduct a technical briefing with all construction workers to ensure proper handling techniques:

- Avoid direct hammering on fragile or smooth paving sandstone.

- Instead, use wooden boards to cushion impact, preventing cracks and surface scratches.

- Emphasize the importance of preserving the stone’s appearance and preventing damage during installation.

Material Management and Utilization

- All damaged materials should be collected and repurposed—especially useful for corner finishes or smaller detail work.

- Maintain a dedicated damage log to track material usage and minimize losses.

- Ensure accurate documentation of the completed paving area, matched with delivery schedules and statistical analysis.

Project and Cost Management

Managing paving sandstone is not just about aesthetics—cost control is crucial. Key practices include:

- Matching project output with material availability and delivery timelines.

- Ensuring that the landscape design aligns with the client's vision and quality expectations.

- Avoiding unnecessary waste and delays to maximize profit margins.

Holistic Construction Site Management

Stone material management is just one part of comprehensive project oversight. To ensure timely delivery and high-quality results, every phase of the construction process—from planning and procurement to cutting, paving, and quality inspection—must be aligned with industry best practices.

Why Choose Our Paving Sandstone?

✅ Weather-resistant and long-lasting for outdoor use

✅ Naturally slip-resistant surface texture

✅ Available in custom sizes and finishes

✅ Easy to install and maintain

✅ Perfect for gardens, patios, pool decks, and pathways

Applications

- Landscape architecture

- Commercial and residential walkways

- Driveways and courtyards

- Garden paths and patios

- Public spaces and plazas

Conclusion

When it comes to high-performance paving materials, sandstone stands out for its natural beauty, strength, and adaptability. With professional handling and organized site management, our sandstone paving solutions help you achieve both visual excellence and cost efficiency.

Transform your outdoor spaces with Purchasestones’ paving sandstone—engineered for beauty, built for longevity.

Share