Paver Sandstone

Paver Sandstone

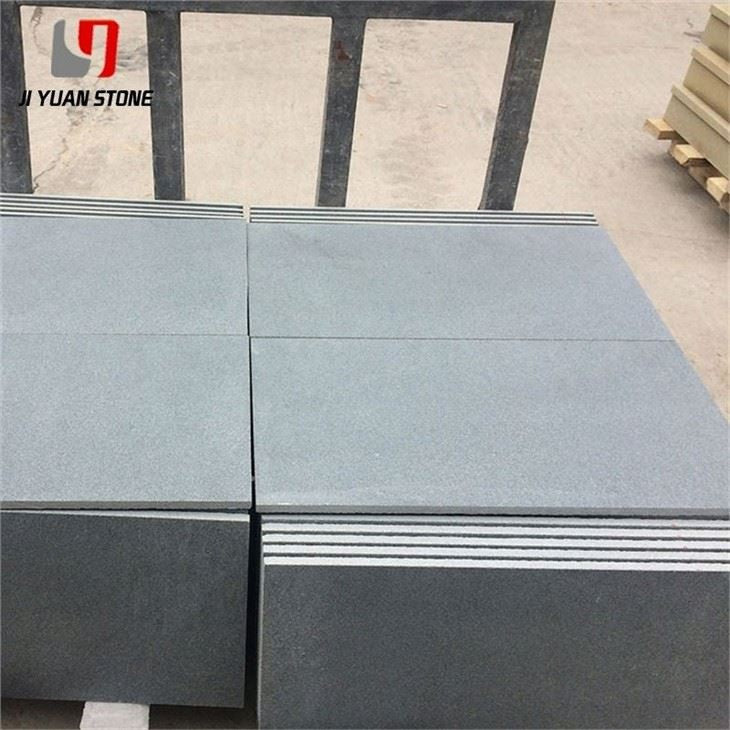

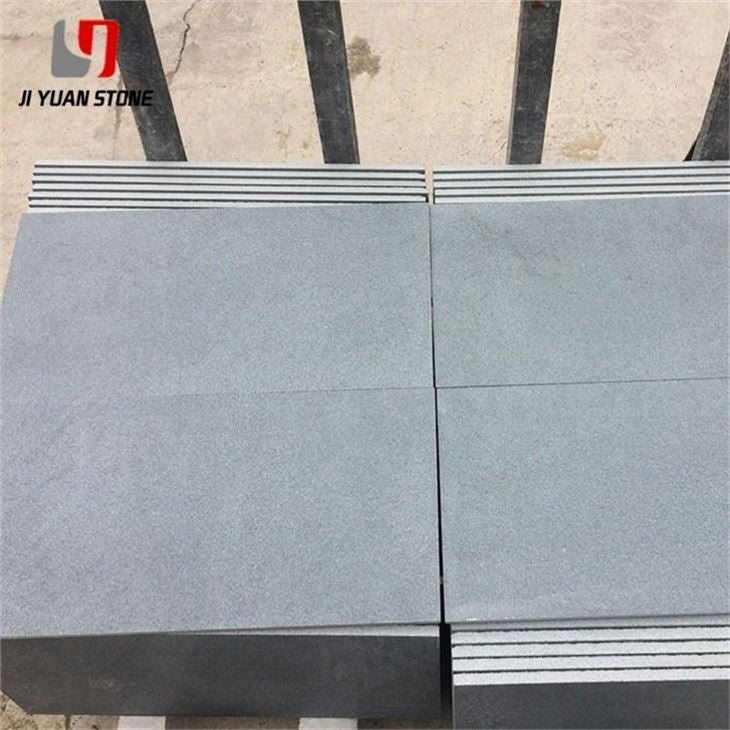

Paver Sandstone – Durable Natural Stone with Expert Seam Sealing for Outdoor Paving

Paver Sandstone is a high-quality material that provides durability and strength for all your outdoor paving needs. Its natural texture and color give a timeless and elegant look to any space. With Paver Sandstone, you can transform your outdoor area into a beautiful and functional oasis.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

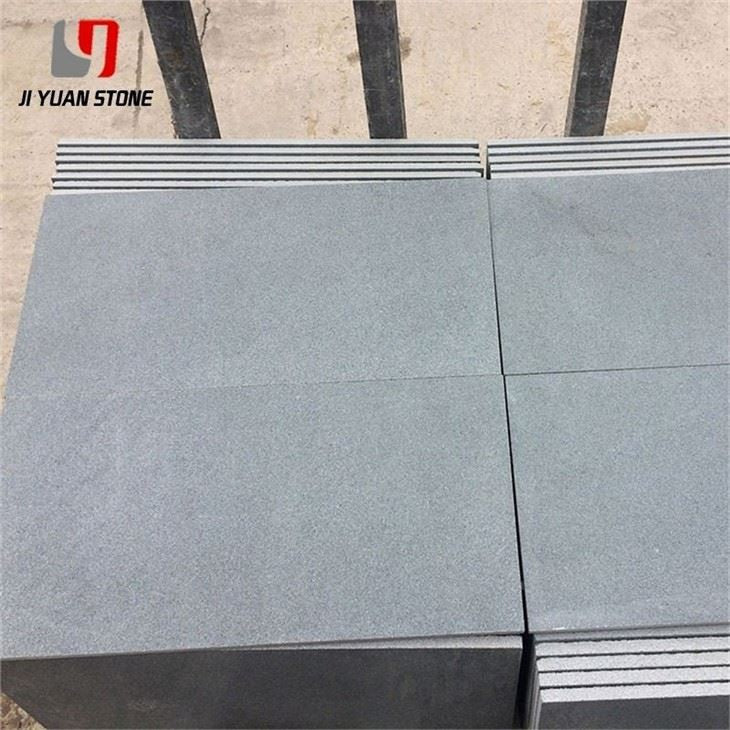

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

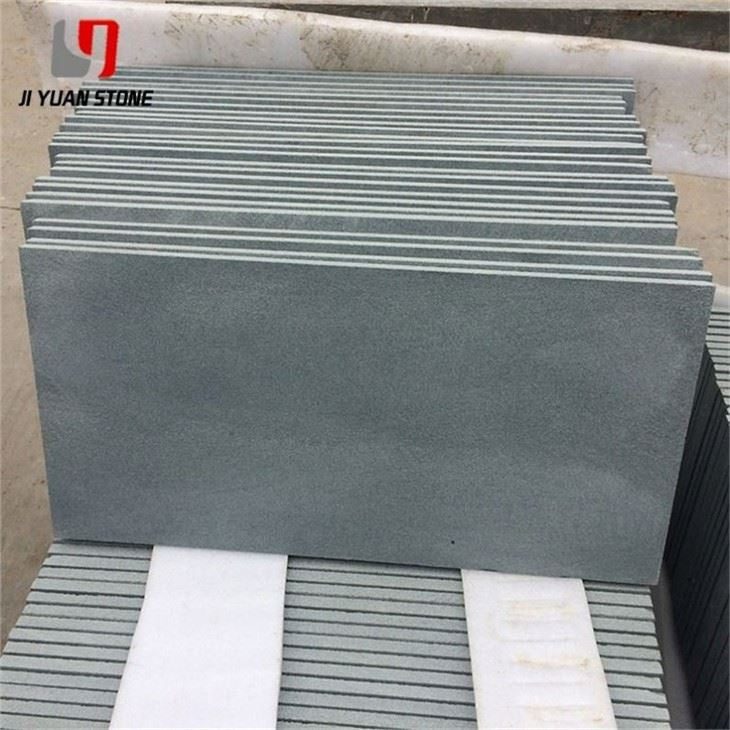

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

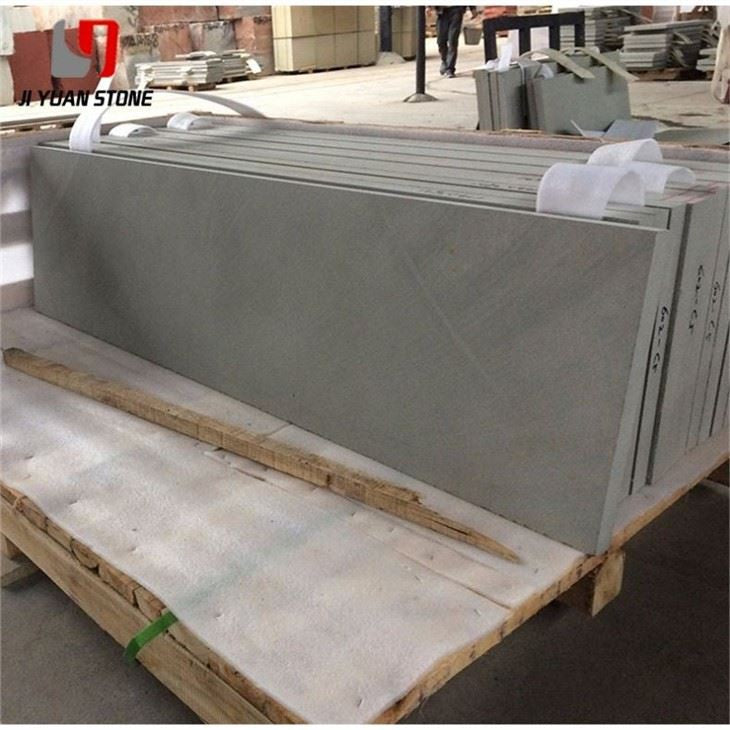

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Paver sandstone is an ideal choice for outdoor paving applications, combining natural beauty with exceptional durability. To maintain the longevity and seamless appearance of sandstone pavers, proper surface preparation and professional seam sealing techniques are essential.

🔧 Essential Guidelines for Paver Sandstone Joint Sealing

① Surface Preparation:

Before gluing, thoroughly clean the joints of paver sandstone slabs by removing dust, water, oil, and other contaminants. Keeping the joints clean and dry is crucial for optimal bonding quality.

② Foam Rod Insertion:

Use a scraper with a convex head to insert a foam rod into the joint before glue injection. The foam rod’s diameter should be slightly larger than the glue seam width to ensure complete filling and firm adhesion.

③ Surface Protection:

Apply paper tape along both sides of the joint gap to protect the stone surface from excess glue during the sealing process.

④ Glue Injection Best Practices:

The caulking glue used is a specialized silicone sealant designed for paver sandstone slabs. Glue injection temperature should range between 5°C and 40°C. Inject glue continuously to avoid gaps. Remove any glue spills immediately using detergent. The glue thickness should be half the seam width but no less than 4mm to prevent joint failure under stress.

⑤ Seam Finishing:

After glue application, use a scraper to shape the seam into a concave finish before the surface layer cures. Remove the protective paper tape promptly and avoid gluing during rainy or windy conditions.

⑥ Final Cleaning:

Once the glue is set, clean both sides of the joint with a clean cotton or lint-free white cloth soaked in a special solvent or oxalic acid. Avoid dipping the cloth directly into the solvent to protect the finished surface.

🌿 Why Choose Paver Sandstone?

- Natural Durability: Resistant to weathering, ideal for outdoor use.

- Professional Seam Sealing: Prevents water infiltration and joint damage.

- Aesthetic Appeal: Clean, precise joints enhance overall paving beauty.

- Easy Maintenance: Proper installation ensures long-lasting performance.

Ensure your outdoor paving projects stand the test of time with our high-quality paver sandstone and industry-leading seam sealing techniques. Combining natural elegance with expert craftsmanship, our sandstone paving solutions provide both style and durability.

Share