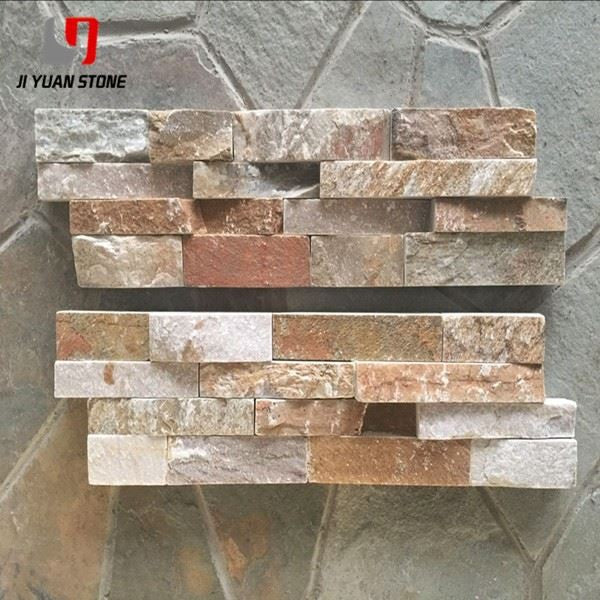

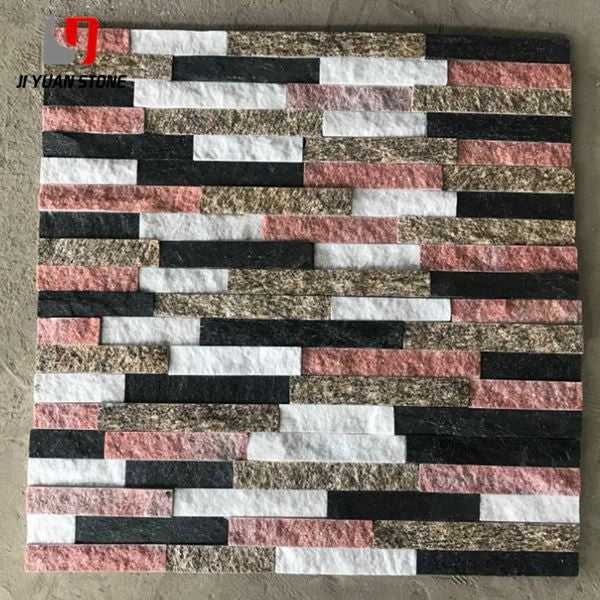

Outdoor Stone Wall Panels

Outdoor Stone Wall Panels

Natural Outdoor Stone Wall Panels – Precision, Durability & Beauty

Enhance your outdoor space with our durable and stylish stone wall panels. Made to withstand the elements, these panels add texture and depth to any surface. Easy to install, these panels are a cost-effective way to elevate your outdoor design and create a stunning focal point.

| Feature | Details |

|---|---|

| Product | Outdoor Stone Wall Panels |

| Surface | Honed,Split face,Natural Cleft,Machine Cut, etc |

| Colour | Many colors for choice |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, stairs, steps, wall panel, flooring, veneers, slabs, coping tiles, bathtub etc |

| Thickness | 0.8-1.2cm,1-1.5cm,1-2cm,1.5-2.5cm,2.5-3.5cm etc |

| Another item name | Slate stone veneer, natural wall panel, stone ledge veneer, slate wall cladding, ledgestone, stacked stone, etc. |

| Material | 100% natural slate, quartzite |

| Regular size |

|

| Processing mode | Hand split, stick with glue or cement , Machine cut to size. picked |

| Shape | Rectangle, Square, Z-shape, S-shape, Corner |

| Packing | Carton box, environment-friendly pallets and strong fumigated wooden crate suitable for long distance delivery |

| Application | Suitable for Interior & exterior wall decoration, such as house, garden, park, villa, plaza and office,etc |

| Sample | Free sample |

| Delivery time | Within 15 days |

| Payment term | T/T(30% deposit), L/C and other payment term after negotiation |

| MOQ | 100 M2 |

| Main market | Europe, The Middle East, North America, Australia, Africa and Southeast Asia |

Upgrade your building exteriors and landscaping designs with our natural outdoor stone wall panels, meticulously processed for durability and aesthetic excellence. Crafted from high-quality natural stone, these panels offer a rugged yet elegant facade solution that blends seamlessly with any outdoor environment.

🛠️ Processing Order for Natural Outdoor Stone Wall Panels

Producing flawless stone wall panels requires strict adherence to precise dimensions and expert craftsmanship. Here are the key factors considered during processing:

1. Key Dimensions in Surface Processing

- t1 – Depth Dimension: Measures the vertical difference from the highest to lowest points on the natural stone surface, ensuring authentic texture.

- t – Thickness: Refers to the final thickness of the processed stone panel, critical for strength and installation.

- B – Height (or Width): Dictates the panel size, affecting the machining allowance and structural fit.

2. Parting Process

This stage involves cutting opened blanks into specific sizes according to the order requirements. Key benefits include:

- No machining allowance needed for length and height directions.

- Ensures high accuracy in final panel dimensions and shapes.

3. Machine Debugging

Before mass processing, machines are carefully calibrated to optimize production quality:

- Set processing parameters based on machine capabilities.

- Adjust rivet height and ensure workpiece fixture stability.

- Confirm rivet alignment and security to prevent defects.

4. Trial Splitting Process

Trial splits are conducted before batch production to monitor quality and minimize material waste. Quality checks focus on:

- Uniformity of natural surface bumps and grooves.

- Controlling height variation to under 30mm for consistency.

- Ensuring smooth surface without large pits or protrusions.

- Maintaining evenness on all four side sections.

Trial splitting helps identify and resolve potential issues early, enhancing production efficiency and maximizing profitability.

🪨 Why Choose Our Natural Stone Wall Panels?

- Superior Natural Texture: Each panel features genuine stone depth and surface variation.

- Durability: Resistant to weathering, erosion, and daily wear.

- Precision Engineering: Manufactured with exacting standards for seamless installation.

- Aesthetic Versatility: Perfect for facades, garden walls, columns, and exterior decor.

🌟 About Xiamen Ji Yuan Stone

Xiamen Ji Yuan Stone is a trusted professional supplier of natural stone products with over 10 years of expertise in stone supply chain development. We collaborate with over 30 quarries across China, covering granite, marble, sandstone, slate, and basalt. With our own 2 quarries and 3 production bases equipped with advanced machinery and skilled professionals, we ensure top-quality products and customer satisfaction.

Elevate your architectural projects with our natural outdoor stone wall panels — where precision processing meets natural beauty. Contact us today for custom solutions and reliable stone cladding supply.

Share