Outdoor Stone Veneer

Outdoor Stone Veneer

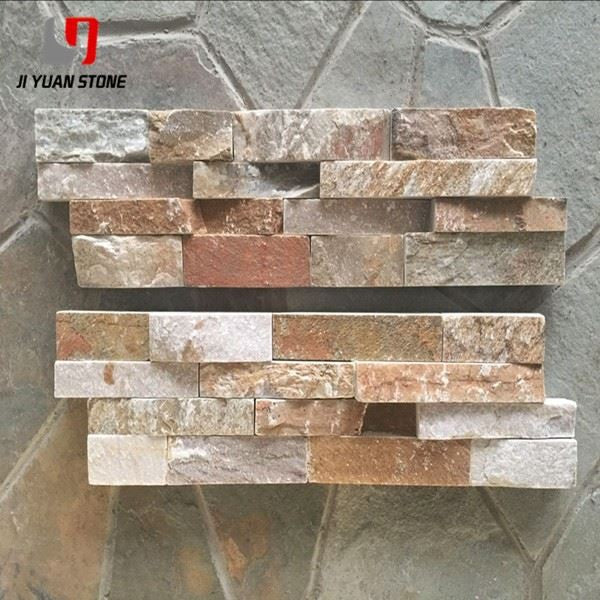

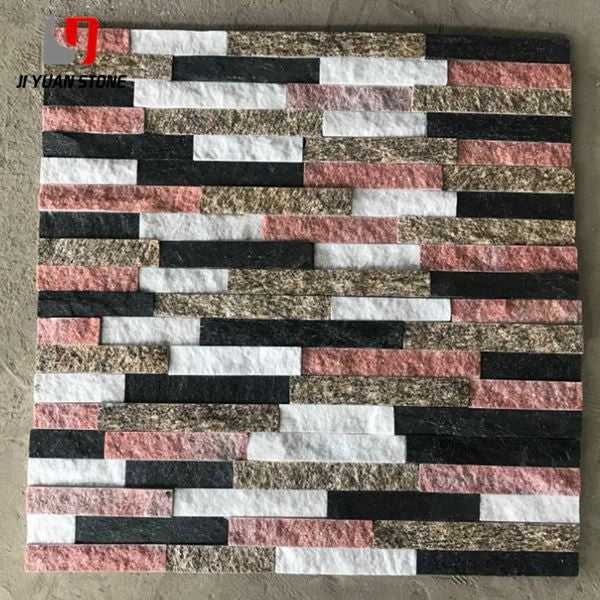

Natural Outdoor Stone Veneer – Authentic Texture & Superior Craftsmanship

This outdoor stone veneer is expertly crafted to enhance the exterior of your home. With its durable construction and natural look, it adds both beauty and functionality to any outdoor space. Upgrade your home's curb appeal and value with this high-quality product.

| Feature | Details |

|---|---|

| Product | Outdoor Stone Veneer |

| Material | Natural stone,like Granite,Porphyry,Basalt,Sandstone, Slate,Andersite,limestone,Lava,Marble,Pebble etc. |

| Surface finish | Polished,Flamed,Bush-Hammered,Groove,Natural Split,Honed,etc. |

| Colour | Grey, Dark Grey, Yellow, Brown, Red, Green, Black, White etc. |

| Size | As your requirements |

| Thickness | 0.8-1.2cm,1-1.5cm,1-2cm,1.5-2.5cm,2.5-3.5cm etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, stairs, steps, wall panel, flooring, veneers, slabs, coping tiles, bathtub etc |

| Quality |

1) High-quality requirements; 2)QC follow from blcok cutting to packng; 3)Accurate cutting and fabrication as per order; 4)Color Variation: Almost Same; 5)Thickness tolerance: -1+2 mm. |

| Usage | Widely used in wall, gardening, landscape, building, patio,driveway, walkway etc. |

| Package | In fumigated strongly wooden crate, Inner packing by foamed plastics. |

| Delivery time | 1-20days ONE container,21-40days TWO-THREE containers. |

Enhance your exterior walls and landscaping with our natural outdoor stone veneer, offering authentic textures and rugged beauty. Manufactured with a blend of traditional mining and advanced processing methods, our stone veneers deliver unmatched durability and aesthetic appeal, ideal for both residential and commercial projects.

🪨 Sources and Processing of Natural Surface Products

Natural surface products come from two primary sources:

1. Mining Process

Stone veneers feature natural surfaces formed during the extraction of large stone blocks directly from quarries. Early mining techniques relied on drilling holes and splitting stone blocks manually using anvils, which often resulted in surfaces with holes and reduced visual appeal.

2. Factory Processing

Modern processing techniques enhance and refine natural surfaces through controlled industrial methods, producing consistent, high-quality stone veneers.

⚒️ Modern Mining Techniques for Outdoor Stone Veneer

Thanks to advancements in mining technology, manual splitting has been largely replaced by highly efficient methods, including:

- Splitting Machines: Mechanized devices that apply precise pressure to split stones cleanly.

- Airbag Separation: Innovative airbag tools that apply uniform force for smooth surface separation.

These modern methods minimize damage, improve surface quality, and increase production efficiency.

🛠️ Surface Processing Technology: Mine Splitting Machine Process

Our natural stone veneer surfaces are crafted using a detailed multi-step process:

1 . Work Surface Cleaning

Clear all debris and obstacles to ensure a clean and safe workspace.

2 . Drilling

Drill holes at specified intervals and depths to define the size of stone blocks to be split.

3 . Installing Wedges and Wedge Blocks

Insert wedges into drilled holes to prepare for splitting.

4 . Starting the Rock Splitter (Pressurization)

A hydraulic splitter applies strong pressure via wedges, splitting the stone within minutes.

5 . Adding Wedges

Thicker wedges are gradually added as cracks develop to complete the separation of stone blocks.

🌟 Why Choose Our Natural Outdoor Stone Veneer?

- Authentic Natural Texture: Surfaces retain the rugged, unique characteristics of quarried stone.

- Durability: Resistant to weathering, ideal for outdoor applications.

- Advanced Processing: Modern mining and splitting methods ensure quality and efficiency.

- Versatility: Suitable for exterior cladding, landscaping, garden walls, and more.

🔹 About Xiamen Ji Yuan Stone

With over 10 years of expertise, Xiamen Ji Yuan Stone is a trusted supplier of natural stone products. We collaborate with more than 30 quarries across China, covering granite, marble, sandstone, slate, and basalt. Our own 2 quarries and 3 production bases are equipped with state-of-the-art machinery and a skilled professional team, ensuring every product meets the highest standards of quality and craftsmanship.

Elevate your outdoor spaces with our natural outdoor stone veneer — combining tradition, technology, and timeless natural beauty. Contact us to learn more or request a quote today.

Share