Outdoor Stone Cladding

Outdoor Stone Cladding

Outdoor Stone Cladding – Natural Beauty for Exterior Elegance

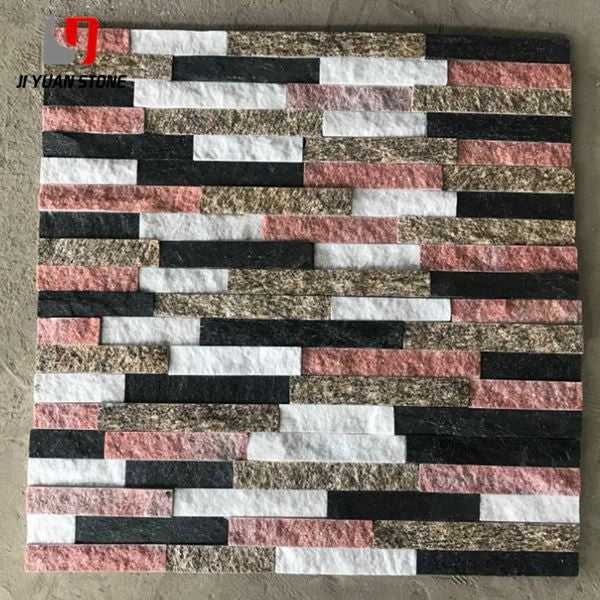

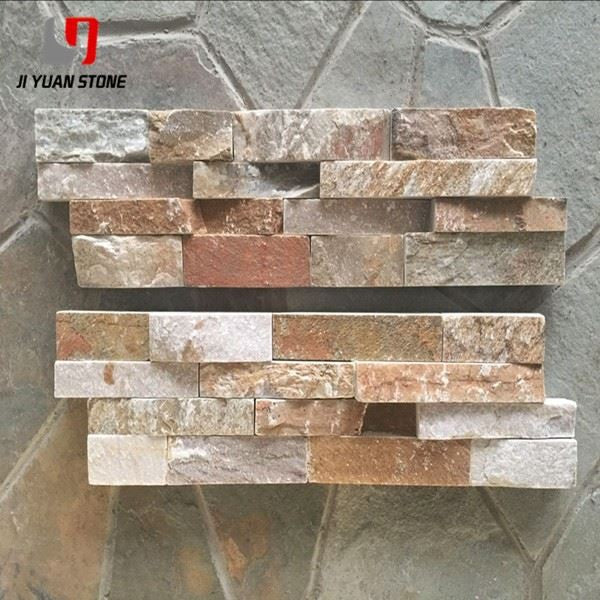

Enhance the beauty of your outdoor spaces with our durable Stone Cladding. Made specifically for outdoor use, it will withstand all weather conditions and adds a touch of elegance to any exterior surface. Bring the natural look of stone to your outdoor living areas with ease.

| Feature | Details |

|---|---|

| Product | Outdoor Stone Cladding |

| Surface | Honed,Split,Natural Cleft,Machine Cut, etc |

| Colour | Many colors for choice |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, stairs, steps, wall panel, flooring, veneers, slabs, coping tiles, bathtub etc |

| Thickness | 0.8-1.2cm,1-1.5cm,1-2cm,1.5-2.5cm,2.5-3.5cm etc |

Enhance the durability and visual appeal of your building's exterior with natural outdoor stone cladding. Known for its strength, versatility, and striking appearance, this premium cladding solution transforms facades, garden walls, columns, and more into timeless works of architectural design.

🧱 What Is Outdoor Stone Cladding?

Outdoor stone cladding is a technique that involves covering exterior walls with natural stone panels, offering both protection and aesthetic enhancement. These cladding stones not only resist harsh weather conditions but also create a natural, luxurious facade.

With stunning textures and color variations, stone cladding panels deliver a warm and authentic look, ideal for:

- Residential facades

- Commercial buildings

- Garden and courtyard walls

- Landscape architecture

🛠️ Processing Natural Outdoor Stone Cladding Surfaces

1. Challenges in Stone Processing

One of the primary concerns during cladding stone processing is material fracture, especially in brittle stones like marble. Large surface areas are more prone to breakage, making it essential to:

- Limit oversized panels

- Apply reinforcement techniques

- Adjust cladding sizes for durability and efficiency

2. Manual Processing Technology

The creation of natural outdoor stone cladding involves careful manual craftsmanship:

Key Steps in Manual Splitting:

- Material Selection

- Blank Opening

- Piece Separation

- Line Drawing

- Splitting and Surface Treatment

- Final Inspection

- Warehouse Storage

3. Precision Line Drawing – A Crucial Step

Line drawing ensures consistent thickness and accurate splicing, preventing misalignment.

Required Tools:

- Steel ruler

- Woodworking pen or sketch pen

Step-by-Step Line Drawing:

1 . Choose the thinnest side as the baseline

2 . Mark consistent horizontal reference points

3 . Connect marks using a ruler

4 . Repeat on all sides to ensure accuracy before splitting

This meticulous process guarantees the production of uniform, interlocking stone panels that enhance wall stability and aesthetics.

🪨 Natural Stone Advantages

- Durability: Withstands weather extremes, erosion, and time

- Low Maintenance: Resistant to cracking and fading

- Thermal Insulation: Helps regulate internal temperatures

- Eco-Friendly: Naturally sourced and free from synthetic chemicals

- Aesthetic Versatility: Available in various finishes and colors

🌍 About the Supplier – Xiamen Ji Yuan Stone

Xiamen Ji Yuan Stone is a leading manufacturer and exporter of natural stone products. With over 10 years of experience, we’ve established:

- Partnerships in 30+ quarries across China

- Ownership of 2 quarries and 3 production bases

- Advanced stone-processing machinery

- A skilled, experienced team of workers, inspectors, and managers

We specialize in materials such as granite, marble, sandstone, slate, and basalt, and offer both standard and custom stone solutions.

🏡 Transform Your Space with Natural Outdoor Cladding

Whether you're designing a modern exterior or adding rustic charm to a traditional build, our natural outdoor stone cladding provides the perfect fusion of durability, craftsmanship, and natural elegance.

Order premium-quality cladding stone from Xiamen Ji Yuan Stone today—trusted by architects, builders, and designers worldwide.

Share