Outdoor Sandstone Floor

Outdoor Sandstone Floor

Outdoor Sandstone Flooring – From Quarry to Timeless Outdoor Elegance

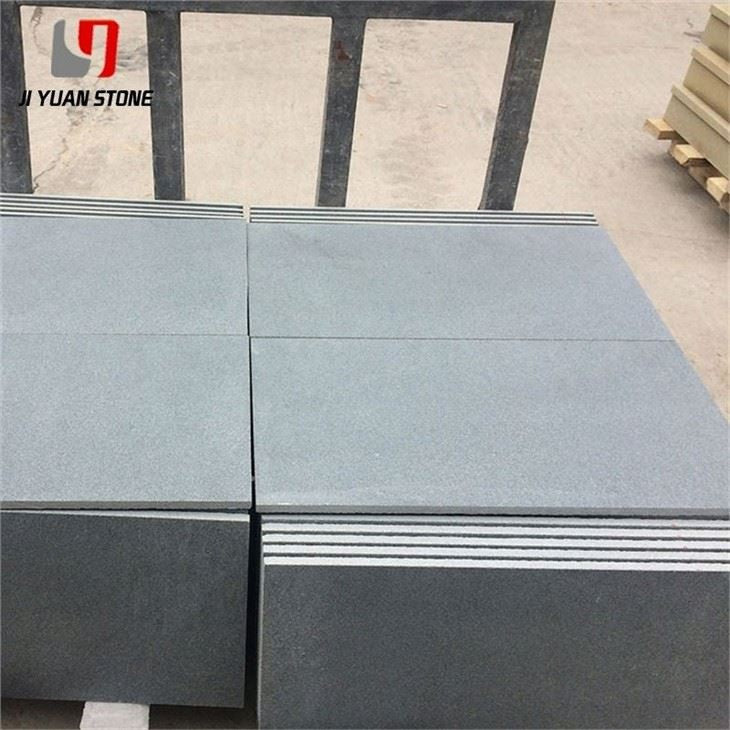

Enhance your outdoor space with our durable Outdoor Sandstone Floor. Made from high-quality sandstone, this floor is perfect for any outdoor environment. With its natural and unique texture, it will add a touch of elegance to your patio or garden. Experience the benefits of a long-lasting and low maintenance flooring solution.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

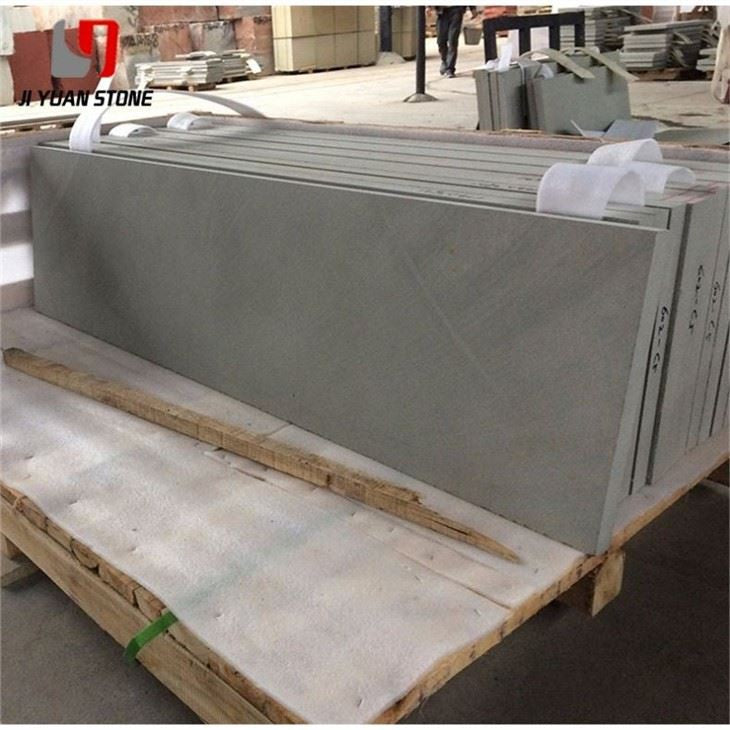

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Outdoor sandstone flooring is a natural, durable, and visually appealing solution for enhancing patios, gardens, walkways, and exterior architecture. As one of the most widely used types of decorative stone, sandstone brings rustic warmth and authenticity to any outdoor environment.

Over the last decade, breakthroughs in mining, industrial processing, and international trade have transformed the availability and versatility of sandstone. Once reserved for grand public structures, sandstone has now become a sought-after feature in modern home design—seamlessly blending natural charm with contemporary function.

🏗️ What is Building Outdoor Sandstone Flooring?

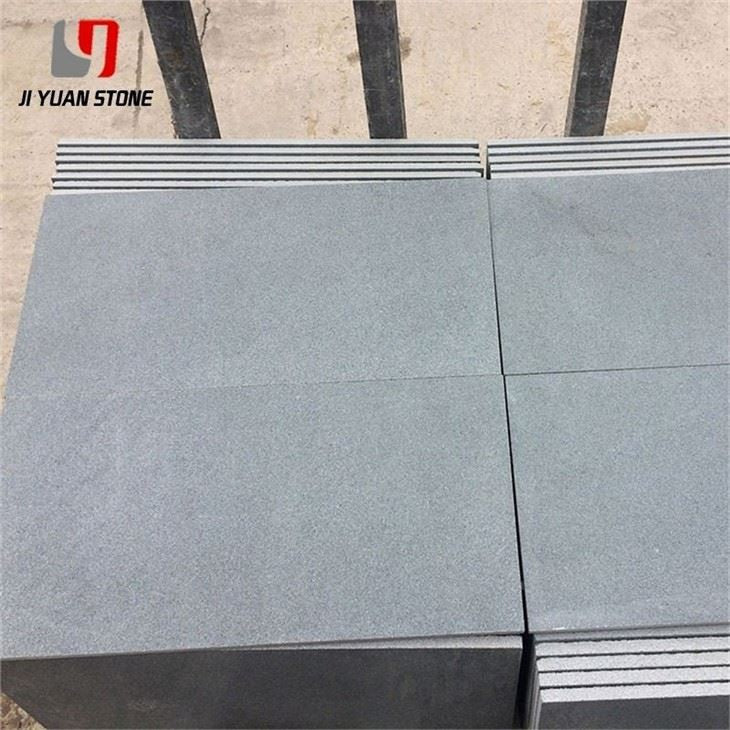

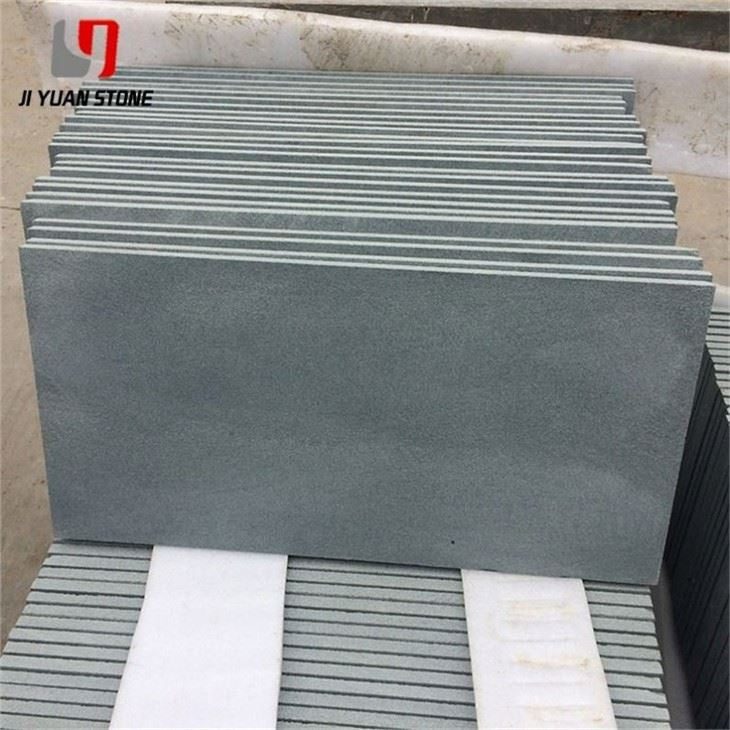

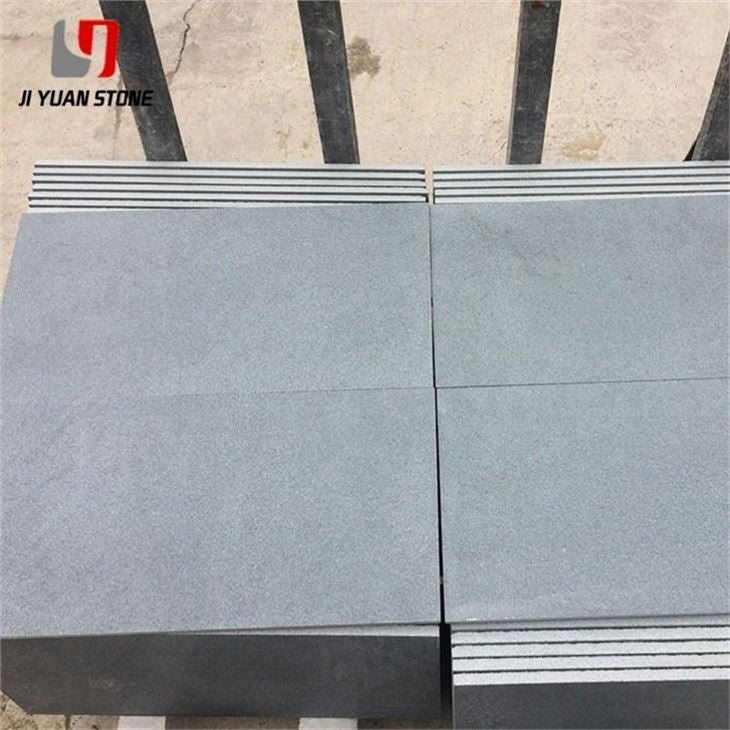

Outdoor sandstone flooring refers to natural stone slabs specifically cut and finished for use in exterior masonry and decorative applications. These stones are chosen for their strength, aesthetic appeal, and ability to withstand harsh weather conditions. They may be polished for a sleek look or left untreated for a raw, natural finish.

✅ Key Characteristics:

- Excellent durability and structural integrity

- Weather resistance for long-term outdoor use

- Natural texture and non-slip surface

- Timeless aesthetic that blends with any landscape

🛠️ Outdoor Sandstone Flooring: Step-by-Step Production & Processing

1. Cutting & Arrangement

Each sandstone slab is carefully cut according to architectural drawings. Patterns and grain alignment are prioritized to ensure visual continuity and structural reliability. Once cut, slabs are tagged with matching stickers, sprayed with protective water sealants, and stacked for the next phase.

2. Grooving & Chamfering

Boards are often grooved or chamfered to meet specific design details. Chamfering (usually at a 45° angle) softens the edges for a smoother finish but must be handled with care to prevent corner breakage—an essential aspect of stone craftsmanship.

3. Special-Shaped Plate Cutting

For intricate landscape designs or custom installations, high-pressure water jet cutting is used. Shapes are digitally programmed and precisely carved, ensuring clean lines and complex forms without compromising the integrity of the stone.

🧱 Installation & Maintenance Tips

Installing outdoor sandstone flooring requires precision and planning. Because natural stone involves variation in color, grain, and shape, it’s important to:

- Follow design schematics for consistent layout

- Use proper adhesives and leveling techniques

- Seal surfaces where needed to enhance longevity

- Regularly clean with pH-neutral solutions to maintain texture and color

With proper handling and expert installation, your sandstone flooring will deliver beauty and performance for decades.

🌟 Why Choose Outdoor Sandstone Flooring?

- Aesthetic Versatility: Available in various finishes, colors, and shapes to suit any exterior style.

- Environmentally Friendly: 100% natural stone—sourced responsibly from quarries.

- Strong & Long-Lasting: Withstands temperature changes, foot traffic, and moisture exposure.

- Customizable: Ideal for modern patios, classic walkways, garden paths, or exterior walls.

From quarry to your home, sandstone’s journey is as captivating as its presence. Whether you’re creating a tranquil backyard retreat or a bold landscape statement, our outdoor sandstone flooring offers enduring natural beauty and craftsmanship in every tile.

Share