Nero Portoro Marble Tiles

Nero Portoro Marble Tiles

Nero Portoro Marble Tiles – Where Strength Meets Sophisticated Design

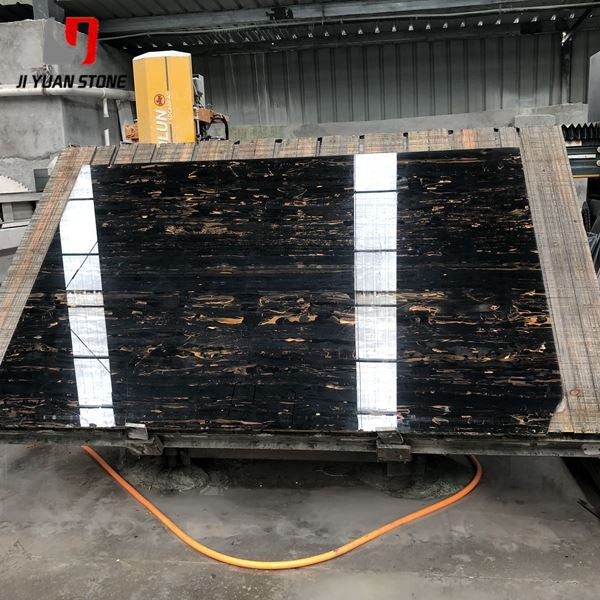

Upgrade your space with the sleek and luxurious Nero Portoro Marble Tiles. Made from high-quality Nero Portoro marble, these tiles add a touch of sophistication and elegance to any room. The unique veining and rich black color make a statement and bring a classic and timeless look to your home. Elevate your space with Nero Portoro Marble Tiles.

| Feature | Details |

|---|---|

| Surface | Polished |

| Thickness | 15mm-30mm |

| Dimension | All Sizes, Customized Sizes Welcome |

| Thickness Tolerance | +/-1mm |

| MOQ | Small Trial Orders Accepted |

| Value-added services | Free AutoCAD drawings for dry lay and book match |

| Quality Control | 100% Inspection before shipping |

| Advantage | Nice Decoration, Suitable for Large and Small Scale Building Projects. |

| Range of Application | Commercial & Residential building projects |

| Type of Application | Flooring, Wall Cladding, Vanity Tops, Kitchen Countertops, Bench Tops |

Nero Portoro Marble Tiles are a premium choice for both architectural elegance and functional durability in large-scale public infrastructure projects. Known for their striking black background with flowing golden veining, Nero Portoro brings not only timeless luxury but also the performance needed for high-traffic environments like railway station platforms, commercial lobbies, and public transport hubs.

✅ Precision Design for Large-Scale Projects

The station building referenced is an extra-large transportation hub requiring robust materials and meticulous planning. With a middle platform measuring 450m x 12m, an east platform at 450m x 20m, and a west platform at 450m x 16.75m, Nero Portoro Marble Tiles must be arranged in accordance with cap stones, safety lines, blind roads, and width regulations. For such projects, tile dimensions should not be smaller than 600mm x 600mm, and cap stone thickness should be at least 50mm, as per detailed station standards.

✅ Platform Paving Installation Process:

To ensure the long-term integrity and visual quality of Nero Portoro marble installations on public platforms, the recommended sequence includes:

1 . Base Treatment

Clean the concrete cushion thoroughly (including trial rows with dry sand and granite blocks), moisten the surface, and remove floating ash, oils, and debris. This step is essential to prevent common issues like hollowing, poor adhesion, cracks, and unevenness. Slippery surfaces should be chiseled and flushed with clean water before tiling.

2 . Elastic Line Layout

Establish control cross-lines that are perpendicular to each other and mark expansion joint separation lines. This guides the proper alignment and position of each Nero Portoro tile, ensuring precision and consistency throughout the platform layout.

3 . Layered Installation

- Begin with white hemp-washed granite in the center of the platform

- Follow by laying blind roads

- Then lay safety lines

- Finally, install cap Nero Portoro marble tiles on the edge of the platform for a high-end finish

✅ Why Choose Nero Portoro Marble Tiles?

- Striking Aesthetic: Black marble enriched with natural golden veining

- High Durability: Withstands constant foot traffic and environmental stress

- Luxurious Finish: Enhances both functionality and visual appeal in public spaces

- Large Format Tiles Available: Meets architectural requirements for modern platforms and station buildings

Nero Portoro Marble Tiles aren't just decorative—they’re engineered to meet the functional and aesthetic demands of public infrastructure. When used in high-traffic zones like train station platforms, they offer timeless beauty, precision installation compatibility, and lasting performance.

For large-scale architectural and transportation projects, Nero Portoro delivers luxury with lasting impact. Let your flooring reflect the power of design, structure, and timeless stone.

Share