Natural Stone Veneer

Natural Stone Veneer

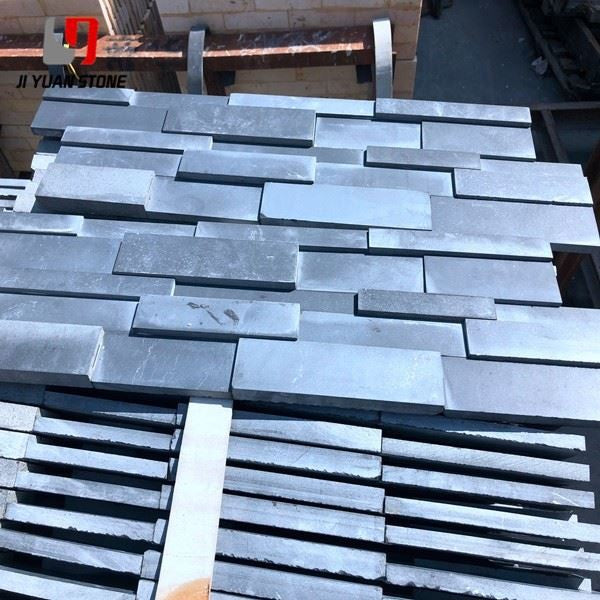

Enhance the look of your home with our Natural Stone Veneer. Made with real stone, this veneer offers a natural and timeless aesthetic. With its durable and high-quality material, it is a long-lasting investment for your home's exterior or interior. Upgrade your space with our versatile and beautiful Natural Stone Veneer.

| Feature | Details |

|---|---|

| Product | Natural Stone Veneer |

| Surface | Split face |

| Thickness | 0.8-1.2cm,1-1.5cm,1-2cm,1.5-2.5cm,2.5-3.5cm etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, stairs, steps, wall panel, flooring, veneers, slabs, coping tiles, bathtub etc |

| Colour |

Many colors for choice |

Curved Line Drawing, Roughing, and Finishing for Natural Stone Veneer

1. Extending the Trajectory Curve Line Drawing

To extend the trajectory curve, follow these steps:

- Attach the circular arc curve template with different radii to the blank section.

- Draw the extension track curve along the arc curve.

Methods for Drawing the Curve

-

Using Templates:

- Each extension trajectory curve can be drawn using a template.

-

Using Natural Stone Veneer Pieces:

- Move thin natural stone veneer pieces at an equal distance along the outer arc or inner arc curve.

✅ Line drawing must follow standard requirements for accuracy.

Curved Line Drawing, Roughing, and Finishing for Natural Stone Veneer

1. Extending the Trajectory Curve Line Drawing

To extend the trajectory curve, follow these steps:

- Attach the circular arc curve template with different radii to the blank section.

- Draw the extension track curve along the arc curve.

Methods for Drawing the Curve

-

Using Templates:

- Each extension trajectory curve can be drawn using a template.

-

Using Natural Stone Veneer Pieces:

- Move thin natural stone veneer pieces at an equal distance along the outer arc or inner arc curve.

✅ Line drawing must follow standard requirements for accuracy.

3. Finishing Process

After roughing, finishing ensures the curved lines meet production standards.

Types of Finishing

Grinding and Finishing with Grinding Discs:

- Used to refine rough contours.

- Ensures the cross-sectional shape aligns with the production order requirements.

- If a grinder cannot reach certain areas, use an engraving machine for precision grinding.

Forming Wheel Finishing:

- Uses a series of forming wheels matching the bending line’s cross-sectional shape.

- This method offers:

✅ High production efficiency

✅ Good processing quality

✅ Lower production cost

📌 The forming wheel method is a highly recommended processing technique for natural stone veneer.

By following these steps, curved lines can be processed with high accuracy, ensuring a smooth finish and seamless integration into stone veneer applications.

Share