Natural Stone Mosaic

Natural Stone Mosaic

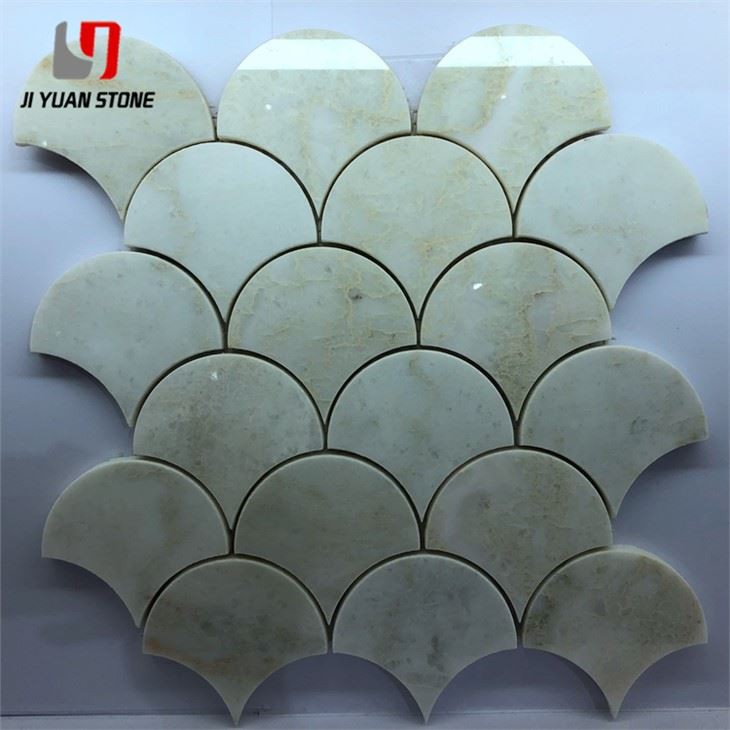

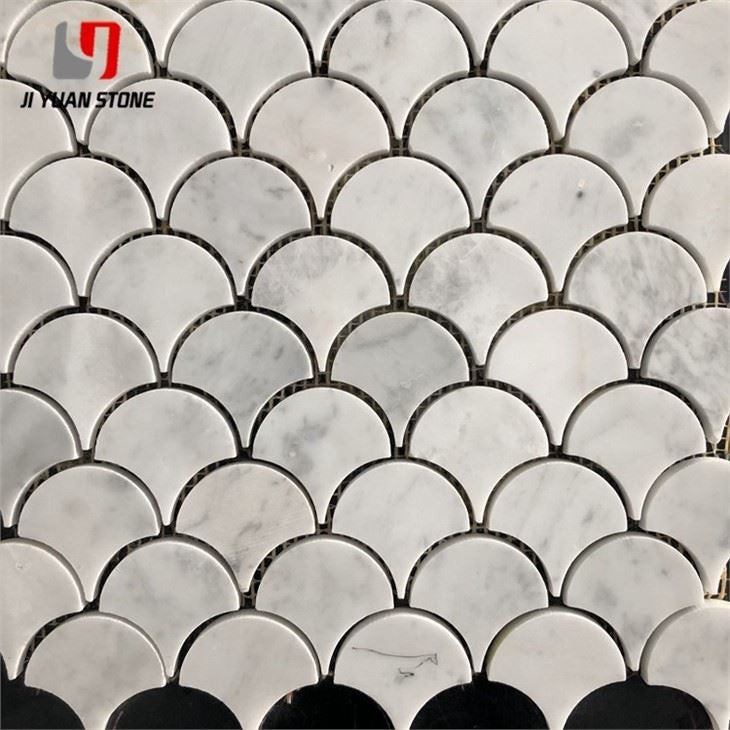

Expertly crafted from natural stone, our mosaic adds a touch of elegance to any space. With its unique and intricate design, it brings a timeless and sophisticated feel to your home. Made from 100% natural materials, you can trust in its durability and long-lasting beauty.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Material | Marble stone |

| Sheet size |

|

| Chip size |

|

Natural stone mosaic are widely used, hotels and home improvement can come in handy. Stone mosaics mainly include marble mosaics, granite mosaics, jade mosaics, travertine mosaics, special-shaped mosaics, artistic waistline mosaics and other products.

The production of stone mosaic mosaics is mainly the processing of stone mosaic blocks. The raw materials for the mosaics mainly come from the leftover material left by the large slab stone processing factory in the cutting board cutting, preferably the leftover material from the thin board cutting under 1cm, stone The more varieties and designs, the better.

Natural stone mosaic parquets mostly use matt or rough surfaces, and some use polished surface stones. The size is generally 2-3 cm square. You can choose a larger surface size according to your needs. For small batch production or production of unit price mosaic stone mosaic products, you can use a small desktop cutting machine with a diamond saw blade to cut mosaic mosaics, or use a small hydraulic cutting machine with upper and lower cutting abrasives to process mosaic blocks, stone processing Granite mosaics can only be cut piece by piece; if you want to mass produce regular-shaped marble mosaic pieces, it is feasible to use a bridge-type bridge cutting machine. Several plates can be stacked and fixed with special fixtures. , It can cut several parquet pieces at a time, and the processing efficiency is high.

The natural stone mosaic tiles on the polished surface can be cut directly from the scraps of the light board. However, the matte or matte-faced parquet blocks need to be matte-faced. First, cut the edges and corners of discarded boards with a thickness of 1-2cm and different colors into squares, rectangles, triangles, rhombuses, or other regular parquet blocks that can be used as the basic shapes of parquet, and put them into the drum. When the drum rotates, the plates rub against each other, and finally form a matte parquet with regular shape, rounded corners, matt surface, and uniform abrasion.

Share