Natural Stone Façade

Natural Stone Façade

Natural Stone Façade for Bathroom – Combining Elegance, Functionality, and Durability

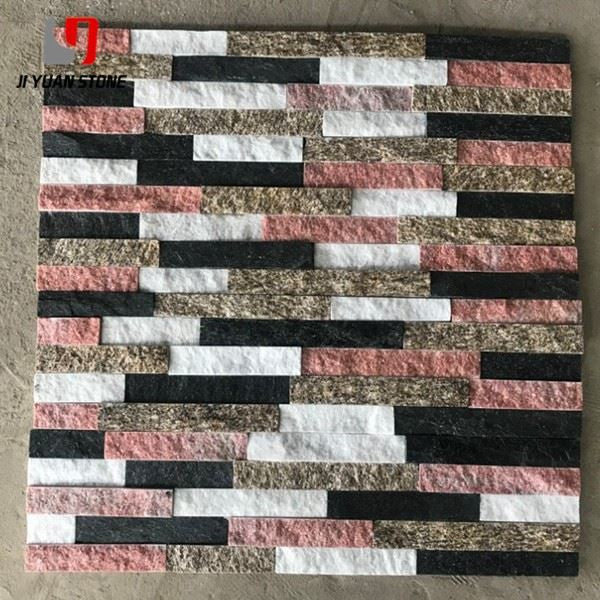

This Natural Stone Façade offers a durable and stylish exterior solution for any building. Made from natural stone, it provides a long-lasting and unique look for a professional and sophisticated appearance. With its timeless beauty, it adds value and curb appeal to any property.

| Feature | Details |

|---|---|

| Product | Natural Stone Façade |

| Surface | Split face |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, stairs, steps, wall panel, flooring, veneers, slabs, coping tiles, bathtub etc |

| Colour | Many colors for choice |

| Material | Granite, marble, slate, quartz |

| Sizes | 60x15cm |

| Finished | Natural surface |

| Usage | Indoor and Outdoor decoration |

| Main Market | Europe, America, Russia, Australia and the Middle East. |

| Package | Inner box, Strong seaworthy and fumigated wooden crates. |

| Payment | T/T (30%deposit, 70%balance payment against the B/L copy).L/C |

| Delivery | Around 20 days after receiving the deposit. |

| MOQ | 100square meters |

| Our Advantage | Strict quality control |

Enhance your bathroom with the timeless beauty and resilience of natural stone façade. Ideal for luxurious interiors, especially in wet zones, natural stone cladding elevates design aesthetics while offering unmatched longevity. From accent walls to complete bathroom renovations, our stone facades are crafted to meet both style and structural integrity requirements.

🛁 Professional Construction Process for Bathroom Natural Stone Façade

To achieve a flawless and long-lasting finish, proper construction methods are critical. Here's a detailed look at the standard bathroom installation process:

🔧 Site Preparation and Layout:

- The construction team must complete wall and floor stone layout based on architectural drawings and the site’s actual dimensions.

- Design layouts are subject to review and final approval by the property owner.

- Clearly mark the location of switches, sockets, and water supply/drainage points on both layout plans and on-site.

💧 Waterproofing:

Water storage tests must be conducted on the bathroom structure's floor before waterproofing.

The general contractor manages the test, followed by approval from the supervisor and owner.

Waterproofing specifications:

- Ground: Covered with waterproof paint.

- Wall flanging: Not less than 300mm height, and minimum 1.2mm thickness.

- Shower walls: Full-height waterproofing, up to ceiling level.

🚫 No entry is allowed during the waterproof curing period to maintain effectiveness.

🚿 Fixtures & Cabinet Installation

The bathroom vanity cabinet is pre-fabricated in the factory based on detailed drawings.

It is installed on-site with upper and lower door suction mechanisms.

The cabinet back is treated with anti-corrosion measures.

Tiling Requirements:

- Wall tiles: 200mm x 300mm

- Floor tiles: 300mm x 300mm

- Used beneath and behind the cabinet for extra durability.

🚰 Plumbing Guidelines

- Shower and bathtub faucets are installed per design drawings.

- Washbasin water supply point: 500mm above floor level.

- Hot & cold water pipe spacing: Between 150–170mm.

- Toilet water supply: Follows exact product model specifications.

🧱 Why Choose Our Natural Stone Façade?

- ✅ Resistant to moisture, heat, and humidity

- ✅ Luxurious textures and natural tones

- ✅ Suitable for floors, walls, and wet areas

- ✅ Long-lasting investment in bathroom aesthetics

- ✅ Easy to maintain and clean

🌍 Trusted Supplier – Xiamen Ji Yuan Stone

Backed by over a decade of industry expertise, Xiamen Ji Yuan Stone is a leading supplier of natural stone materials. We operate:

- 30+ Quarry Partnerships Across China

- 2 Exclusive Quarries & 3 Processing Bases

- Advanced Machinery, Skilled Workers & Strict Quality Control

We ensure that every product meets international quality and design standards for premium architectural finishes.

Transform your bathroom into a luxurious retreat with expertly installed natural stone façades. Built to last. Designed to impress.

Share