Natural Sandstone Flooring

Natural Sandstone Flooring

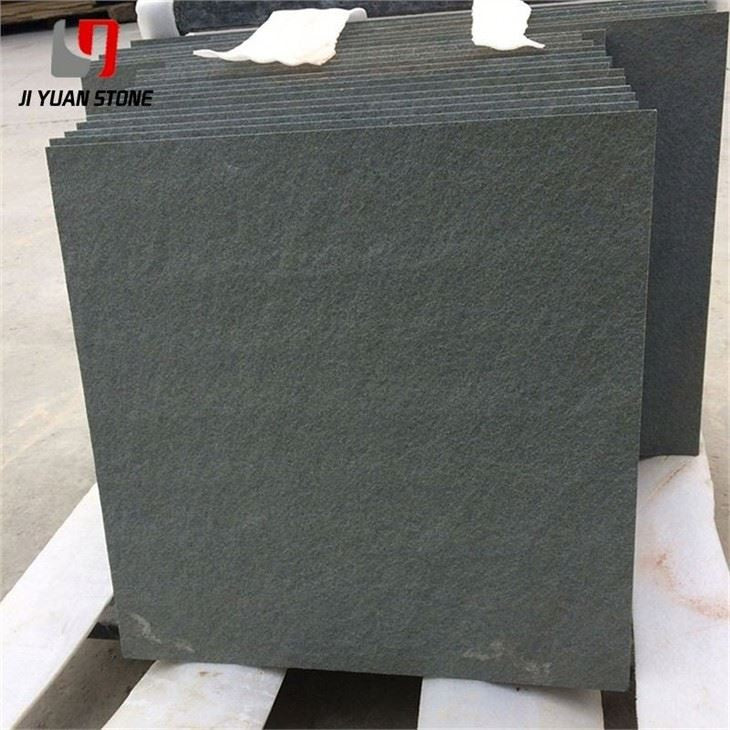

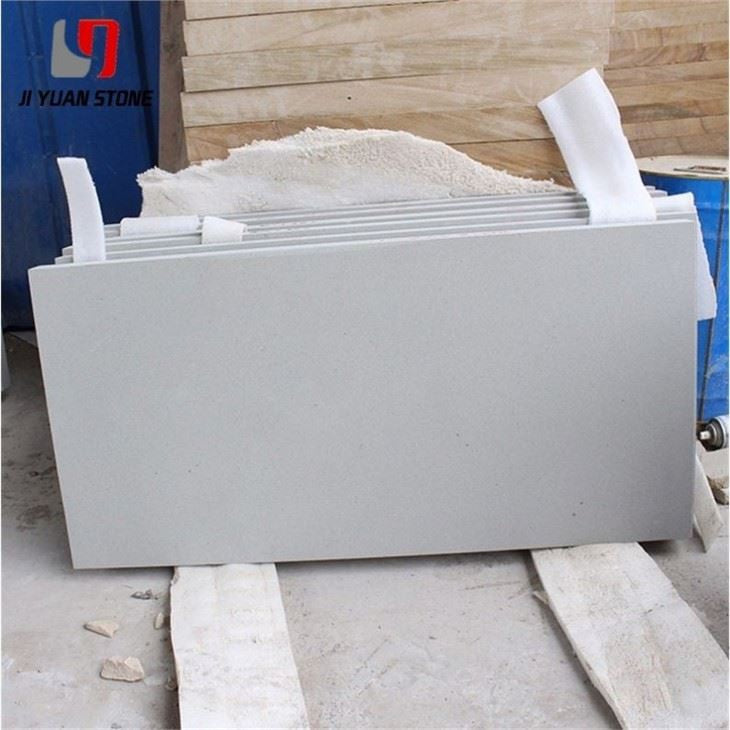

Natural Sandstone Flooring is a durable and long-lasting option for any indoor or outdoor space. Made of natural sandstone, this flooring is resistant to water and weather elements, making it ideal for high-traffic areas. With its unique earthy tones and textures, it adds a touch of natural beauty to any space.

| Feature | Details |

|---|---|

| Materia | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Name | Sandstone for Slabs and Tiles |

| Our Advantage | "Own Mine"+"Factory Price"+"High Quality" |

| Product size |

|

| Thickness | 10mm, 15mm, 18mm, 20mm, 30mm, 50mm, 100mm, etc. |

| Applications | Tiles, Wall cladding, Flooring, Countertops, kitchen tops, Vanity tops,random, carvings columns , slab,etc |

| Tolerance | Be calibrated from +-1-1.5mm |

Analysis: Is Natural Sandstone Flooring Suitable for Ground Design?

Recently, I was invited by a decoration company to conduct a technical discussion on a project in Hangzhou. The issue at hand was alkali reversion caused by improper maintenance of the natural sandstone flooring. Despite multiple attempts—at least five rounds of crystallization and polishing—the problem persisted, leading to frustration from the property owner. After thorough consultation, it was concluded that the stone material used in the project was soft and, according to some, not suitable for flooring.

However, is soft natural sandstone flooring truly unsuitable for floor paving?

The Answer: Yes, It Can Be Used!

The primary cause of alkali reversion in stone surfaces is irregular installation and maintenance processes, rather than the stone's inherent quality. Whether using white cement or black cement, both contain calcium hydroxide, which, when hydrated, seeps through the stone's pores. Once exposed to air, this moisture evaporates, leaving behind crystalline residues such as calcium oxalate or calcium fluorosilicate when reacting with elements in the curing agents. These substances, combined with resin wax from crystallization agents, often form sticky residues, exacerbating the problem.

How to Prevent Alkali Reversion in Soft Natural Sandstone Flooring

Yes, there is a solution! The key to preventing alkali reversion lies in dry grinding followed by a crystal steel ceramic glaze treatment.

- The crystal steel ceramic glaze treatment uses nano-polymer materials that do not contain oxalic acid or resin wax, ensuring the stone's gas permeability.

- Even if calcium hydroxide hydrate reaches the surface, it will not react or stay, as it evaporates with water, preventing residue buildup.

By implementing proper installation and maintenance techniques, soft natural sandstone flooring can be effectively used for ground paving without alkali-related issues.

Share