Natural Sandstone Floor

Natural Sandstone Floor

Natural Sandstone Floor – Accurate Layout and Metal Frame Installation for Long-Lasting Durability

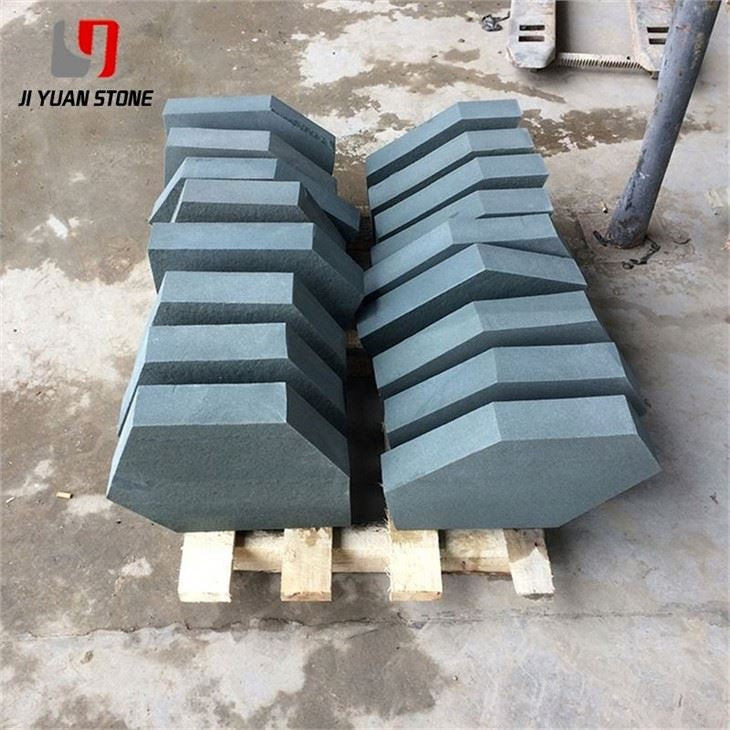

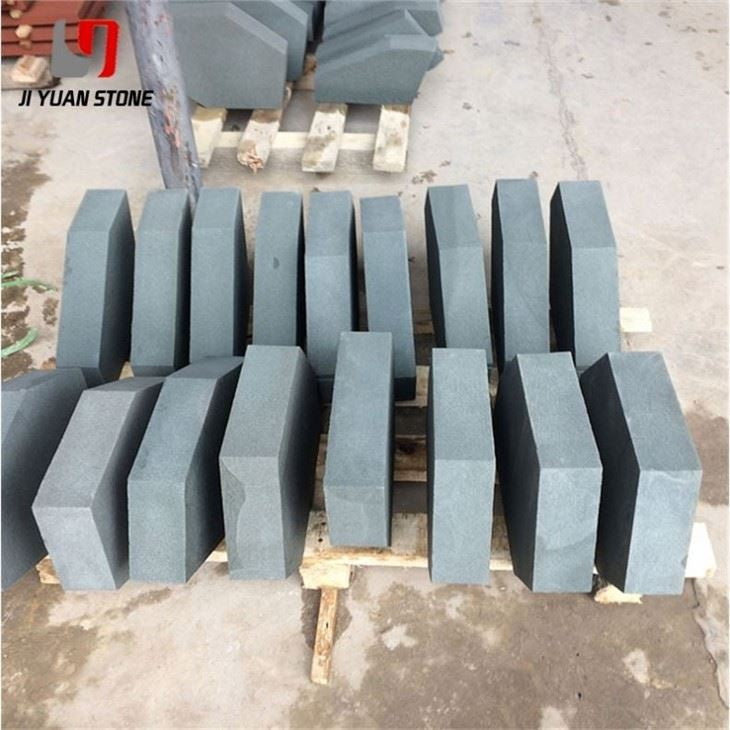

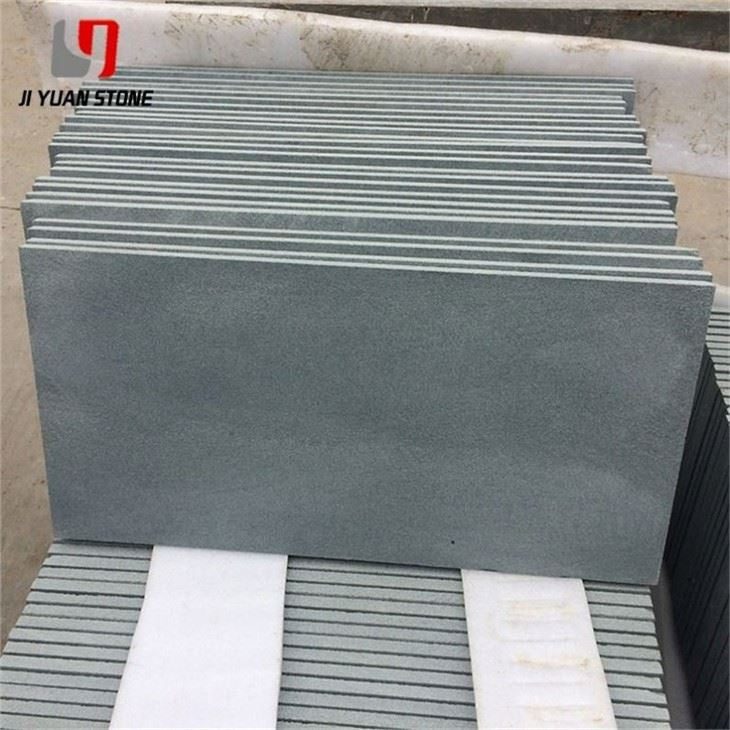

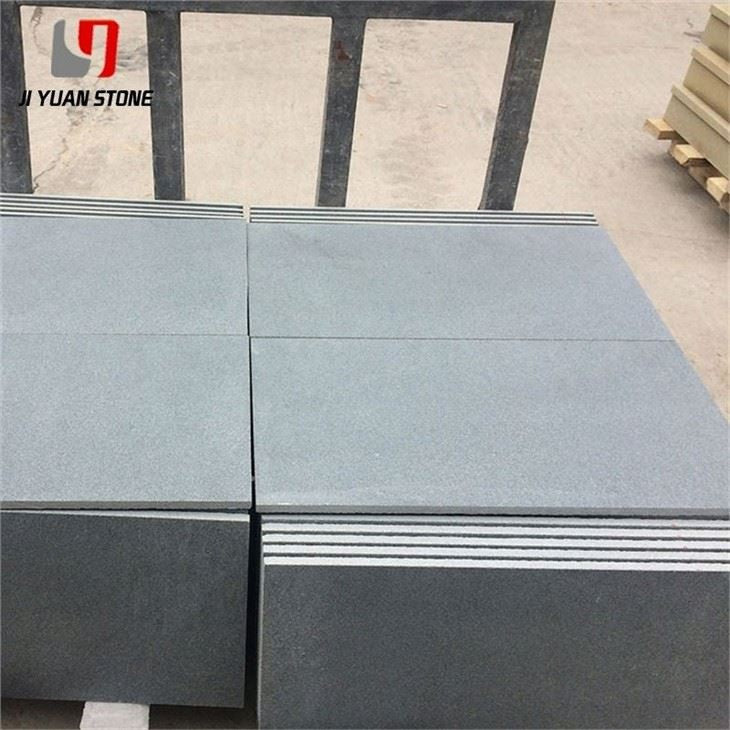

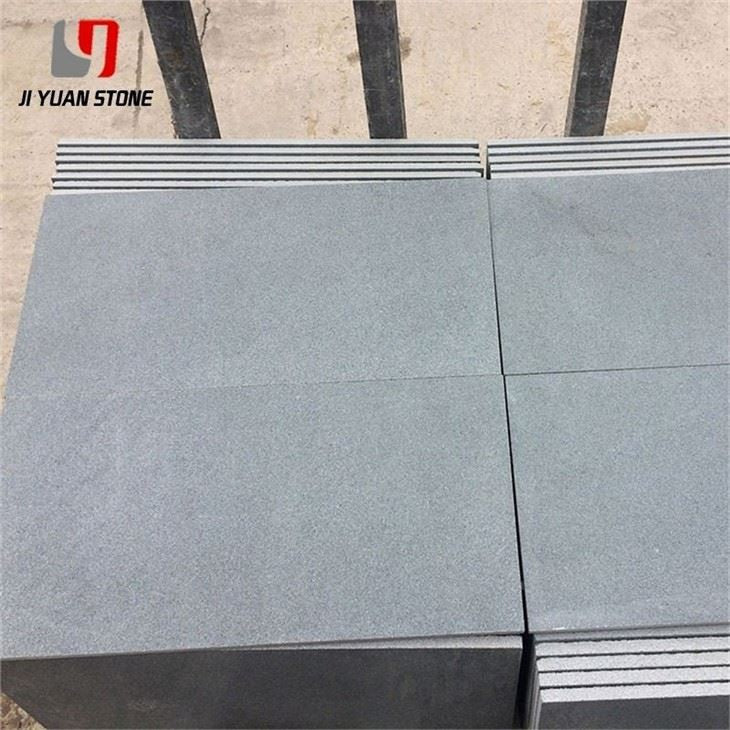

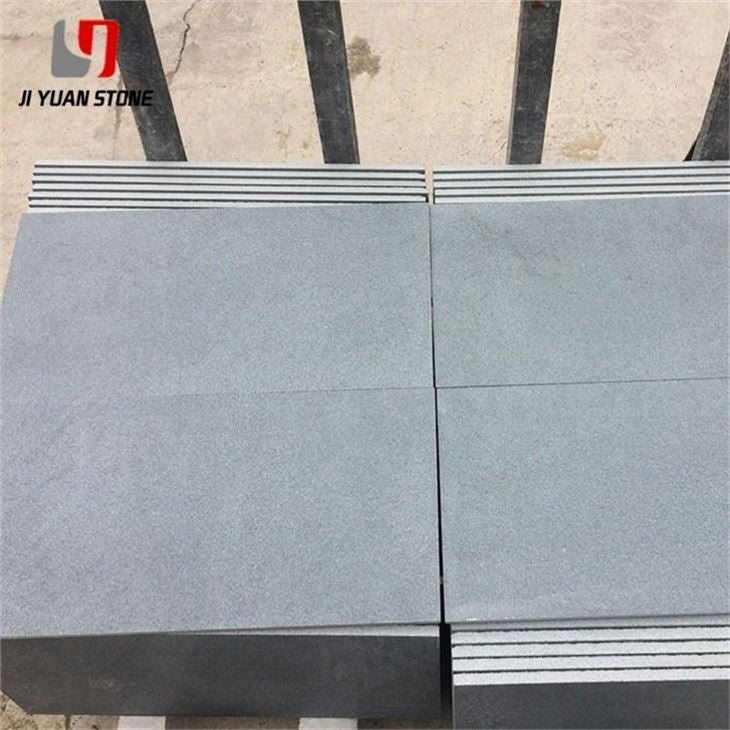

Elevate your home with our Natural Sandstone Floor. Made from natural sandstone, this high-quality flooring option offers durability and a timeless look to any space. With its unique natural patterns and textures, it adds a touch of elegance to any room. Upgrade your home today.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

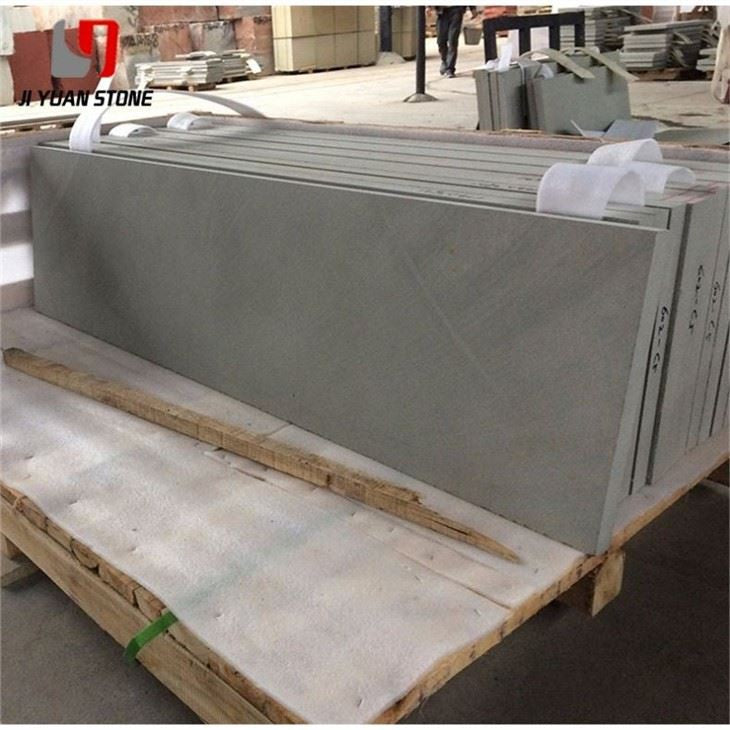

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Natural sandstone flooring combines aesthetic appeal with structural integrity, making it a preferred choice for both indoor and outdoor applications. To ensure a flawless finish and lasting durability, precise measurement, layout, and sturdy metal frame installation are critical.

📏 Accurate Measurement and Layout

The first step in natural sandstone floor installation is precise positioning:

- Use the datum axis and level points of the main structure as reference.

- Verify corner positions, axis points, and height sections against curtain wall construction drawings to maintain accuracy.

- Control measurement distribution errors carefully to avoid accumulation.

- Carry out measurement and payout in calm weather (wind force ≤ level 4) with proper wind shelter measures.

🏗️ Metal Frame Processing and Installation

The metal frame provides essential support and stability for the natural sandstone floor. The process involves:

1 . Layout and Blanking

- Check positioning per lofting drawings and process blanks on-site for exact sizing.

2 . Mullion Installation

- Fix mullions at both ends of the elevation, pull guide wires, and install middle mullions sequentially.

- Control lines lead to mullions, verified with level rulers for precision.

3 . Metal Beam Installation

- Beams must be perpendicular to mullions and installed to design specifications.

- Protect adjacent surfaces before welding. Use symmetrical welding to minimize deformation.

- Inspect weld quality, remove slag, and apply anti-rust paint to all welding points and seams.

4 . Anti-Rust and Structural Compliance

- Steel surface anti-rust treatment follows national standards GB 50205 and GBJ 17.

- Welding and bolt connections comply with GBJ 17 and JGJ 81 regulations.

5 . Lightning Protection

- The natural sandstone floor wall’s lightning protection must connect effectively with the main structure’s system per design and standards.

6 . Fireproof Layer Installation

- Use hot-dip galvanized steel plates (≥1.5mm thickness) for lining; aluminum plates are prohibited.

- Apply fireproof glue at seams and sealant to ensure fire resistance.

🔧 Ensuring Quality and Safety

This comprehensive approach guarantees that natural sandstone flooring not only enhances the beauty of any space but also meets strict safety, durability, and design standards. Proper installation and adherence to national codes ensure your investment in natural sandstone flooring stands the test of time.

Share