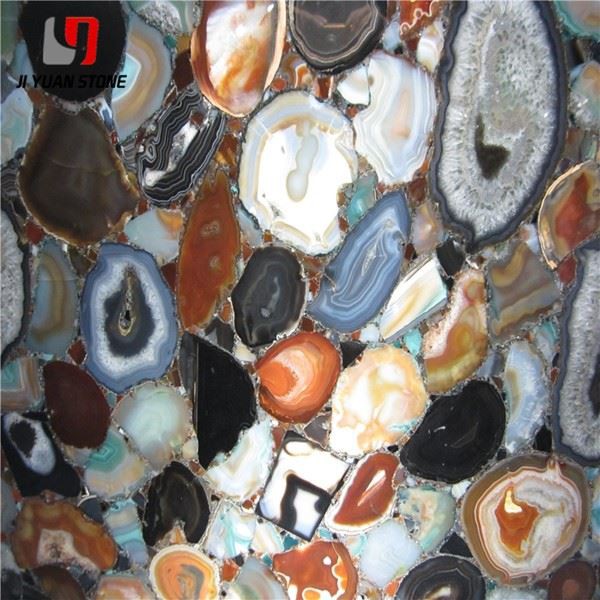

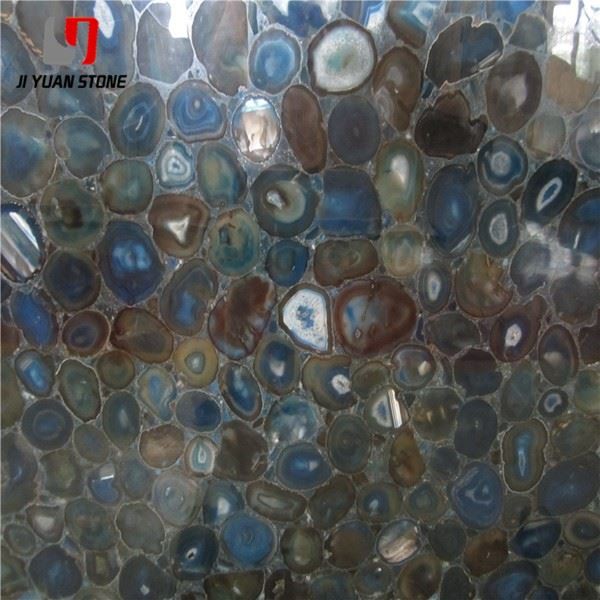

Multi Color Agate Stone Slab

Multi Color Agate Stone Slab

Premium Multi-Color Agate Stone Slab – For Luxurious Custom Designs

Expertly crafted with multi colored agate stone, this slab brings a unique touch to any space. With its natural variations and beautiful hues, it adds a sense of depth and texture to your decor. Perfect for adding a touch of elegance and sophistication to your home.

| Feature | Details |

|---|---|

| Product Name | Multi Color Agate Stone Slab |

| Material | 100% agate gemstone semi-precious stone |

| Surface Finished | Honed,Polished |

| Finished Products | Floor Tiles, Wall Cladding, Countertops, Windowsills, Special-Shaped Tiles, Small Slabs, Swimming Pool, Steps, Wall Panel, Flooring, Veneers, Slabs, Coping Tiles etc. |

| Color | Yellow,Black,White,Red,Purple Wood,Green,Grey,Pink,Rainbow,Pink,Tiger Eye etc |

| Size | Any sizes customized are welcome |

| Edge Available | Polished, Bush Hammer, Flat, Flamed, Eased, Beveled, Bullnose, Ogee, Cove, Dupont, laminated, non-laminated and etc. |

| Thickness | 10/15/18/20/25/30mm etc |

| Usage | Indoor/Outdoor Decoration, For floor or wall, Counter tops, Vanity tops |

| Packing | Seaworthy Wooden Crate |

Transform your architectural and interior design projects with our Multi-Color Agate Stone Slab, known for its vibrant hues and natural elegance. Perfect for high-end applications like feature walls, countertops, and custom spiral staircases, this decorative stone offers both durability and a stunning aesthetic.

Arc Plate Blank Processing for Multi-Color Agate Stone Slabs

Our advanced arc plate processing method ensures precision and quality for complex designs, especially in curved structures such as spiral staircases. Here's a breakdown of our professional workflow:

1. Open Arc Plate Blank

Each arc plate blank used for modeling must meet strict technical criteria:

- Machining allowance: 30–40 mm in both the height and chord length directions.

- Flat end faces: Ensures precise alignment with standard templates.

2. Arc Plate Blank Cutting

Using high-precision tools like computer-controlled diamond beaded wire saws and water jet machines, the arc plates are cut meticulously:

- Vertical bending lines: +5mm machining allowance.

- Flat bending lines: Additional allowance varies by material quantity.

- Engraving machine used directly for curved lines under 40mm thickness.

- Each piece is individually numbered for accurate assembly.

3. Arc Plate Blank Reinforcement

For slabs with cracks or natural fissures, structural reinforcement is applied using:

- Fiber mesh

- High-strength glue

- Steel bars

This ensures long-term durability without compromising the aesthetic value.

4. Arrangement and Numbering

To maintain consistency in color and texture across curved installations:

- Arc plate blanks are arranged based on the layout of the spiral staircase.

- Each piece is numbered in sequence to ensure accurate placement during installation.

5. Arc Blank Parts

As per production plans or elevation drawings:

- Blanks with opposite curves are divided into parts.

- Numbering helps maintain proper identification for seamless processing.

6. Inspection

Every blank undergoes strict quality checks:

- Chord length

- Thickness

- Height

- Surface finish

These inspections ensure each arc blank meets the required precision standards.

7. Programming

We utilize Jingdiao programming software to convert design drawings into machine-readable instructions. Each program is created using large sample drawings of the desired curvature.

8. Program Simulation

Before actual production, simulations are run to validate:

- Cutting path

- Processing accuracy

- Elimination of programming errors

This simulation guarantees smooth execution during manufacturing.

Why Choose Our Multi-Color Agate Stone Slabs?

- Unique, naturally vibrant color patterns

- Ideal for architectural features, countertops, and luxury installations

- Engineered for durability and structural integrity

- Customization options available for spiral staircases and curved surfaces

Order now and elevate your next project with the timeless beauty and precision of our Multi-Color Agate Stone Slabs.

Share