Multi Color Agate Slab

Multi Color Agate Slab

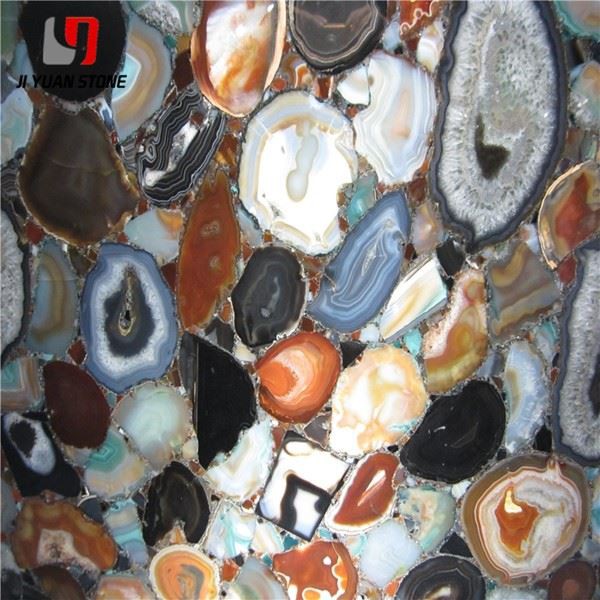

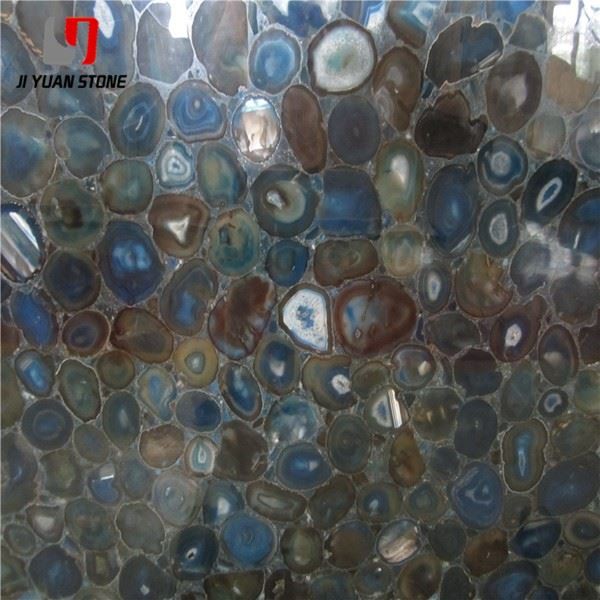

Multi-Color Agate Slab – Precision-Cut Natural Stone for Custom Curved Applications

Experience the unique beauty of our Multi Color Agate Slab. Each slab showcases an array of mesmerizing colors, adding an eye-catching element to any space. Handcrafted from natural agate, each slab is one of a kind. Enhance your home decor with the distinctive elegance of our Multi Color Agate Slab.

| Feature | Details |

|---|---|

| Product Name | Multi Color Agate Slab |

| Material | 100% agate gemstone semi-precious stone |

| Surface Finished | Honed,Polished |

| Finished Products | Floor Tiles, Wall Cladding, Countertops, Windowsills, Special-Shaped Tiles, Small Slabs, Swimming Pool, Steps, Wall Panel, Flooring, Veneers, Slabs, Coping Tiles etc. |

| Color | Yellow,Black,White,Red,Purple Wood,Green,Grey,Pink,Rainbow,Pink,Tiger Eye etc |

| Size | Any sizes customized are welcome |

| Edge Available | Polished, Bush Hammer, Flat, Flamed, Eased, Beveled, Bullnose, Ogee, Cove, Dupont, laminated, non-laminated and etc. |

| Thickness | 10/15/18/20/25/30mm etc |

| Usage | Indoor/Outdoor Decoration, For floor or wall, Counter tops, Vanity tops |

| Packing | Seaworthy Wooden Crate |

Enhance your architectural masterpieces with our Multi-Color Agate Slabs, renowned for their stunning, natural patterns and excellent workability. Ideal for luxury interiors and spiral staircases, these slabs are processed using advanced engraving machine techniques to deliver precise, intricate curved designs.

Engraving Machine Processing for Multi-Color Agate Slabs

To achieve high-quality results in customized curved structures like spiral staircases, we use engraving machines that enable detailed craftsmanship for flat and vertical bending lines.

1. Introduction to Engraving Machine Processing

Unlike machining centers, engraving machines are more commonly available among Multi-Color Agate slab manufacturers. While engraving machines can't use saw blades and instead rely on milling cutters that remove material bit by bit, they are highly effective in:

- Handling flat curved lines, such as handrails on spiral staircases

- Processing multiple curved lines simultaneously, improving overall efficiency

For vertical bends, care is taken to ensure that the arch height remains within functional limits for accuracy and ease of processing.

2. Process Flow of Engraving Machine Processing Curved Lines

Our detailed, step-by-step workflow ensures quality and precision throughout production:

1 . Material Selection – Choose blocks based on texture, color, and crack-free quality, especially in white agate varieties.

2 . Blank Opening

3 . Arc Plate Blank Cutting

4 . Arc Plate Blank Reinforcement

5 . Arc Plate Blank Arrangement & Numbering

6 . Arc Plate Blank Parting

7 . Inspection – Check chord length, thickness, height, and surface finish.

8 . Programming – Designs are translated into machine code using advanced software.

9 . Program Simulation – Prevents errors before physical processing.

10 . Positioning Die Making

11 . Zero Point Setting

12 . Blank Loading Material

13 . Machine Tool Debugging

14 . Zero Point Setting (Confirmed Again)

15 . Trial Processing

16 . Inspection

17 . Batch Modeling

18 . Unloading

19 . Final Inspection

This rigorous workflow ensures each slab matches the design specification, especially for projects requiring precision-cut curved components.

3. Specific Processing Technology for Curved Lines

Material Selection:

The initial block selection is crucial to the final product's quality. Each block must:

- Match the color and texture specifications of the project

- Be free from structural cracks, particularly in white Multi-Color Agate slabs

- Ensure uniformity in aesthetic and mechanical performance

Why Choose Our Multi-Color Agate Slabs?

- Precision-cut using engraving machines for detailed curves and lines

- Ideal for luxury interiors, spiral staircases, and custom curved installations

- Naturally unique patterns with vibrant colors

- Carefully selected and inspected for top-grade quality

- Processed using a comprehensive, quality-driven workflow

Upgrade your design with our Multi-Color Agate Slabs – engineered for beauty, precision, and long-lasting performance in both residential and commercial spaces.

Share