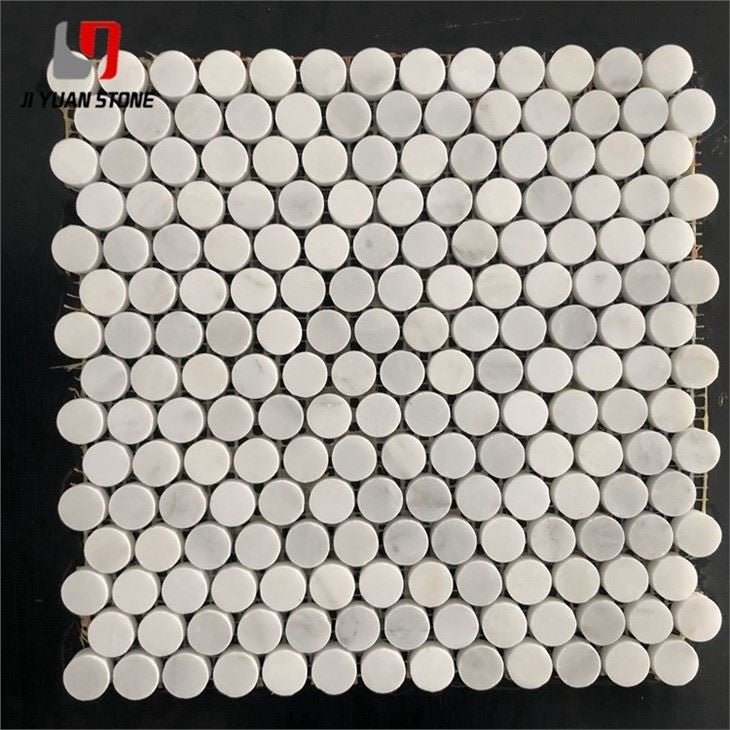

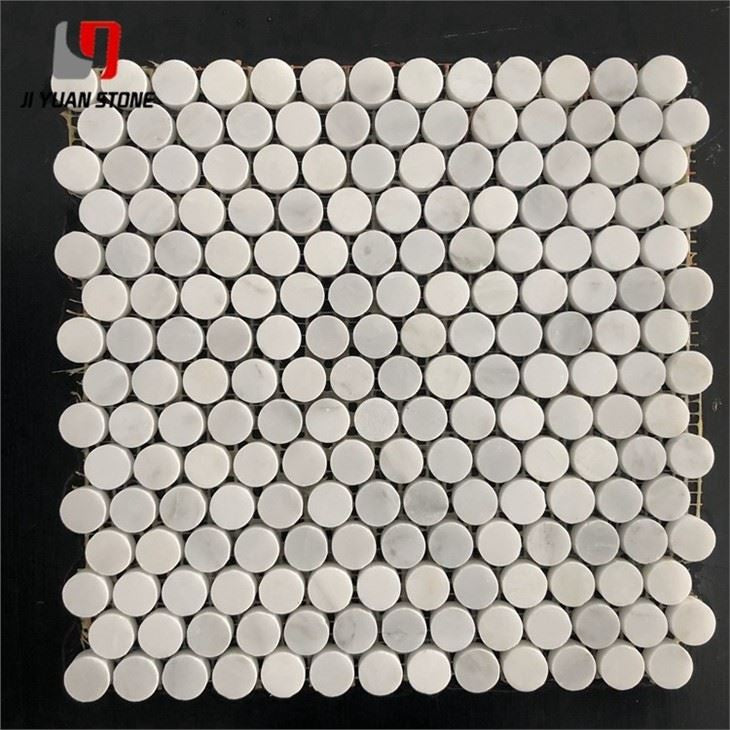

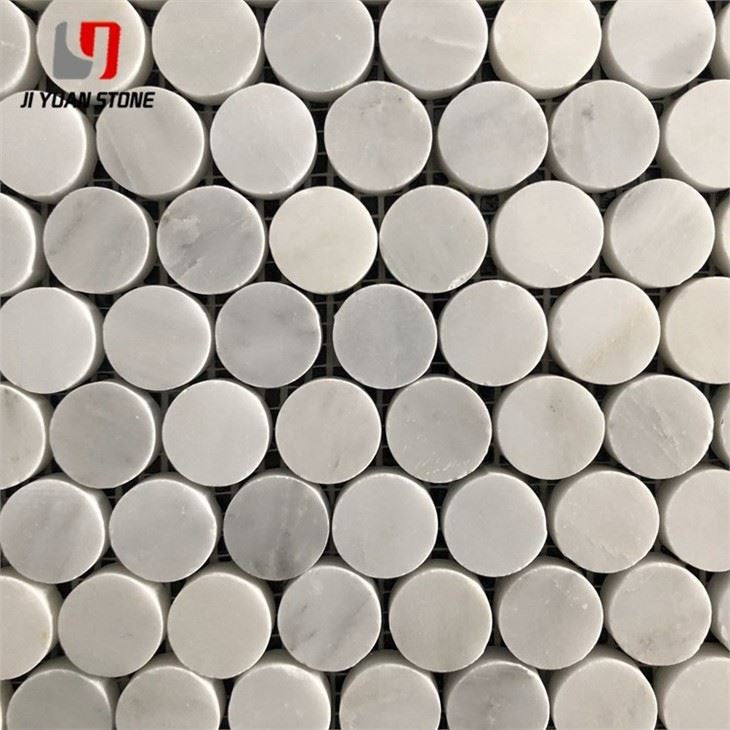

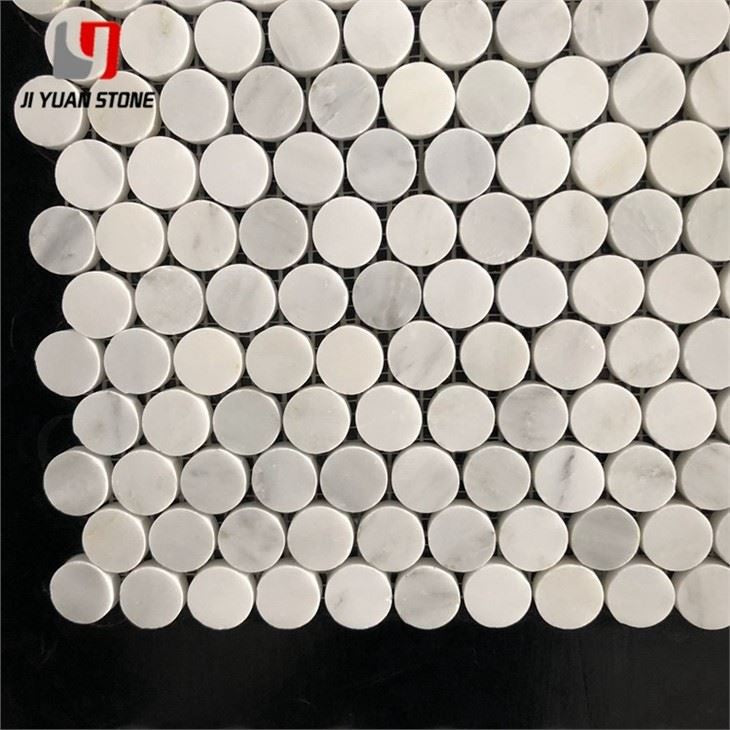

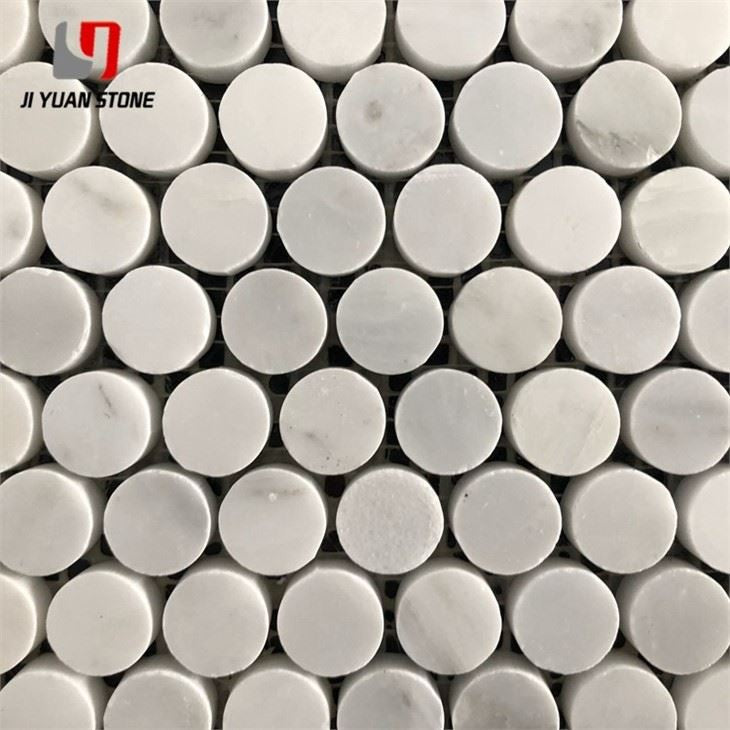

Marble Penny Tile Floor

Marble Penny Tile Floor

Enhance your space with the elegant and timeless Marble Penny Tile Floor. Crafted from high-quality marble, these tiles add a touch of luxury and sophistication to any room. Its durable and water-resistant properties make it a practical and attractive choice for both residential and commercial spaces. Elevate your interior design with this classic flooring option.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Regular size | 305 x 305mm, cut-to-size, or according to customer's requirement |

| Thickness | 7mm,10mm |

| Color | Black, grey, yellow, rusty, white, pink, multicolor etc. |

| Finishing | Honed ;split :mushroom ;picked ;stick with cement or glue |

| Package | Carton box and wooden crate,plywood pallet or plywood crate |

| Delivery time | Sample-- abt 2-5days Order ---- abt 10-20days after the deposit. |

| Payment | T/T;30%deposit and 70%blance against copy of B/L; or L/C at sight. |

| Loading port | Guangzhou/Xiamen/Shenzhen/Foshan |

| Min order | 50 square meters |

| Export Market | European, north America, Australia and middle east |

Marble Penny Tile Floor: Material, Processing, and Quality Standards

The marble penny tile floor is crafted from natural marble through a specialized process without the use of chemical dyes. Marble mosaics retain the unique and primitive colors of the natural stone, enhancing their aesthetic and artistic value.

1. Material Selection

Material selection should follow parquet material requirements to ensure consistency. When using non-standard thicknesses, it is essential to maintain color uniformity between conventional and unconventional materials.

2. Material Preparation

- For non-standard thicknesses (e.g., 25mm, 30mm, 35mm), materials should be cut using specialized cutting equipment.

- Any plates requiring polishing should be polished and refined before proceeding to the next step.

3. Cutting Board

The boards must be cut to the specified dimensions based on the production processing sheet or design drawings.

4. Cutting Process

- A multi-knife machine is used to cut mosaic particles according to the specified pattern and dimensions.

- A small cutting machine is used for special-shaped plates.

- Some complex designs may require waterjet cutting for precision.

5. Printing and Assembling Drawings

A 1:1 scale drawing should be printed based on the parquet design to serve as a reference during assembly. The larger the drawing, the better, as it minimizes errors caused by excessive stitching.

6. Jigsaw Assembly

- Ensure that pieces are placed correctly during assembly to avoid misalignment.

- Special-shaped pieces may require trimming with scissors or a mill.

- Pay close attention to floral and geometric designs to ensure accuracy.

- After assembling a product, check for size and pattern consistency.

- The process product quality inspector must approve the assembly before applying mesh reinforcement.

- Mesh-cutting and gluing should be done carefully.

- Small pieces (under 1m) should be dried in an oven.

- Larger pieces (over 1m) should be air-dried naturally.

Quality Standards for Marble Penny Tile Floors

1. Color

- The parquet design should reflect nobility and elegance.

- Colors must be layered, coordinated, and uniform.

- The same stone must maintain consistent color without visible variations, spots, or lines.

2. Pattern Alignment

- The pattern should be coherent, rhythmic, and well-structured.

- Disorganized patterns should be avoided.

3. Flatness

- Check the flatness of the marble penny tile floor with a feeler gauge (acceptable deviation: less than 1mm).

- There should be no warping of the board surface.

4. Surface Quality

- Mosaics must not have visible defects such as:

- Sand holes

- Cracks

- Glue traces

- Stains

- Color discrepancies

- Mold spots

5. Luminosity

- The luminosity should be at least 85° or 90% of the agreed plate luminosity.

- The luminosity difference in inspected areas must not exceed 10°.

6. Seam Alignment

- The gap between adjacent mosaic components must be ≤1mm.

7. Assembly Quality

- Alignment deviation between parquet components must not exceed 1mm/m.

- Stitching deviations should be ≤1mm, except for intentionally stitched parquet designs.

-

Outer dimension deviations:

- Small parquet: ≤0.5–1mm

- Large parquet (≥5000mm): ≤5mm (can be slightly increased).

-

Geometric Precision:

- Rectangular, square, and parallelogram mosaics must have straight diagonals.

- Curved marble penny tiles must have smooth edges.

- Triangular pieces must have sharp corners without chipping.

Share