1

/

of

9

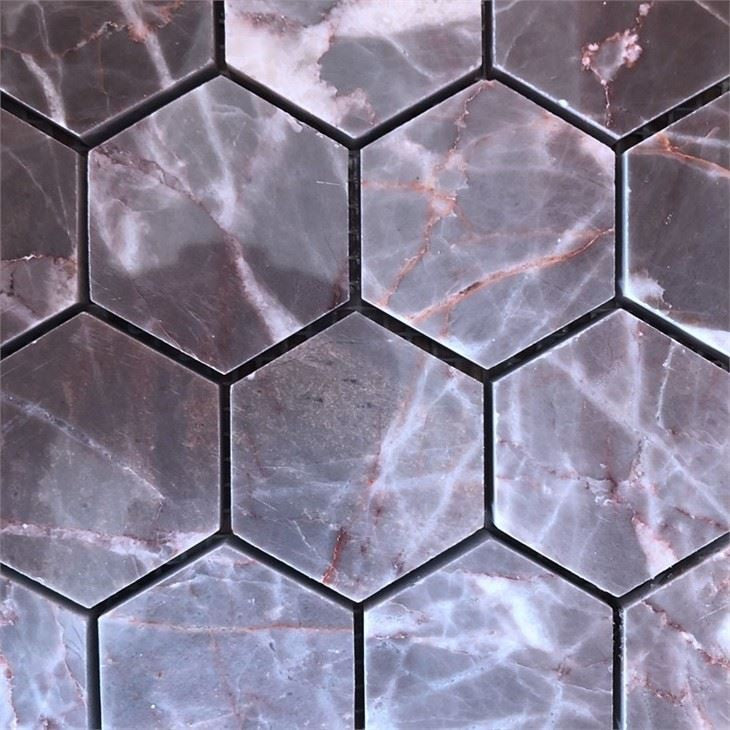

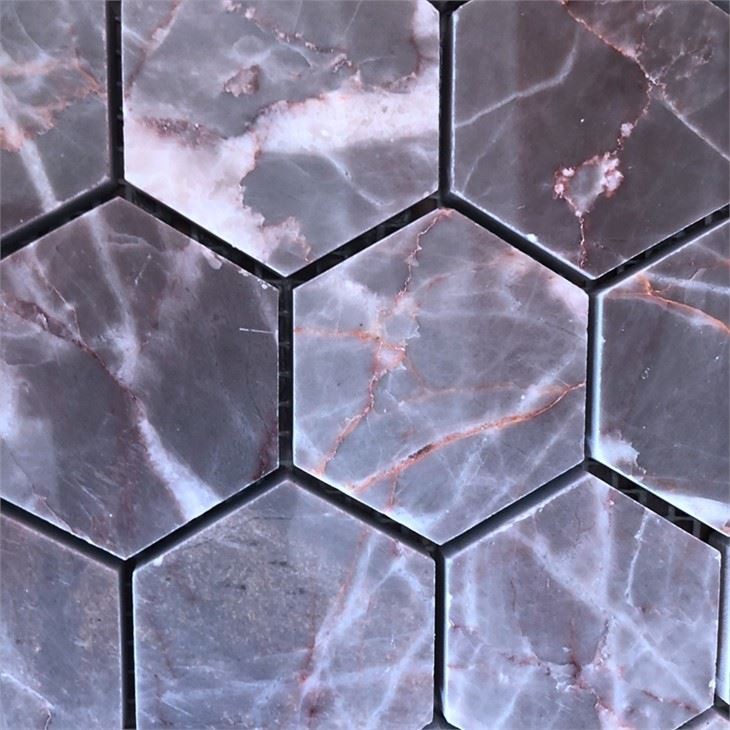

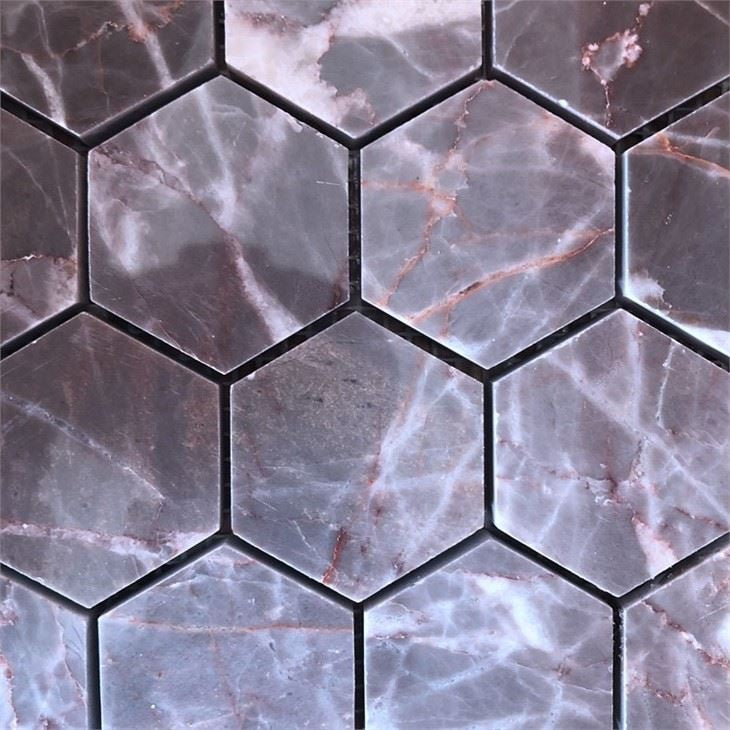

Marble Mosaic Backsplash Gray

Marble Mosaic Backsplash Gray

Enhance your kitchen or bathroom with our Marble Mosaic Backsplash in Gray. Made with high-quality marble, this elegant backsplash adds a touch of sophistication and durability to any space. With easy installation and low maintenance, it's the perfect choice for a lasting and luxurious upgrade.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Product Material | Marble |

| Surface Choice | Polished, Honed, Flamed, Antique, Stripped, Bush-hammered, Picked, Sawn, Sandblasted, Tumbled, Brushed, Rough, Lined, Acid-wash, etc. |

| Products Choice | Dry-hangs, Cut-to-Sizes, Panels, Slabs, Tops, Sanitary, Blocks, Stair Steps, Paving, Curbs, Columns, Pillars, Swimming Pool Borders, Tombstone, Sculptures, Fountains, Lanterns, Pots, Tables & Chairs, Meshed Paving, Mosaics etc. |

| Mosaics | 305x305Size(mm) |

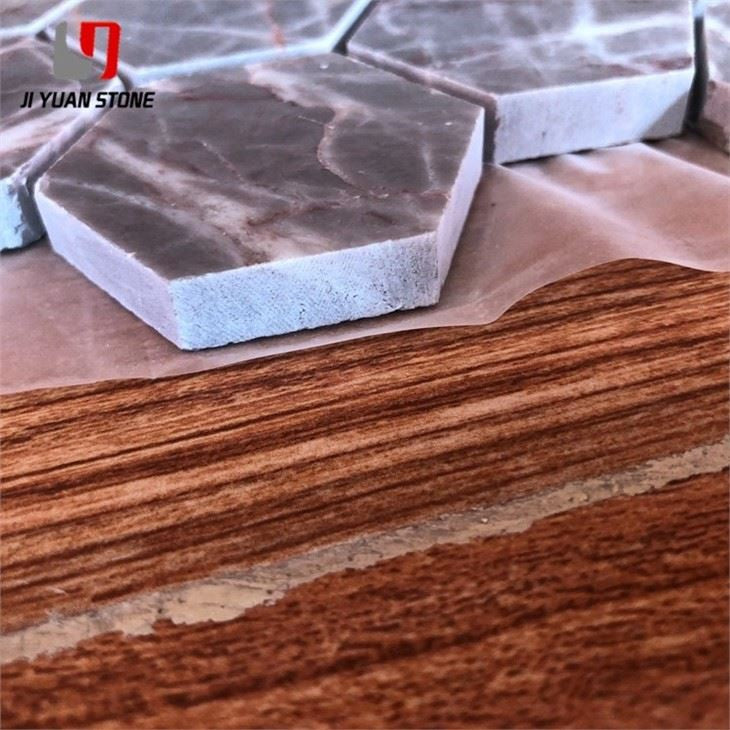

| Thickness(mm) | 10-20 |

| Package | (Poly) Wooden Crate, Pallet, Rain Cloth, Carton & Foam are Our Usual Packing Material, But Different Product Different Pack, Different Pack Different Cost. |

Marble Mosaic Backsplash Gray: Thickened Side Construction Node

Application Areas:

- Stair treads

- Sink tops

- Other countertop surfaces

Key Considerations:

- To ensure color consistency and a seamless look, the thickened bar and countertop should be cut from the same material.

- Cutting should be done from the back up, ensuring that the back sides are pasted together for a tight and secure joint.

Marble Mosaic Backsplash Gray: External Angle Edging & Chamfering Construction Node

Scope of Application:

- Indoor marble mosaic backsplash gray flooring

Important Guidelines:

1. Water Pipe Inspection

- Ensure each edging head’s water pipe is unblocked. If blocked, clear it immediately.

2. Edging Wheel Maintenance

- Regularly check the consumption of edging wheels. Replace them as needed, using the original specifications and models.

- Adjust to a reasonable feed position after replacing.

3. Measurement & Precision

- Measure every 15 minutes to maintain accuracy.

- If the size starts deviating from the normal range, adjust immediately.

4. Surface Smoothness

- Frequently check the smoothness of the edging.

- If issues arise, adjust the resin trimming wheel accordingly.

5. Chamfering Accuracy

- Ensure uniform chamfer sizes by checking regularly.

- If any irregularities are found, adjust:

- Cylinder pressure of the chamfering machine

- Angle of the chamfering seat

- Position of the electric eye

- Chamfering delay settings

6. Brick Alignment

- Check the diagonal and right-angle accuracy of the finished bricks.

- If discrepancies are found, make adjustments and notify relevant personnel if needed.

7. Cleanliness & Handover

- Before handing over, ensure all premises and equipment within the work area are thoroughly cleaned.

Share