Limestone Outdoor Pavers

Limestone Outdoor Pavers

Limestone Outdoor Pavers – Natural Elegance for Long-Lasting Outdoor Spaces

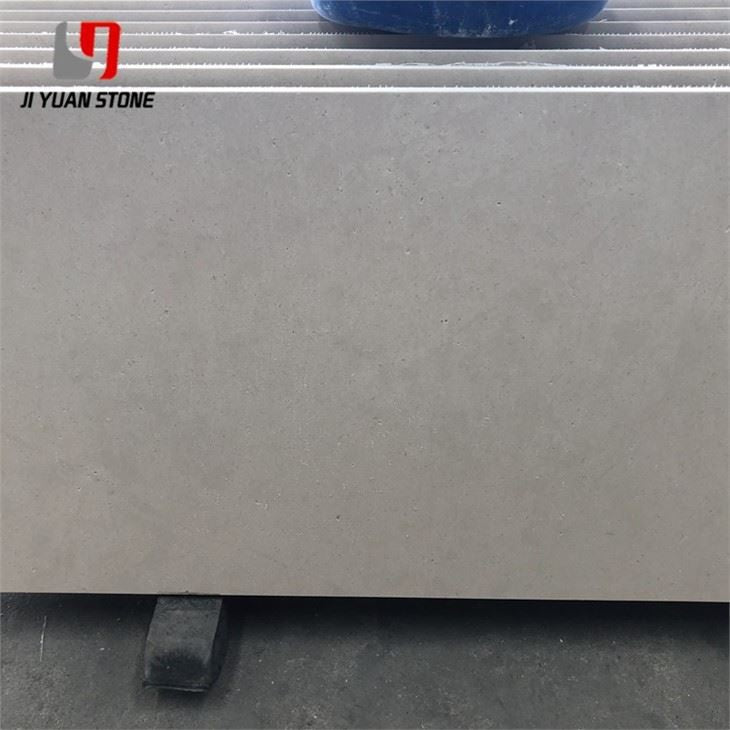

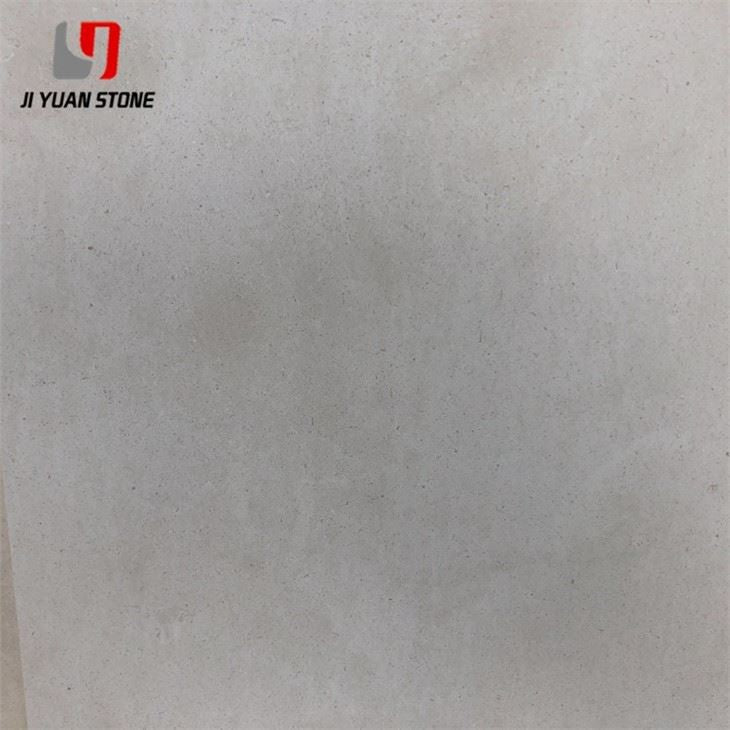

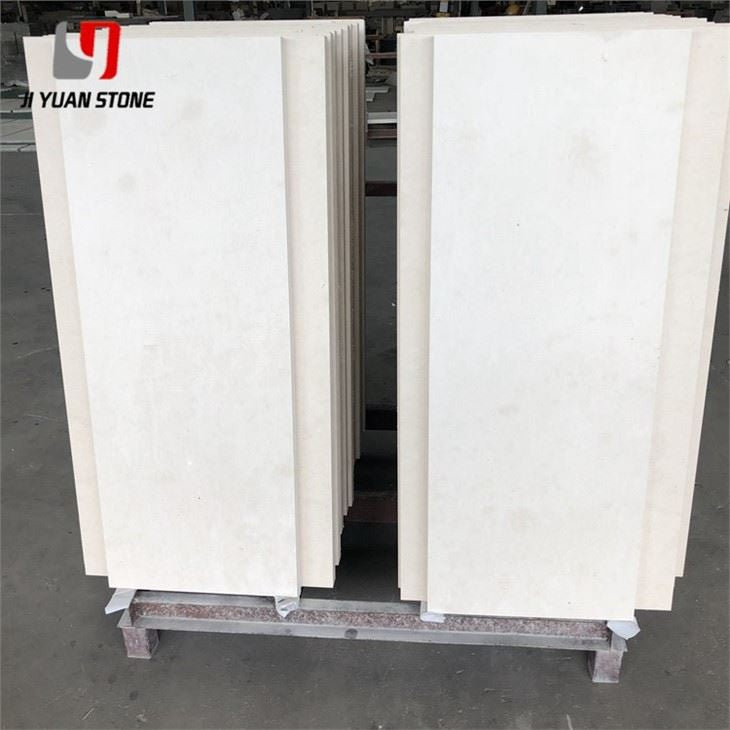

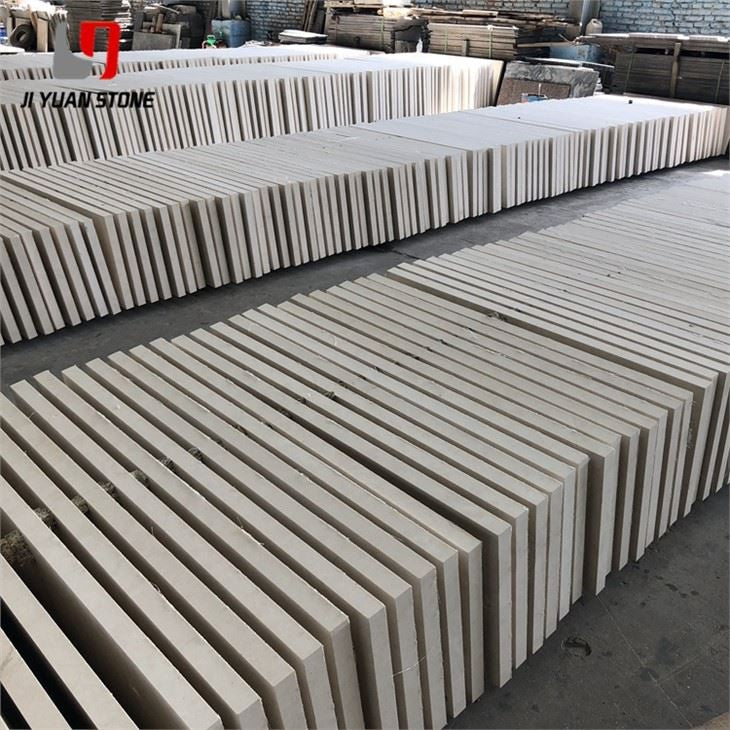

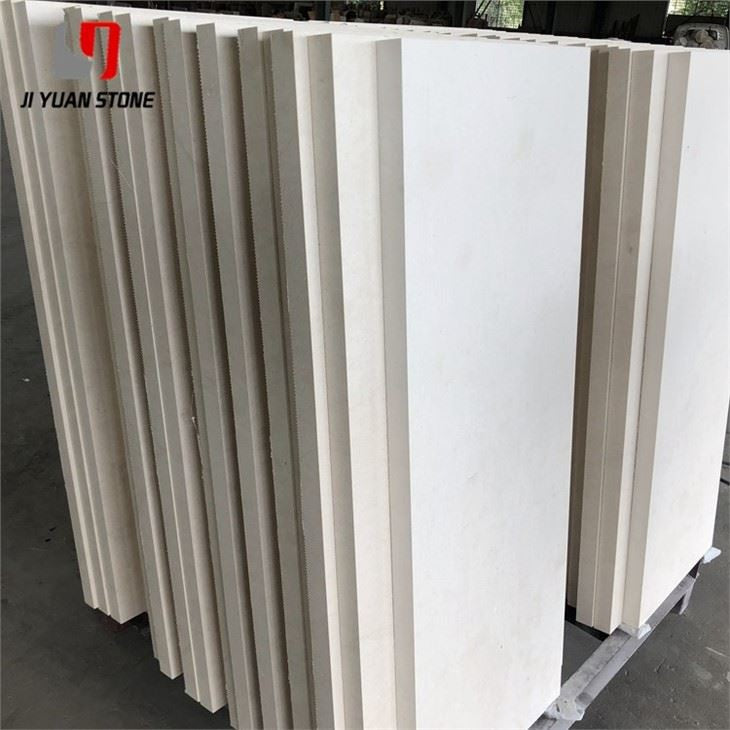

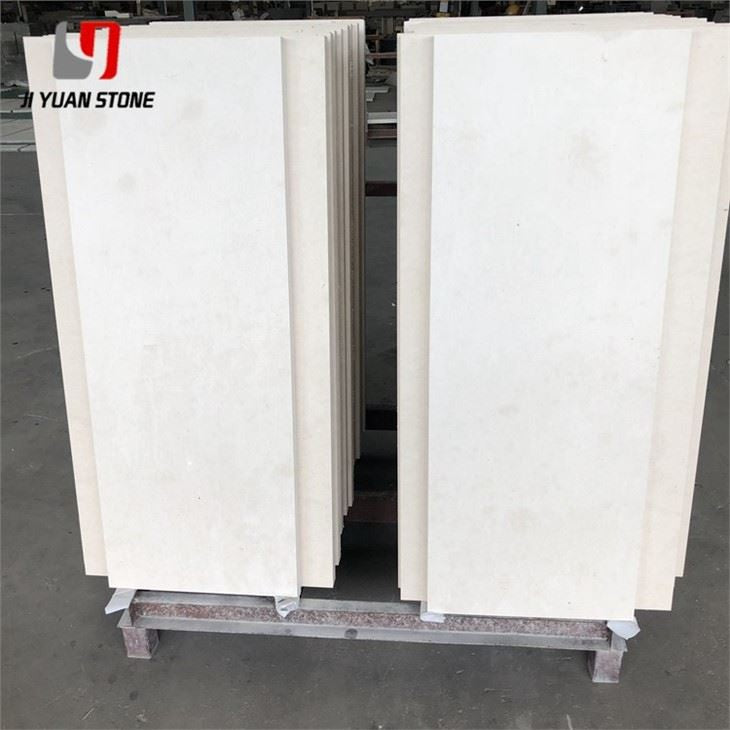

Introducing our Limestone Outdoor Pavers - a durable and stylish addition to your outdoor space. Made from natural limestone, these pavers provide a slip-resistant surface and are easy to maintain. Add unique charm to your patio, walkway, or pool area with these versatile pavers.

| Feature | Details |

|---|---|

| Matrials | limestone |

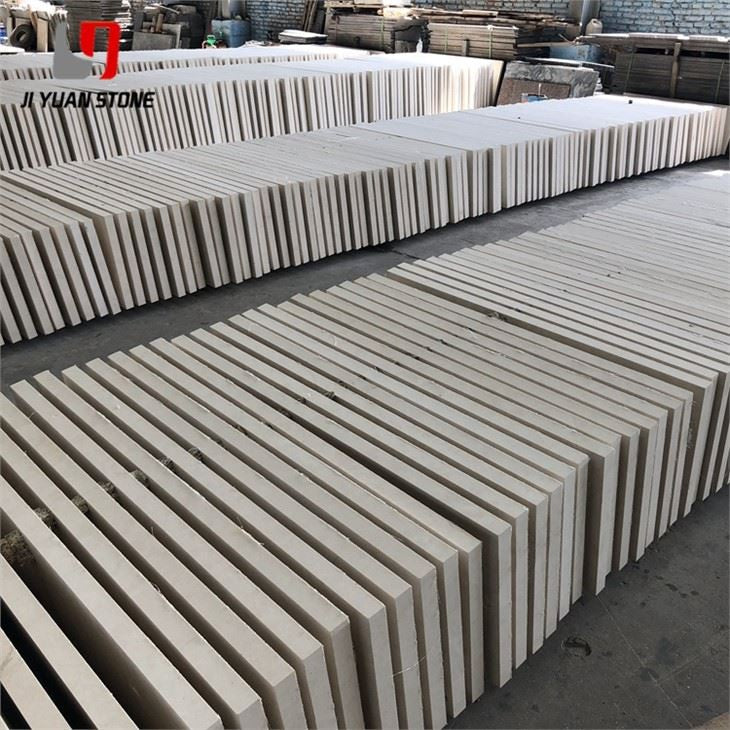

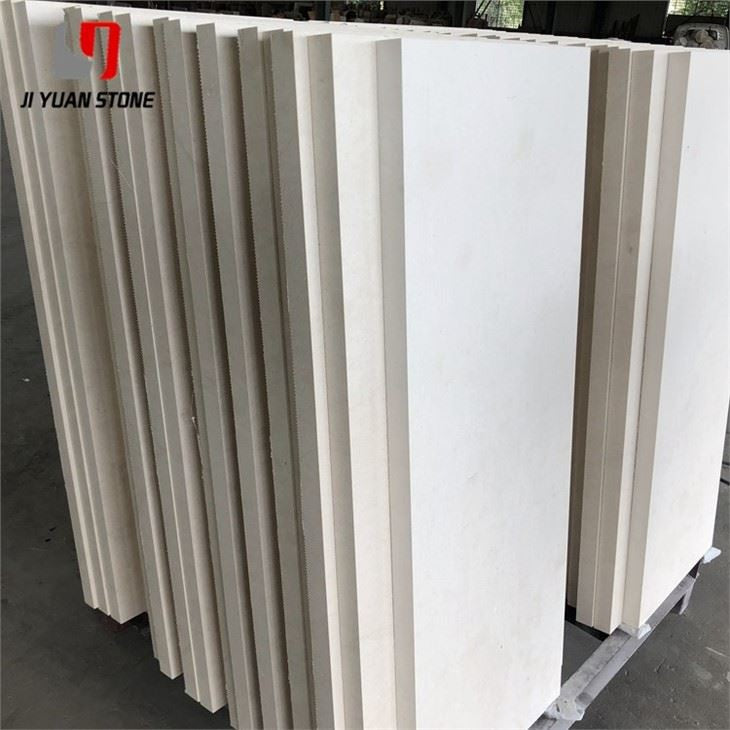

| Tiles Sizes available | 600x600mm, 800x800mm,3000x(600-1000)mm,customized |

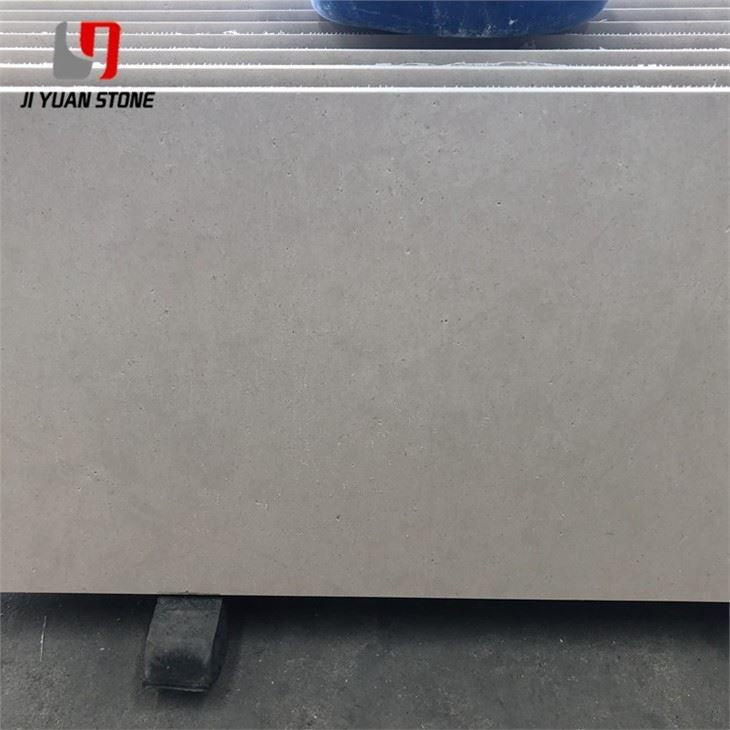

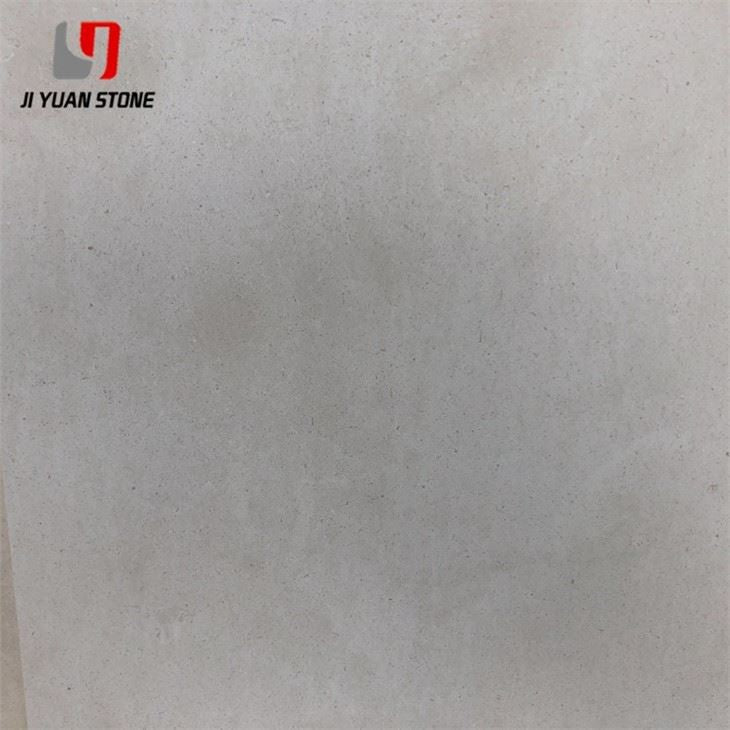

| Surface | Honed |

| Usage | Exterior wall cladding,flooring |

| Packing | Seaworthy wooden crate, pallet |

| Payment terms | 30% by T/T in advance, balance by T/T before shipment |

Limestone outdoor pavers are a beautiful, timeless solution for exterior design that blends natural elegance with geological history. Formed over millions of years from sea shells and marine bones that settled on ancient ocean floors, limestone is classified as a sedimentary stone—also known as soft marble.

The transformation occurs when calcium from the bones and shells reacts with carbon dioxide in seawater, producing calcium carbonate—the mineral backbone of all limestone and marble formations. The result is a chalky, smooth natural stone often embedded with visible fossils, offering exceptional visual texture and a sense of tranquility wherever it's placed.

🪨 Why Choose Limestone Outdoor Pavers?

✔ Natural Beauty – Smooth surface with earthy tones and fossil patterns

✔ Durable & Versatile – Ideal for patios, walkways, garden paths, and pool surrounds

✔ Cool Underfoot – Great for warm climates

✔ Refined Yet Rustic – Perfect for both traditional and modern outdoor aesthetics

✔ Highly Functional – Used in various industries beyond construction

⚙️ Applications & Industrial Significance

In addition to architectural use, limestone outdoor pavers are widely employed in several industries due to their versatile composition:

- Building Materials – Used in Portland cement and other construction-grade products

- Paper & Coatings – Source of heavy calcium carbonate for high-end paper and paint finishes

- Plastic & Coating Fillers – Acts as a functional filler in manufacturing

- Foundry Sand – Ideal in machine casting and industrial applications

🏗️ Processing of Limestone Outdoor Pavers

The limestone paver production process combines natural stone preparation with advanced technology:

1 . Crushing & Sizing:

Bulk limestone is crushed to the required size using high-efficiency crushers.

2 . Material Elevation:

Crushed material is transported via bucket elevators into storage silos.

3 . Feeding & Grinding:

An electromagnetic vibrating feeder moves material into the grinder's cavity. Inside, shovel blades and grinding rollers rotate simultaneously, pressing the limestone between roller rings.

4 . Cushion Layer Grinding:

This action creates a compact cushion layer, allowing efficient grinding that results in high-quality fine material for paver use.

🧼 Care & Maintenance

Limestone outdoor pavers maintain their beauty with simple care:

- Use neutral pH cleaners to avoid etching

- Seal periodically to protect against moisture and stains

- Rinse off abrasive debris (like sand or gravel) to prevent scratching

- Avoid acidic or harsh chemical agents

Conclusion

With its rich fossil history, elegant appearance, and strong performance across applications, limestone outdoor pavers are a top-tier choice for landscape designers, architects, and homeowners seeking a material that offers both beauty and practicality.

Whether you're crafting a cozy garden path, a grand patio, or a rustic courtyard, limestone pavers deliver enduring charm rooted in nature’s most fascinating formations.

Enhance your outdoor space with the timeless appeal of limestone outdoor pavers – where natural beauty meets engineered performance.

Share