Limestone Floor Tiles

Limestone Floor Tiles

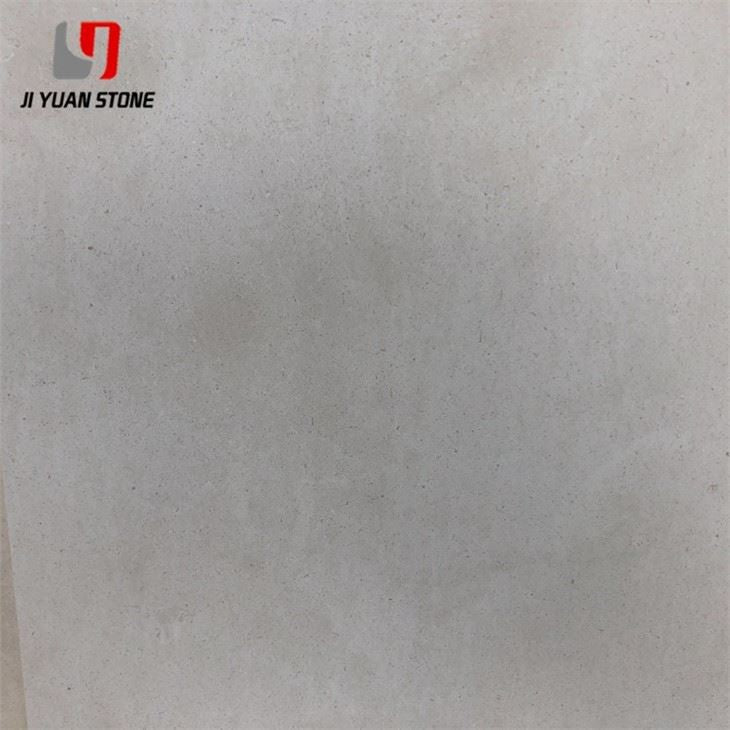

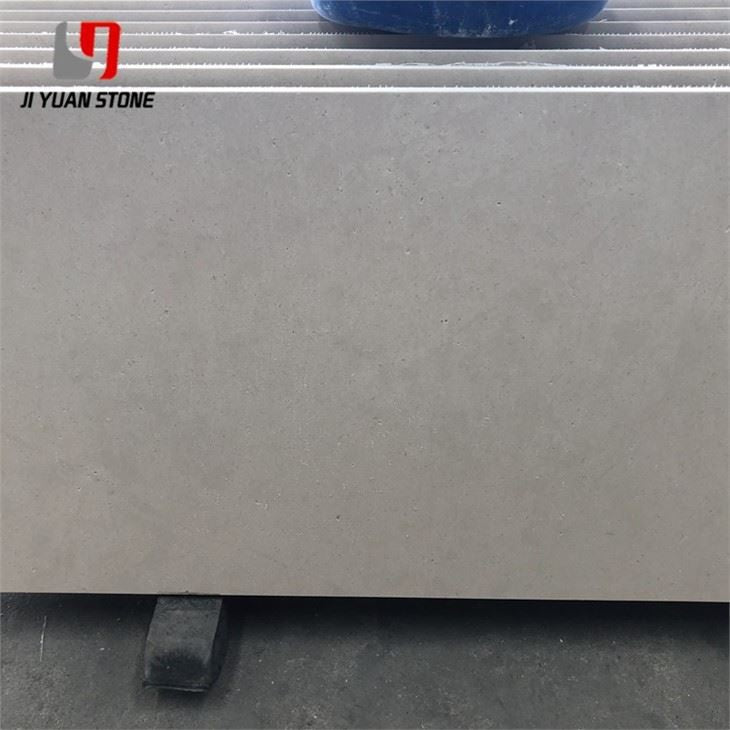

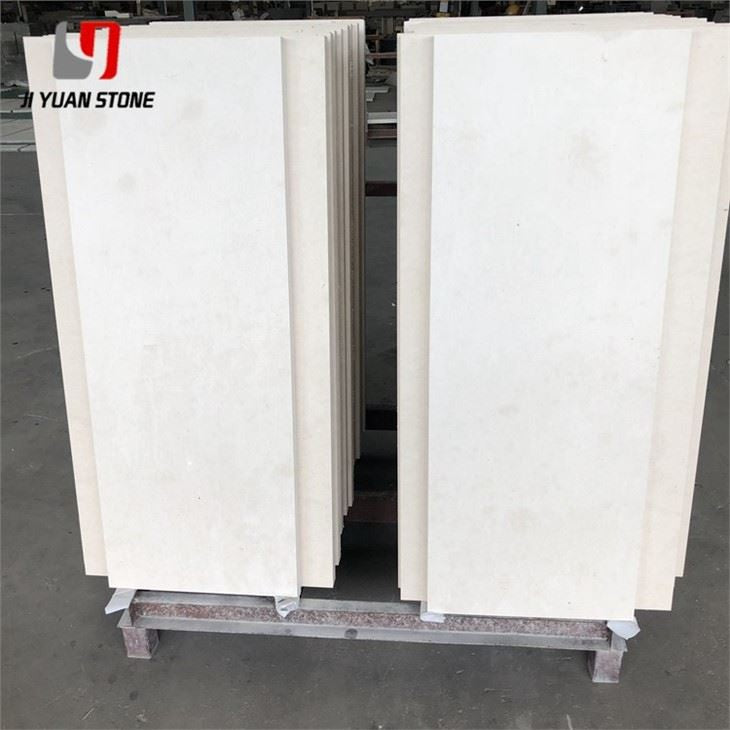

Limestone Floor Tiles – Timeless Beauty with Advanced Waterproof & Anti-Stain Technology

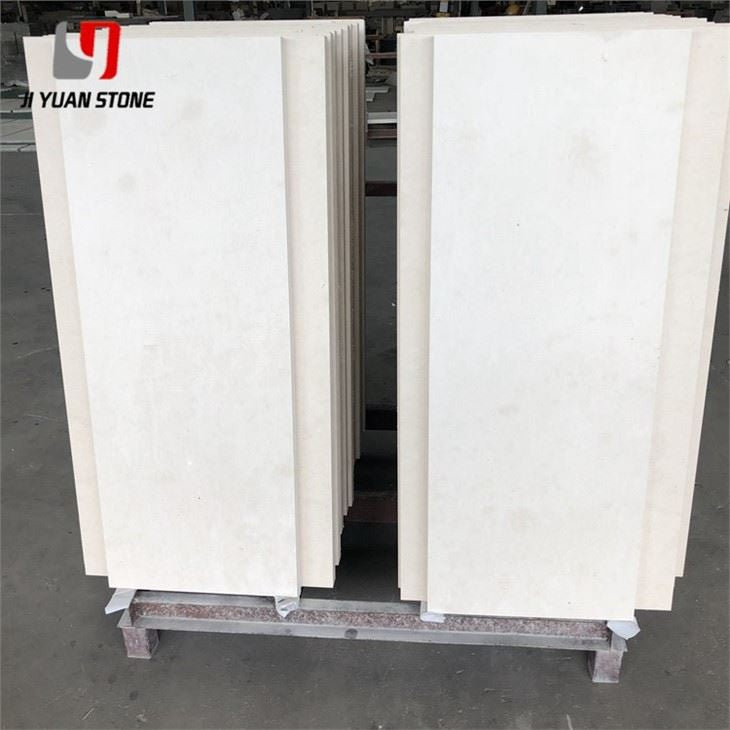

Discover the timeless beauty and durability of Limestone Floor Tiles. These natural stone tiles are perfect for any room in your home, providing both style and practicality. With their unique patterns and textures, they add a touch of luxury to your space while being easy to maintain. Elevate your flooring with Limestone Floor Tiles.

| Feature | Details |

|---|---|

| Matrials | limestone |

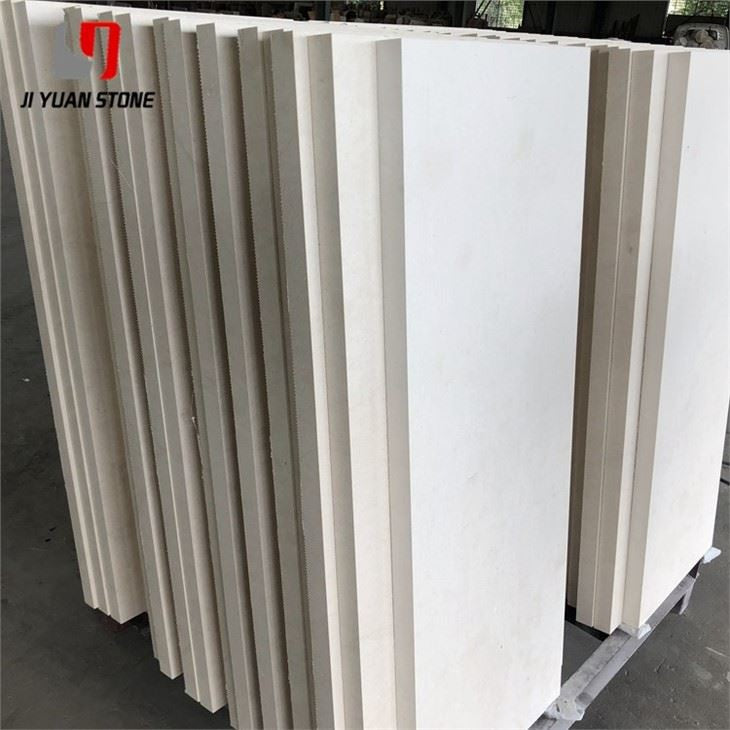

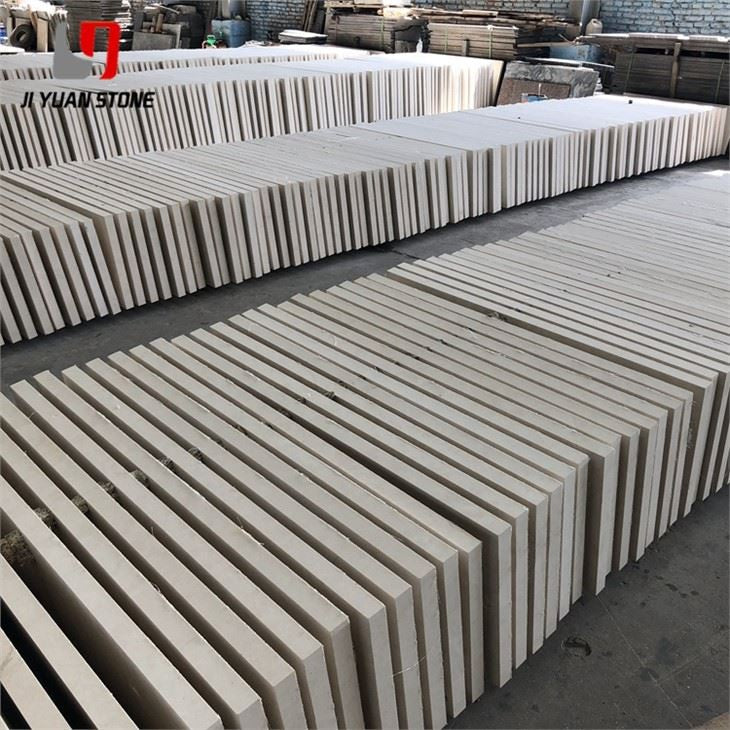

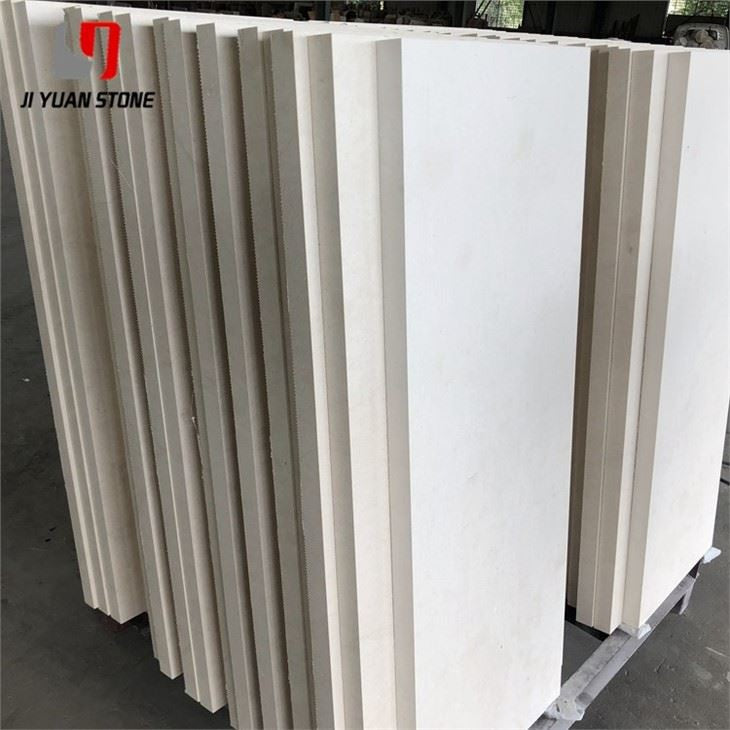

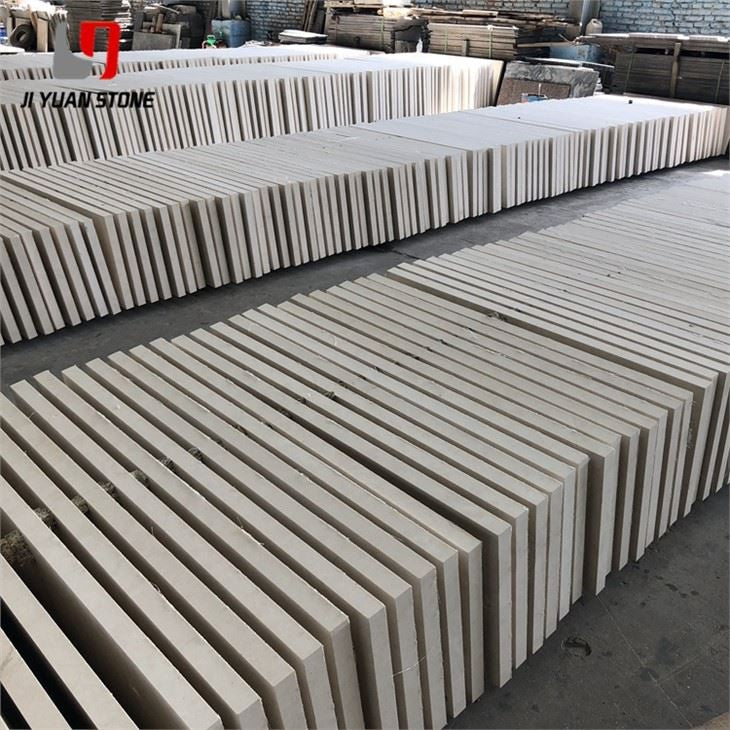

| Tiles Sizes available | 600x600mm, 800x800mm,3000x(600-1000)mm,customized |

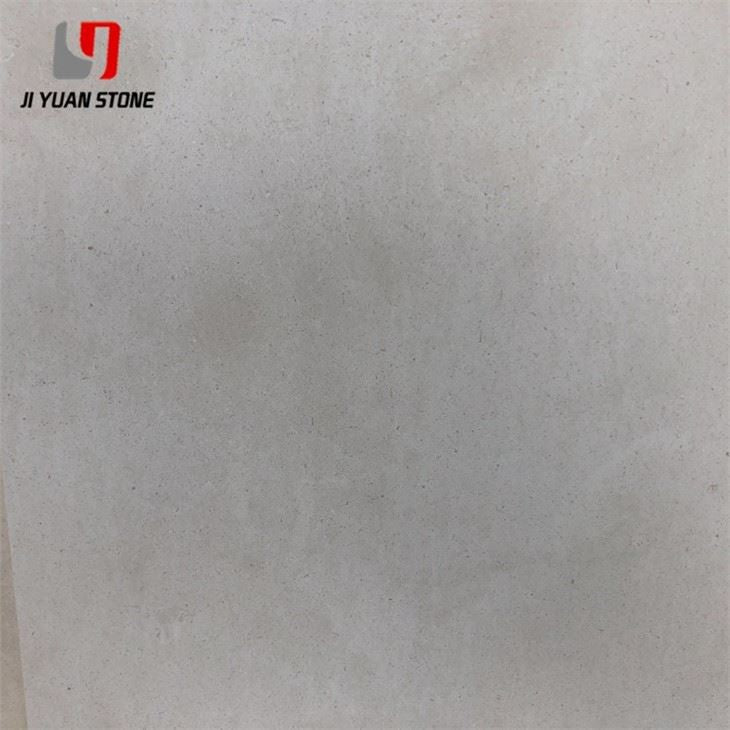

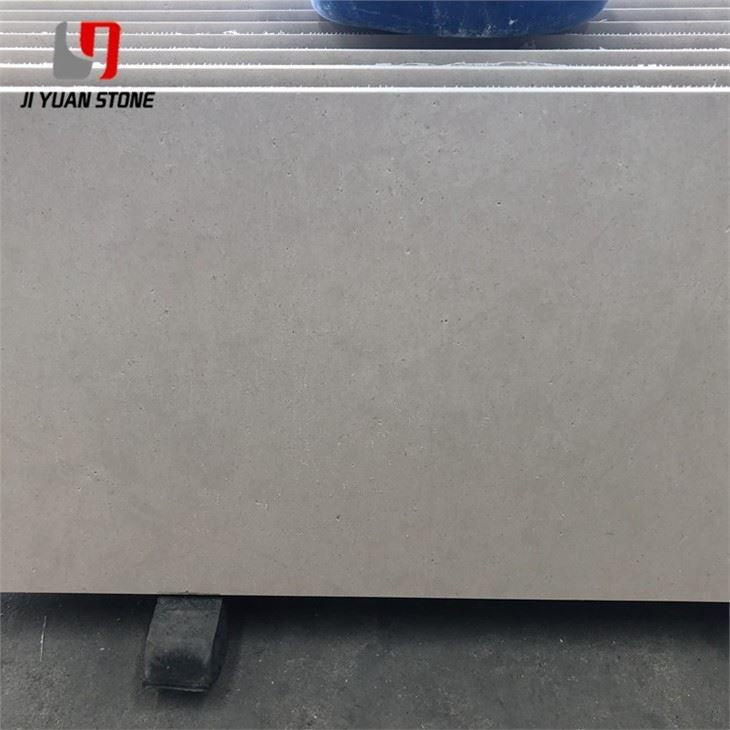

| Surface | Honed |

| Usage | Exterior wall cladding,flooring |

| Packing | Seaworthy wooden crate, pallet |

| Payment terms | 30% by T/T in advance, balance by T/T before shipment |

Limestone floor tiles are a perfect fusion of natural elegance and modern stone treatment technology. Formed over millions of years from marine shell and skeletal deposits, limestone is a sedimentary stone, commonly known as soft marble. Its base composition—calcium carbonate formed by the reaction of bone and shell matter with carbon dioxide in ocean waters—creates a smooth, chalky stone often containing visible fossils, offering a unique visual texture and serene ambiance.

But natural beauty is just the beginning.

💧 Advanced Protection for Longevity and Cleanliness

Thanks to cutting-edge stone treatment processes, our limestone floor tiles are now engineered to perform better than ever. The key is in the silica (SiO₂) cubic crystal deposition technology, which seals the stone’s pores, blocking dust, liquids, and stains from penetrating.

Here’s how it works:

- Silicifying agents are applied to deeply saturate the pores of the stone.

- SiO₂ crystals form within the pores, dramatically reducing water absorption and increasing anti-fouling resistance.

- After treatment, a fluorine-based stone protector is applied to lock in moisture resistance and long-term surface cleanliness.

💡 Tested & Proven: Even after 2 hours of exposure to carbon black ink, the treated limestone surface washed clean without any staining. In contrast, untreated tiles retained obvious marks.

🛠 Limestone Tile Protection – Construction Plan Overview

For the best water and stain resistance, limestone floor tiles undergo the following multi-step protective treatment:

1 . Surface Cleaning – Remove dust, grease, and contaminants from slabs or tiles.

2 . Drying – Ensure maximum dryness for deeper silicifier absorption.

3 . Silicifier Application – Repeatedly apply until absorption rate slows.

4 . Drying & Curing – Ventilate until original color is restored; bake at 60–100°C for optimal results.

5 . Fluorine-Based Protection – Apply high-grade fluorine sealer for ultimate protection.

6 . Quality Inspection & Factory Dispatch – Tiles are shipped only after passing stringent quality tests.

🌟 Key Benefits of Our Treated Limestone Floor Tiles

- Natural Appearance: Earthy tones, soft veining, and fossilized textures.

- Superior Stain Resistance: Perfect for kitchens, bathrooms, lobbies, and high-traffic areas.

- Low Water Absorption: Greatly enhanced through silicifier treatment and sealing.

- Easy Maintenance: Simple to clean, no deep staining, no special detergents needed.

- Long-Term Performance: Maintains beauty and integrity for decades.

- Versatile Design: Suitable for both traditional and contemporary interiors.

🏠 Applications

- Residential flooring

- Commercial lobbies

- Hotel and spa interiors

- Museums and heritage buildings

- Kitchen and bathroom floors

- Covered patios and terraces

Conclusion

Limestone floor tiles not only bring timeless natural aesthetics but also now offer superior durability and stain resistance. Whether you’re building a modern space or restoring a classic interior, our treated limestone flooring provides beauty, performance, and peace of mind—sealed, protected, and ready to last.

Invest in Limestone Floor Tiles – Naturally Elegant, Technically Advanced.

Share