Light Travertine Tumbled Wall Tile

Light Travertine Tumbled Wall Tile

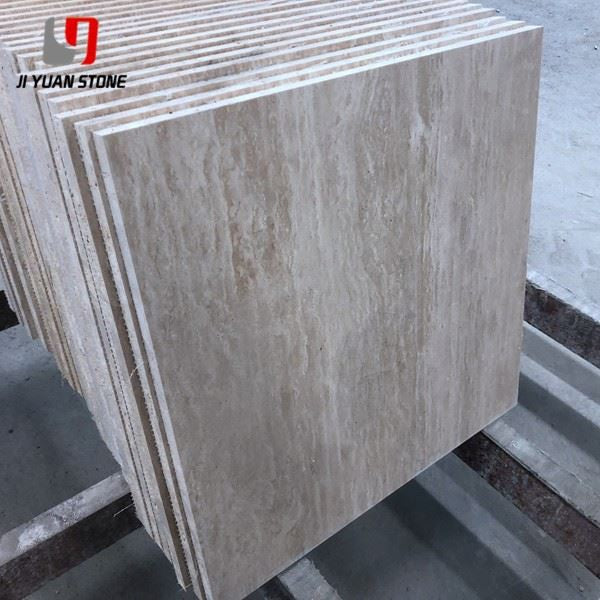

Light Travertine Tumbled Wall Tile – Rustic Beauty Meets Natural Strength

Enhance your home with our Light Travertine Tumbled Wall Tile. Made with high-quality travertine, this tile is both durable and stylish. The tumbled finish adds a unique texture and warmth to any space. Experience the timeless beauty of natural stone with this versatile wall tile.

| Feature | Details |

|---|---|

| Product Name | Light Travertine Tumbled Wall Tile |

| Material | Natural Light Travertine Marble Stone Slabs and Tiles |

| Colour | Black, White,Grey, Silver,Red, Yellow,Ivory White, Beige etc |

| Thickness | 1mm,8mm,10mm,15mm,18mm,20mm etc |

| Usage | Pool coping,pavers,floor tile,wall panel,countertop,table etc |

Bring warmth and timeless charm to your space with Light Travertine Tumbled Wall Tile. With its soft beige hues, textured finish, and classic character, this natural stone is perfect for kitchen backsplashes, bathroom walls, fireplace surrounds, and feature walls in living spaces.

Crafted from premium travertine and tumbled for a weathered, antique look, these tiles offer both durability and elegance, enhancing any interior style—from modern minimalist to rustic Mediterranean.

🌍 Global Stone Solutions You Can Trust

Our Stone Variety covers 80% of the world, expertly processed into:

- Tiles & slabs

- Countertop & vanity tops

- Tub surrounds, shower panels, soap dishes

- Fireplaces, sculptures, mosaics, medallions

- Paving stone, cobblestone

- All kinds of custom natural stone products

🛠️ We Also Provide Matching Accessories:

To complete your kitchen or bathroom project, we offer coordinated accessories to match your granite and marble countertops:

- Stainless Steel Sinks (304 material, 18 Gauge)

- Ceramic Under-Mount & Drop-In Sinks

- Faucets (4" or 8")

- PVC & Wooden Cabinets for kitchen and bathroom use

We proudly supply products to over 120 countries, and our 6,000 sq. ft. showroom allows you to view and select your materials directly.

🧱 Installation Guidelines for Light Travertine Tumbled Wall Tile

1. Adhesive Mixing & Surface Preparation

- Use clean tap water only when mixing adhesives.

- Do not add any other substances or additives.

- Apply slurry within 2 hours of mixing.

- Avoid generic protectants—use AD2009 waterproof adhesive for superior bonding and stain prevention.

2. Dry Hanging Installation – Slotted Method (Seam Type)

This method uses a grooved slot on the top and bottom of each stone, secured with a T-plate and glue. While commonly used, there are important considerations:

⚠️ Limitations of Slotted Dry Hanging:

- Weak shock resistance: prone to cracking with vibration.

- Low flexibility: can't accommodate structural movement.

- Requires ≥20mm thickness for safe load-bearing.

- Increased pressure as height of installation increases.

- Removal and repositioning are difficult post-installation.

💡 Updated Standard (JGJ133):

For enhanced safety, L-type single-sided fasteners are now recommended, replacing older T-type mounts. Each tile is individually attached to a metal support frame, improving load distribution and seismic performance.

🌟 Why Choose Light Travertine Tumbled Wall Tile?

✅ Textured rustic finish with soft natural color tones

✅ Ideal for backsplashes, showers, fireplaces & more

✅ Durable & moisture-resistant for long-term performance

✅ Natural elegance for any decor theme

✅ Globally trusted sourcing & quality

Add character and warmth to your interior with Light Travertine Tumbled Wall Tile—a timeless stone solution for elegant, natural, and maintenance-friendly living.

Share