Ledgstone Wall Slate

Ledgstone Wall Slate

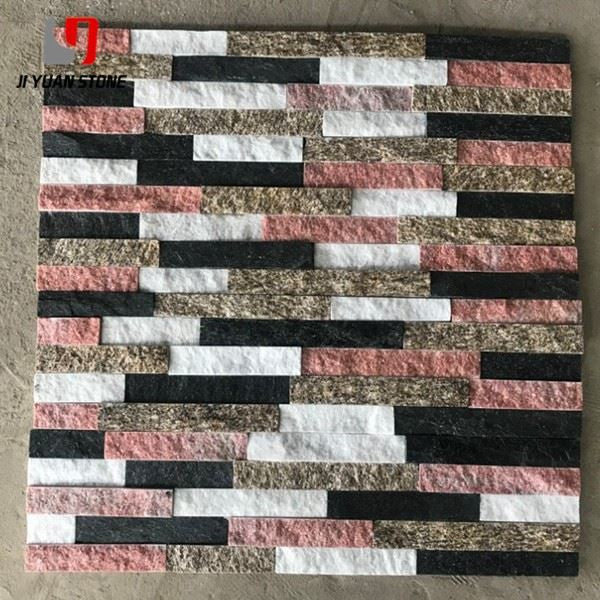

Ledgestone Wall Slate – Natural Elegance Meets Structural Integrity

Enhance the aesthetics of your home or business with Ledgestone Wall Slate. This premium slate offers durability and beauty, with its unique textures and patterns. Made of high-quality materials, it is perfect for indoor and outdoor use. Transform any space into a stunning showcase with Ledgestone Wall Slate.

| Feature | Details |

|---|---|

| Product | Ledgstone Wall Slate |

| Surface | Split face |

| Thickness | 0.8-1.2cm,1-1.5cm,1-2cm,1.5-2.5cm,2.5-3.5cm etc |

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, stairs, steps, wall panel, flooring, veneers, slabs, coping tiles, bathtub etc |

| Colour | Black, Blue, White, Red, Pink, Brown, Yellow, Grey, Green, Purple, etc. |

| Material | Granite, Marble, Quartz, Sandstone, Basalt, Slate, Travertine etc |

| Products | Available in Slabs, Tiles, and customized sizes.ect |

| Application | Outdoor and indoor construction projects; |

| Sizes | Available in different sizes for different products; Customized specification is also available. |

| Thickness (cm) | 1, 1.2, 1.5, 1.8, 2, 3, etc |

| Slabs (cm) | 60x120up, 70x120up,120upx240up,etc |

| Tiles (cm) | 30x30,60x60,30x60,305x305,etc |

| Edge | Bevel, Flat, Bullnose, Cut, etc |

| Finish | Polished, Honed, Flamed, Bushhammered, etc |

| Package | International Seaworthy wooden crates; available with Customized packing requirements |

Transform your spaces with our premium Ledgestone Wall Slate, a versatile natural stone cladding solution perfect for both interior and exterior applications. Crafted from high-quality slate, these ledgestone panels offer a timeless aesthetic, combining rustic charm with modern sophistication.

🛠️ Installation Methods: Dry Hanging vs. Wet Pasting

Choosing the right installation method is crucial for the longevity and appearance of your stone cladding. Here's a comparison to help you decide:

| Method | Advantages | Disadvantages |

|---|---|---|

| Dry Hanging | ✅ Excellent freeze-thaw resistance<br>✅ No alkali return<br>✅ Strong shock resistance | ❌ Increases building load due to additional materials<br>❌ Total thickness after construction is at least 150mm, consuming space<br>❌ High cost |

| Wet Pasting | ✅ Total thickness is only 40-50mm, saving space<br>✅ Lower cost | ❌ Poor freeze-thaw resistance<br>❌ Prone to alkali return<br>❌ Weak earthquake resistance |

Dry hanging is typically used outdoors and in high-end, large-area spaces such as lobbies and halls. Wet pasting is commonly used in indoor spaces like bathrooms, where cost savings and space efficiency are priorities.

For furniture with ledgestone wall slate veneer, dry sticking (using two-component adhesive) is preferred due to its convenience, affordability, and space-saving benefits. However, it is not suitable for large-scale construction. For tall walls (above 2m) and large ledgestone wall slate layouts, dry hanging is the most suitable method.

⚠️ Common Installation Challenges & Control Measures

Challenges:

- Non-standard adhesive usage: Some adhesives have a high deformation coefficient, leading to instability.

- Thick-layer application: Traditional single-side scraping results in a thick adhesive layer of 3-4 cm, which is inefficient.

- Dense seam splicing: If stone slabs are installed without expansion joints, cracks and stress issues may arise.

Control Measures:

Use high-quality adhesives: Choose C1-level adhesives or higher to meet the strength requirements for wall stone paving.

Adopt double-sided thin-layer paving:

- Apply adhesive on both the wall and the ledgestone wall slate.

- Fully knead and press the stone to ensure 100% adhesion.

- Keep the adhesive layer thickness within 2 cm.

Proper joint spacing:

- Flexible caulking agents should be used for lightweight partition walls.

- Expansion joints must be reserved for large-area installations to prevent cracking.

- Natural Aesthetic: Each panel showcases the unique textures and colors of natural slate, adding character to any space.

- Durability: Resistant to weathering, making it suitable for both indoor and outdoor applications.

- Versatility: Ideal for feature walls, fireplaces, facades, and more.

- Easy Installation: Designed for straightforward installation, whether you choose dry hanging or wet pasting methods.

- Material: Natural Slate

- Panel Size: Typically 6" x 24" (custom sizes available upon request)

- Thickness: Varies between 1.5 cm to 3 cm

- Finish: Natural split face for a rugged texture

- Color Options: Available in a range of natural hues to suit various design preferencesledgerpanels.com

- Regular Cleaning: Use a soft brush or cloth to remove dust and debris.

- Avoid Harsh Chemicals: Clean with pH-neutral cleaners to preserve the stone's natural appearance.

- Sealant Application: Apply a high-quality stone sealant periodically to protect against stains and moisture.

Share