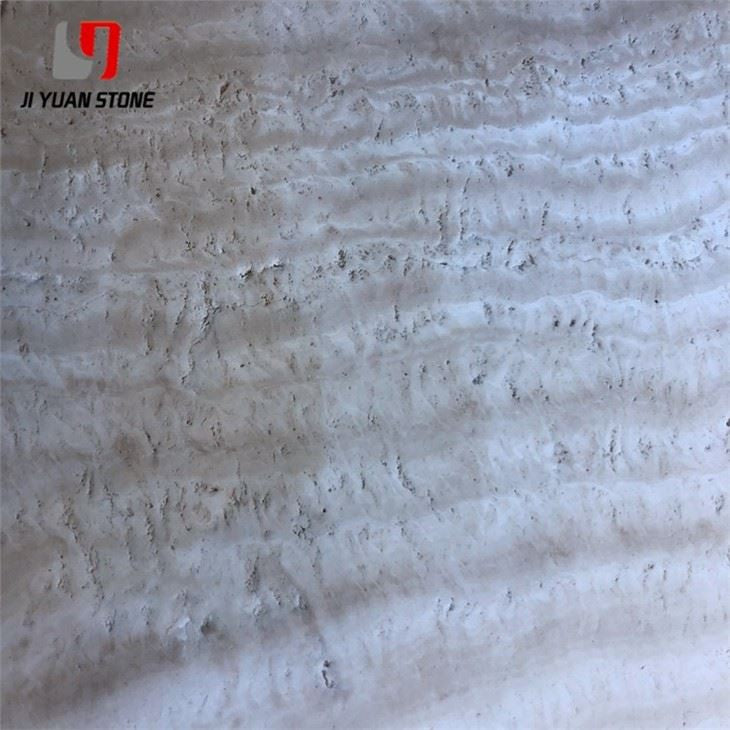

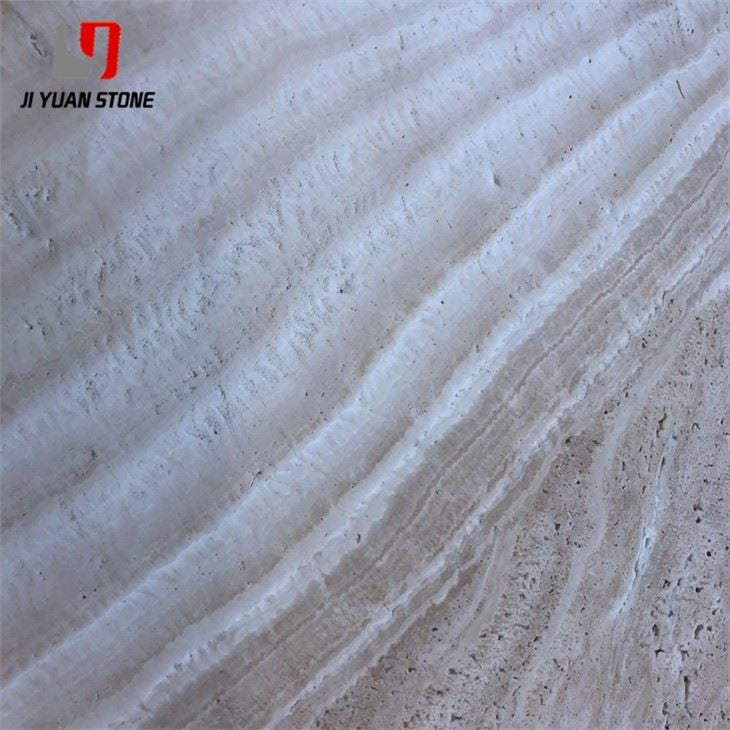

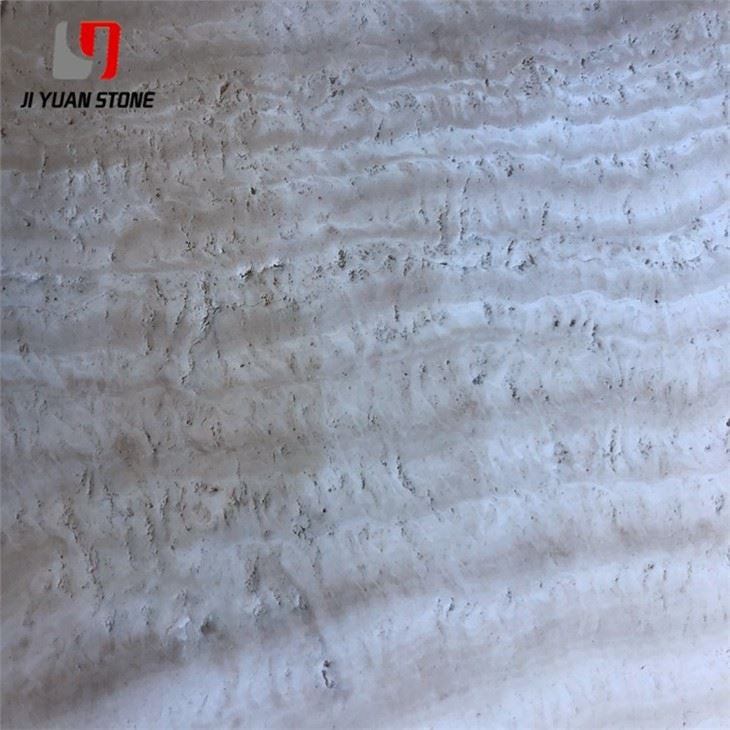

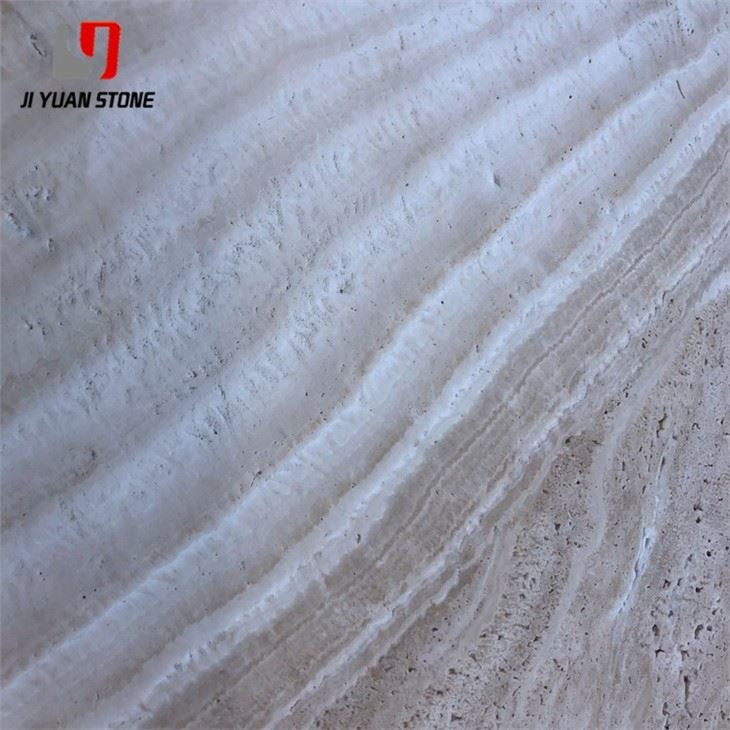

Ivory Travertine Tumbled Tile

Ivory Travertine Tumbled Tile

Ivory Travertine Tumbled Tile – Classic Elegance with Rustic Charm

Introduce a touch of luxury with our Ivory Travertine Tumbled Tile. Made from beautiful ivory travertine stone, this tile adds a timeless elegance to any space. The tumbled finish adds texture and character, while the natural tones and patterns create a warm and inviting atmosphere. Elevate your home with the natural beauty of our Ivory Travertine Tumbled Tile.

Ivory Travertine Tumbled Tile is a premium natural stone choice that beautifully blends rustic texture with timeless luxury. With its soft ivory hues, antique surface finish, and subtle porous character, this limestone tile adds depth and warmth to both modern and traditional interiors. It is especially ideal for floors, walls, bathrooms, patios, and outdoor kitchens.

Perfectly suited for high-end homes, villas, spas, and commercial spaces, tumbled travertine tiles are known for their non-slip surface, weathered look, and natural durability.

✅ Key Features of Ivory Travertine Tumbled Tile:

- 🪨 Natural Stone Material – Formed from high-quality ivory travertine, a type of limestone with a beautiful porous texture.

- 🎨 Tumbled Finish – A gently aged look with softened edges for a warm, antique appeal.

- 🌧️ Water-Resistant with Proper Treatment – Highly absorbent by nature, but easily waterproofed for long-term durability.

- 🛠️ Indoor & Outdoor Use – Ideal for bathrooms, backsplashes, pool decks, courtyards, garden paths, and more.

✅ Waterproofing & Handling Tips:

Due to its natural porosity, ivory travertine tumbled tile requires proper waterproofing to maintain its performance and beauty, especially in high-moisture areas.

🔹 1. Waterproofing Treatment

- Apply breathable, non-film-forming organic fluorine or silicon-based sealants.

- For glued seams: waterproof the outer surface only.

- For open seams: waterproof all six sides of the tile.

- Reapply every 3–5 years to maintain effectiveness.

- Fill any excessive surface holes before installation.

🔹 2. Back Composite Layer for Strength

Ivory travertine is naturally fragile. To avoid cracking or breakage:

- Reinforce tiles with glass fiber cloth or composite material on the back.

- This adds structural strength and enhances long-term performance.

🔹 3. Handling Unqualified or Damaged Stone

- Never install substandard tiles—they pose a serious safety hazard.

- If discovered post-installation, perform technical evaluations and apply engineering reinforcements where needed.

- If possible, always replace unqualified slabs.

✅ Travertine Marble Care Instructions:

To ensure your tumbled travertine tiles stay beautiful and intact, follow these nursing methods:

1 . Protect Against Heavy Impact:

Travertine is fragile—avoid dropping or knocking heavy objects (especially metal tools) on its surface to prevent pits and cracks.

2 . Gentle Cleaning:

Wipe with a slightly damp cloth and mild detergent.

Afterward, polish with a clean, soft cloth.

If stained, you may use weak acidic cleaners like lemon juice or vinegar, but never use harsh soaps, soda powder, or abrasive chemicals that damage the marble's integrity.

📩 To learn more about maintenance or to request bulk pricing, don’t hesitate to contact us.

✅ Reliable Quality Control:

Our comprehensive quality control system ensures every tile is:

- Checked piece by piece by our experienced QC team

- Monitored throughout every stage—from production to final packaging

- Delivered with consistent texture, color, and dimension

This guarantees both safety and satisfaction for every order, no matter the size.

✅ Product Specifications:

- Product Name: Ivory Travertine Tumbled Tile

- Material: Limestone (Travertine)

- Finish: Tumbled (Antique Look)

- Color: Ivory / Beige

- Application: Interior & Exterior Flooring, Bathrooms, Patios, Poolsides, Walls

- Features: Natural look, anti-slip surface, water-sealable, eco-friendly

- Size Options: Custom dimensions available upon request

Ivory Travertine Tumbled Tile is a versatile and timeless solution for designers and homeowners seeking natural stone charm with functional reliability. When treated and handled properly, these tiles will last decades while adding serene, rustic beauty to any space.

🛒 Order now and bring the elegance of nature into your home or project.

Share