Ivory Travertine Slab

Ivory Travertine Slab

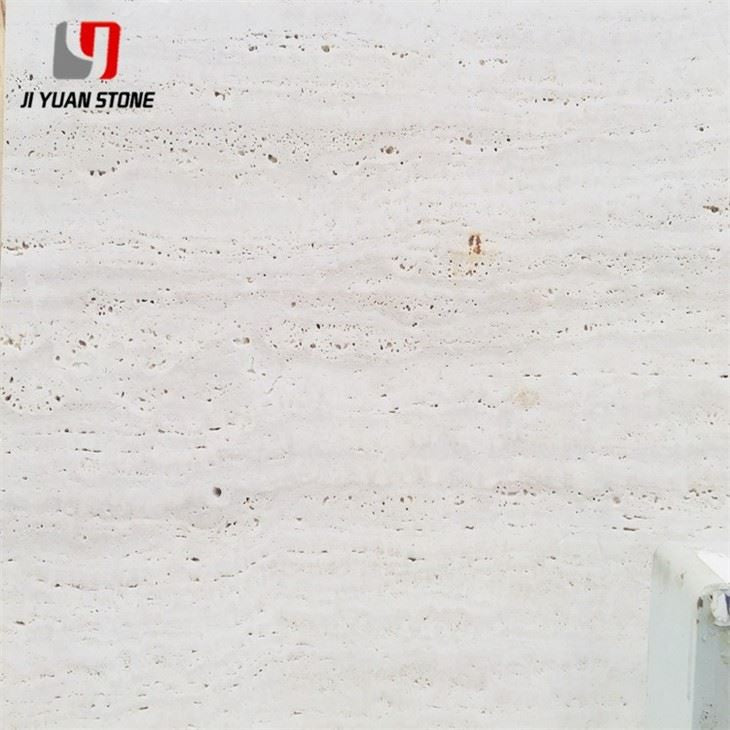

Ivory Travertine Slab – Sophisticated Natural Beauty for Timeless Spaces

Crafted from the finest quality Ivory Travertine, our slab is the perfect choice for elegant and timeless designs. With its natural beauty and durability, it's a versatile addition to any space. Use it for countertops, floors, or walls and enjoy its classic aesthetic for years to come.

| Feature | Details |

|---|---|

| Stone Type | Natural Travertine |

| Surface | Polished,Honed,Acid,Sandblasted,etc. |

| Available Size |

|

| Packing | Strong Export Fumigated Wooden Crates. |

| Usage | Indoor Wall/Floor Decoration, Bathroom, Kitchen, Living Room. |

| Quality Control |

Thickness tolerance(length, width, thickness): +/-1mm(+/-0.5mm for thin tiles) QC check pieces by pieces strictly before packing |

| MOQ | Small trial orders are welcome. |

| Delivery Time | 1-2 weeks after payment received |

Bring your architectural vision to life with our Ivory Travertine Slab, a luxurious and versatile natural stone that delivers both elegance and character. Known for its distinctive colors, irregular textures, and natural holes, each slab showcases organic beauty, perfect for modern interiors and timeless designs.

🪨 Product Features & Advantages

- Fascinating Colors & Textures: Every ivory travertine slab is unique, with naturally formed textures and holes that reflect geological history.

- Custom Sizing for Versatile Applications: Standard slab size is 2450 x 1250mm, with square materials available to match mold dimensions for efficient cutting and installation.

- Cost-Effective Project Planning: Thanks to uniform sizing, layout is simplified, and material yield can be visualized early—helping you save time and reduce costs during installation.

- Perfect for Wall Cladding, Countertops, Flooring, and More.

🧪 Understanding Travertine Surface Challenges & Solutions

Ivory travertine is a delicate material that must be properly treated to retain its commercial and decorative value:

⚠️ Common Issues:

- Excessive holes and low compressive strength may lead to breakage.

- Blackening of the surface occurs when dust enters unfilled pores.

- Poor polishing and glue application result in surface dullness and color mismatches.

✅ Solutions:

- Color-Matched Glue Application: To maintain a natural look, glue must be tinted to match the original stone.

- Deep Hole Filling: Glue should be embedded deep into each hole to avoid wear-through during use.

- Complete Surface Polishing: Ensure the surface is polished to its full potential before and after installation for maximum brightness.

- Preventative Maintenance: Regular cleaning and sealing will preserve the integrity and color of the slab.

📦 Ordering & Logistics Information

- Sample Preparation Time: Usually 1–3 days

- MOQ: 50 square meters

- Delivery Time: 1–2 weeks per 1x20' container after deposit

- Shipping Ports: Xiamen, Qingdao, Tianjin, Wuhan, Shenzhen

- Payment Terms: 30% T/T in advance, 70% during shipment or L/C at sight

- Company Location: Xiamen, Fujian Province, China

🏗️ Our Main Products Include:

- Marble, Granite, Travertine

- Countertops & Vanity Tops

- Quartz, Limestone, Sandstone

- Stone Basins, Tombstones, and more

🌍 Why Choose PurchaseStones?

We serve 120+ countries with premium stone solutions, and our 6,000 sq. ft showroom allows clients to handpick their materials. With quality-focused processing and expert support, we’re your trusted source for natural stone slabs, delivered globally with care.

Share