1

/

of

9

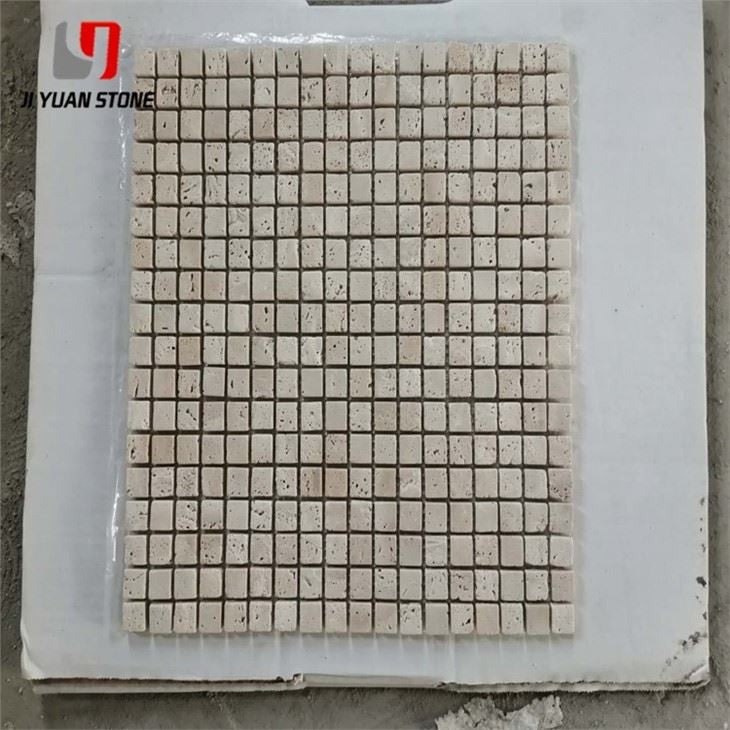

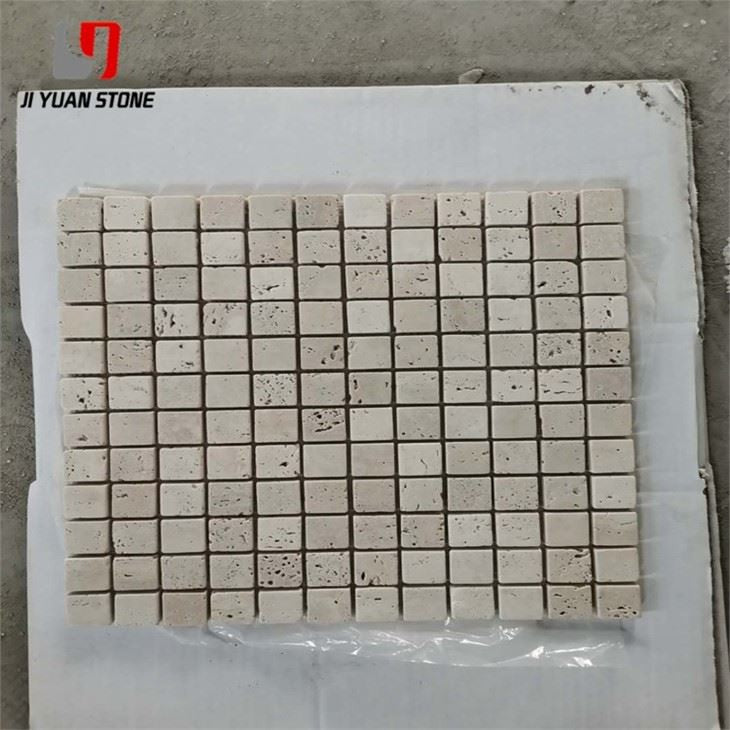

Ivory Travertine Mosaic Tile

Ivory Travertine Mosaic Tile

This Ivory Travertine Mosaic Tile adds a touch of elegance to any space. Made of high-quality ivory travertine, it provides durability and a timeless appearance. Each tile is unique, making it a perfect choice for creating a one-of-a-kind look. Perfect for backsplashes, bathrooms, and more.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Warranty | 3 years |

| After-sale Service | Online technical support |

| Size | Customized Size |

| Style | Modern |

| Occasion | Wall or Floor |

| Project Solution Capability | Total solution for projects |

| Application | Bathroom |

| Design Style | Modern |

| Place of Origin | China |

| Model Number | Brass Marble Waterjet Mosaic |

| Shape | Irregular |

1. Choice of Grout

The selection of grout should be based on design requirements and the width of the gaps between the ivory travertine mosaic tile particles.

- For high engineering requirements with narrow gaps (Y-Jl), a solvent-based liquid glue with high transparency and non-yellowing properties is recommended.

- For uniform and larger gaps, use a combination of liquid glue and a gap filler that provides brightness after polishing. Additionally, purchase matching thinners and color pastes to customize the glue color.

- For lower engineering requirements with standardized gaps, cement-containing adhesives can be used.

2. Floor Ivory Travertine Mosaic Tile Paving Construction

Paving Process

The paving process consists of the following steps:

- Preparation before paving

- Wiping and scraping the slurry

- Mosaic row board arrangement

- Paving and pasting requirements

(1) Preparation Before Paving

- Remove debris and floating dust from the working surface.

- Spray water to moisten the ground before applying the primer.

- Ensure the back net is perforated and penetrates the gaps between the particles.

- Apply an interface agent on the back mesh of the ivory travertine mosaic tile.

(2) Wiping and Scraping the Slurry

- Accurately estimate the required amount of base slurry.

- Evenly scrape and smooth the mixed slurry onto the base surface.

(3) Mosaic Row Board Arrangement

- Pre-arrange and verify the components according to the pattern requirements.

- Ensure proper splicing of patterns, seam sizes, and component mounting dimensions.

- Proper reservations should be made to prevent incorrect paving, which could lead to particle detachment.

(4) Paving and Pasting Requirements

- Once compacted, the primer must penetrate the mesh and bond with the lower part of the particles, ensuring a strong adhesion.

- Since polishing is required in later stages, the overall component paving should be 0.2 cm higher to accommodate the finishing process.

Share