Ivory Travertine Marble

Ivory Travertine Marble

Ivory Travertine Marble – Natural Aesthetics Meets Advanced Stone Technology

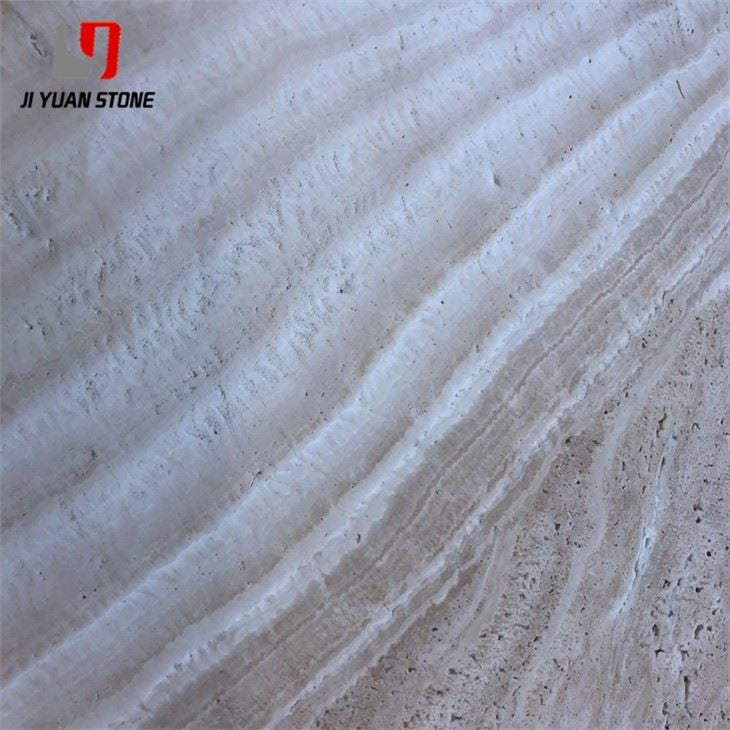

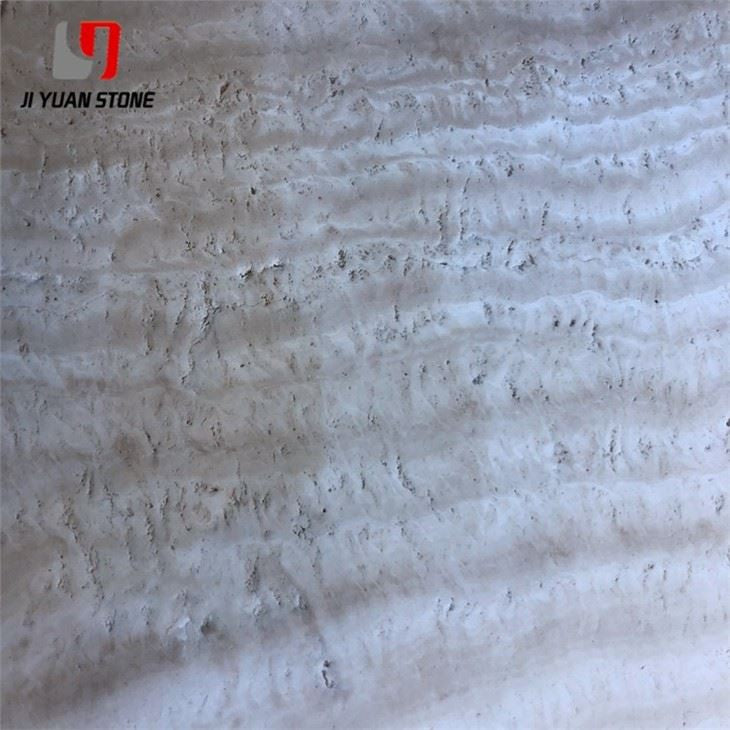

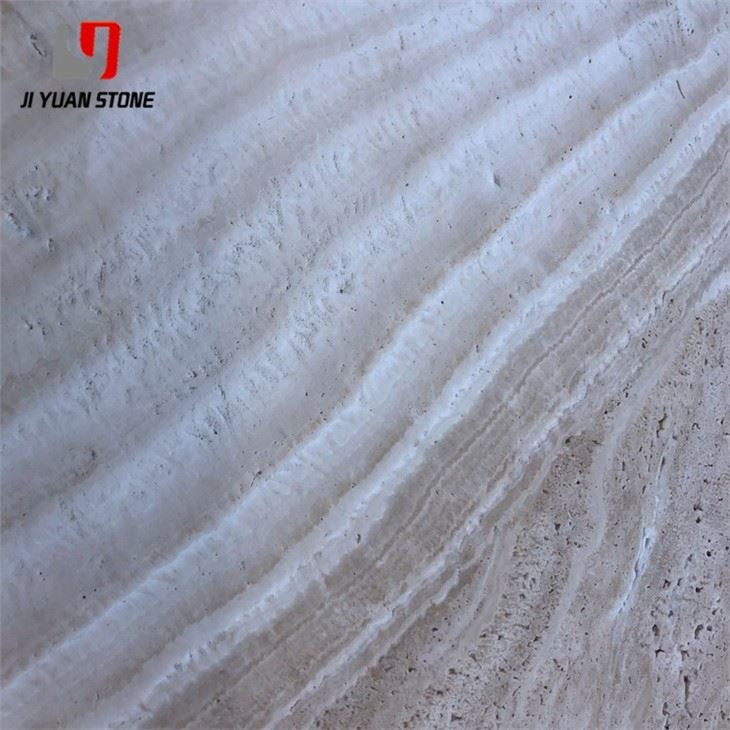

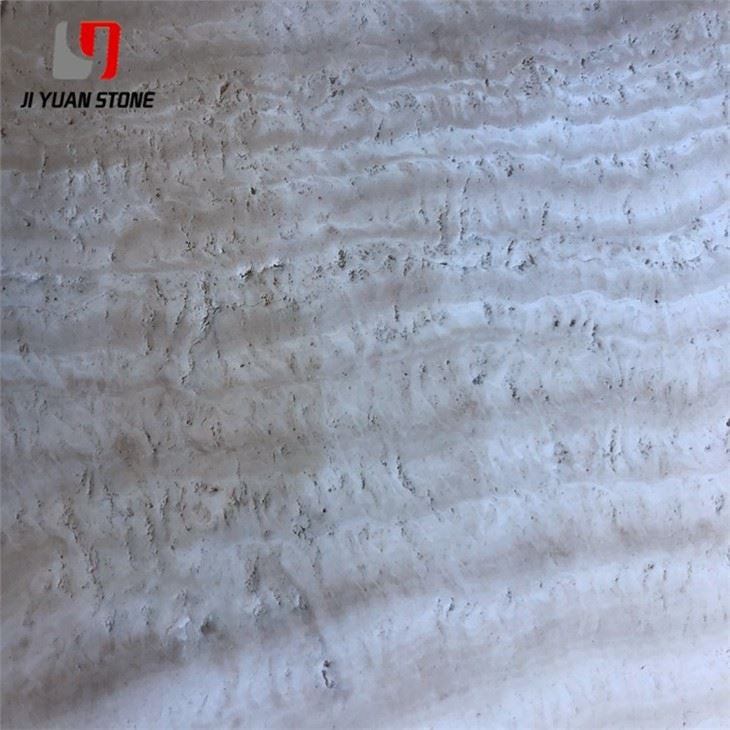

Our Ivory Travertine Marble is a stunning addition to any space. This luxurious marble boasts a timeless and classic look and is perfect for both indoor and outdoor use. With its beautiful ivory color and unique natural patterns, it adds a touch of elegance and sophistication to any room. Upgrade your home or project with the benefits of this high-quality, durable, and versatile marble.

Bring the timeless elegance of natural stone into your space with our Ivory Travertine Marble. Known for its fine, smooth texture, subtle grain penetration, and beautifully blended tones, this marble delivers a rich and authentic look that enhances both traditional and contemporary designs.

What sets our ivory travertine marble apart is the perfect harmony of natural inspiration and technical innovation. Using advanced simulation and color spraying technologies, our production captures the true essence of natural stone while ensuring consistency, durability, and artistic appeal.

🎨 Artistic Texture & Pattern Simulation

Ivory Travertine Marble is developed through meticulous linear texture techniques, turning curves into lines and cones into loops. Using dynamic mist spraying, color paste mixing, and multi-layered printing, we achieve authentic stone patterns that mimic nature—while allowing for customization and scale.

- Multi-color blending techniques simulate the unpredictable beauty of real stone.

- Fine-grain dispersion and artistic overlays provide depth and realism.

- Vacuum vibration molding and double steering cloth systems help create large-format slabs with vibrant, natural-like textures.

This approach gives the marble an edge not just in aesthetics, but also in performance and pattern uniformity—perfect for luxury floors, countertops, wall cladding, and high-end architectural spaces.

🧱 Product Highlights:

- Material: Ivory Travertine Marble

- Finish: Polished / Honed / Brushed

- Colors: Soft ivory base with natural veins and subtle tones

- Sizes Available: Standard & Custom (including large formats like 245×165cm or 325×165cm)

- Applications: Flooring, wall cladding, countertops, vanity tops, and interior design accents

📦 Frequently Asked Questions

1. What is your time of making samples?

We usually take 1–3 days to prepare the samples.

2. What is your MOQ?

The minimum order quantity is 50 square meters.

3. What is your delivery time?

Typically 1 to 2 weeks per 1x20' container after deposit confirmation.

4. Where is the shipping port?

We ship from Xiamen, Qingdao, Tianjin, Wuhan, or Shenzhen ports.

5. What is your payment term?

30% T/T in advance, 70% during shipment, or L/C at sight.

6. Where is your company located?

We are located in Xiamen, Fujian Province, China.

7. What are your main products?

Our portfolio includes Marble, Granite, Travertine, Quartz, Limestone, Sandstone, Countertops, Vanity Tops, Stone Basins, and Tombstones.

⚙️ Technology & Innovation in Manufacturing

Our Ivory Travertine Marble benefits from the integration of:

- Double stirring & dual steering cloth methods

- 6-oscillator vacuum vibration pressing system

- Multi-tone color paste mixing (2–6 color shades)

- Spray-dyeing preforms, rollers, magnetizing & cloth-patterning machines

- Large-format production with 320×160cm slabs

- Modular press balancing for even pattern distribution

These cutting-edge techniques not only simulate natural stone but improve the visual texture, surface strength, and production efficiency—making our marble both artistic and commercially viable.

🌍 Why Purchase from Us?

With over 15 years of experience in natural and engineered stone manufacturing, we offer:

- ✅ Skilled workforce and advanced machinery

- ✅ Custom sizing & finish options

- ✅ Worldwide shipping with strict quality control

- ✅ Competitive pricing and timely delivery

- ✅ Trusted export partner for premium stone

🏁 Conclusion

Ivory Travertine Marble is more than just a surface—it’s a fusion of natural beauty and human artistry. Whether you're designing a luxury interior or developing a high-end commercial project, our marble gives you a timeless look with unmatched technical finesse.

📞 Contact us today to request samples, quotes, or custom designs tailored to your vision.

Share