Ivory Natural Travertine

Ivory Natural Travertine

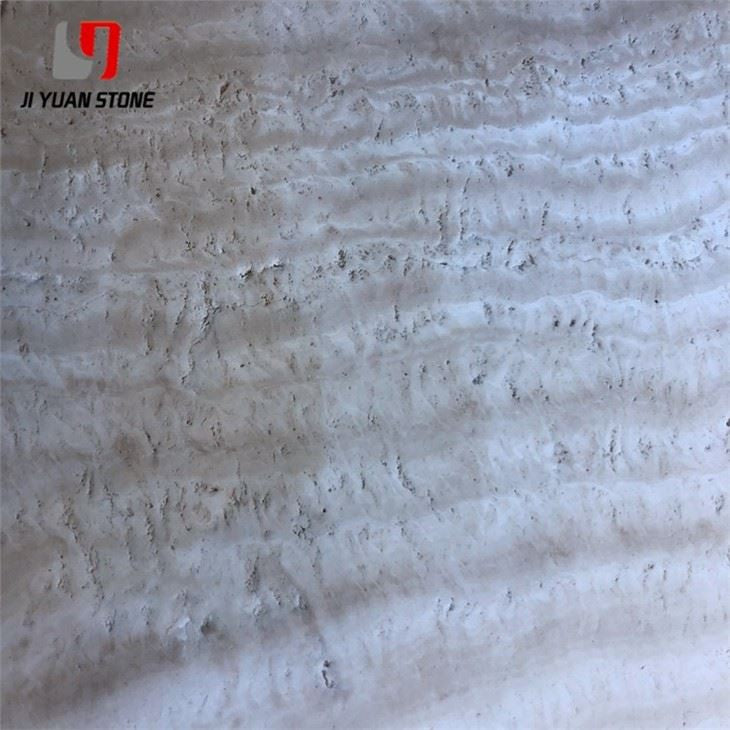

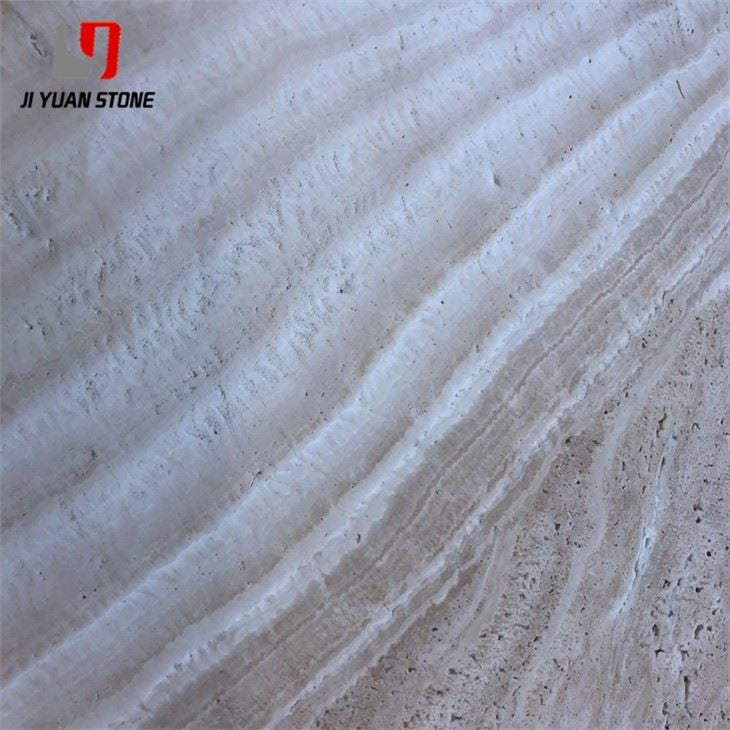

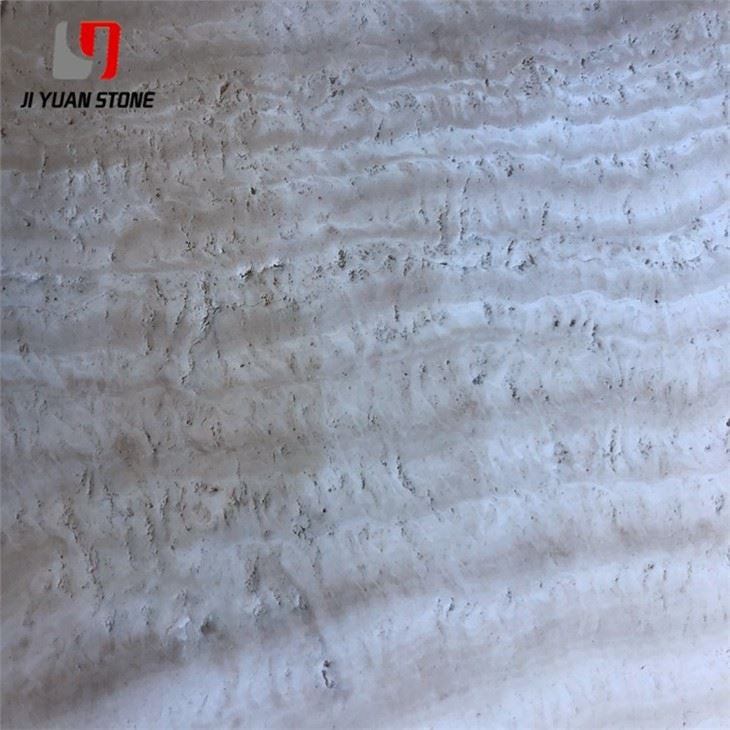

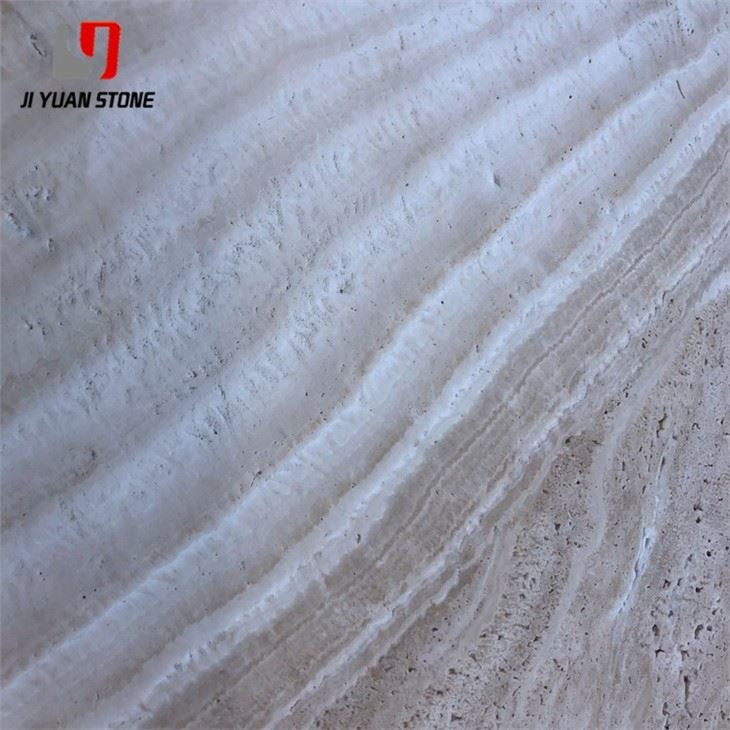

Ivory Natural Travertine – Classic Beauty with Durable Performance

Discover the timeless beauty and durability of our Ivory Natural Travertine. With its unique texture and warm neutral tones, this natural stone adds elegance to any space. Made from 100% genuine travertine, it offers a 30% higher strength rating compared to other travertine products. Perfect for both indoor and outdoor use, it will elevate your home or commercial project.

Enhance your space with the timeless charm of Ivory Natural Travertine, a premium natural stone known for its elegant creamy tones, fine texture, and outstanding durability. Ideal for both indoor and outdoor applications such as flooring, wall cladding, patios, pool decks, and facades, this stone adds warmth and sophistication to any architectural project.

Each piece of ivory natural travertine features natural variations that mimic the beauty of ancient stone, making it perfect for classic and modern spaces alike. Thanks to advanced manufacturing techniques and expert stone selection, we deliver top-tier travertine that blends nature’s authenticity with artisan craftsmanship.

✅ Technical & Service Information:

-

What is your time of making samples?

Usually, we will take 1~3 days to prepare the samples. -

What is your MOQ (Minimum Order Quantity)?

Usually 50 square meters. -

What is your delivery time?

Typically, it takes 1 to 2 weeks for a 1x20' container after receiving the deposit. -

Where is the shipping port?

We ship from Xiamen, Qingdao, Tianjin, Wuhan, or Shenzhen ports. -

What is your payment term?

30% T/T in advance, 70% during shipment. L/C at sight is also acceptable. -

Where is your company located?

We are located in Xiamen, Fujian Province, China. -

What are your main products?

Marble, Granite, Travertine, Countertops, Vanity Tops, Stone Basins, Tombstones, Quartz, Limestone, and Sandstone.

✅ Why Choose Our Ivory Natural Travertine?

We use a combination of coarse and fine calcium powders to maintain adhesion while reducing overall resin usage—improving strength without sacrificing quality. Our proprietary molding process involves intense vibration (~4200r/min) and 10–12 minutes of compaction to ensure each slab achieves optimal density and curing.

To reduce production costs and enhance fire resistance, we also explore eco-friendly alternatives like inorganic binders (special cement, water glass), and energy-saving technologies including capacitor-based motor systems.

Our focus on precision cutting using thinner saw blades (1.5–2.5 mm) minimizes material waste, further improving efficiency and sustainability. Stone hardness can also be enhanced by integrating glass cullet or partial quartz granules—an innovation to extend product life and reduce surface wear.

✅ Environmental Considerations:

We continually refine our production process to make Ivory Natural Travertine more eco-conscious. The use of optimized vacuum pumping, improved aggregate handling, and shorter operation cycles help reduce energy consumption while maintaining exceptional quality.

Experience the strength, elegance, and natural aesthetic of Ivory Natural Travertine—perfect for residential or commercial design projects. Contact us today for a custom quote, sample request, or more technical details.

Purchasestones – Your Trusted Partner in Natural Stone Solutions.

Share