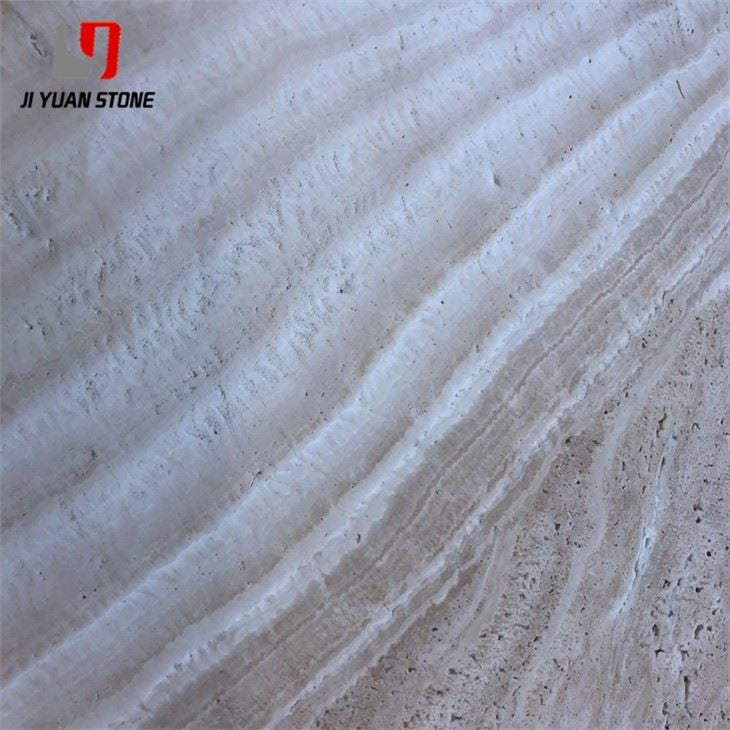

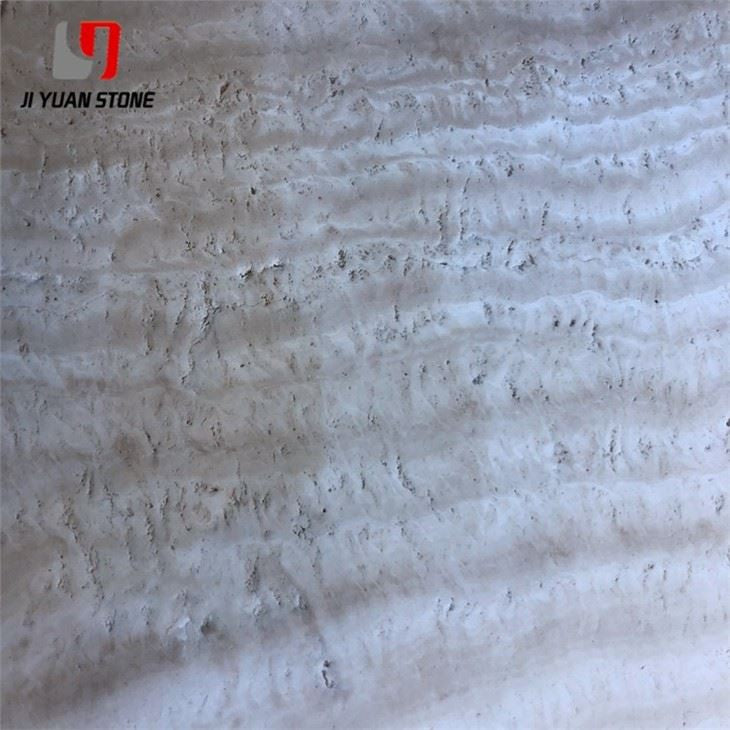

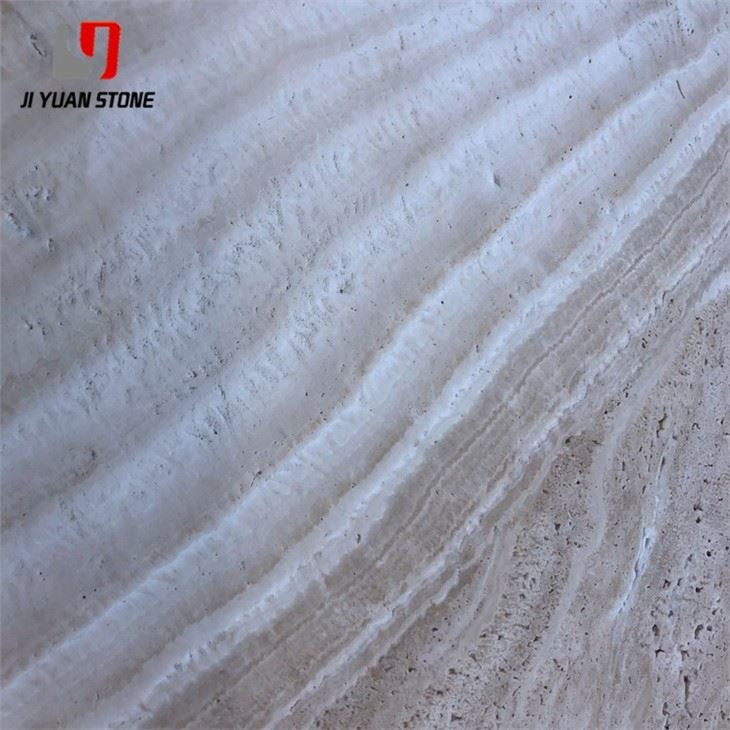

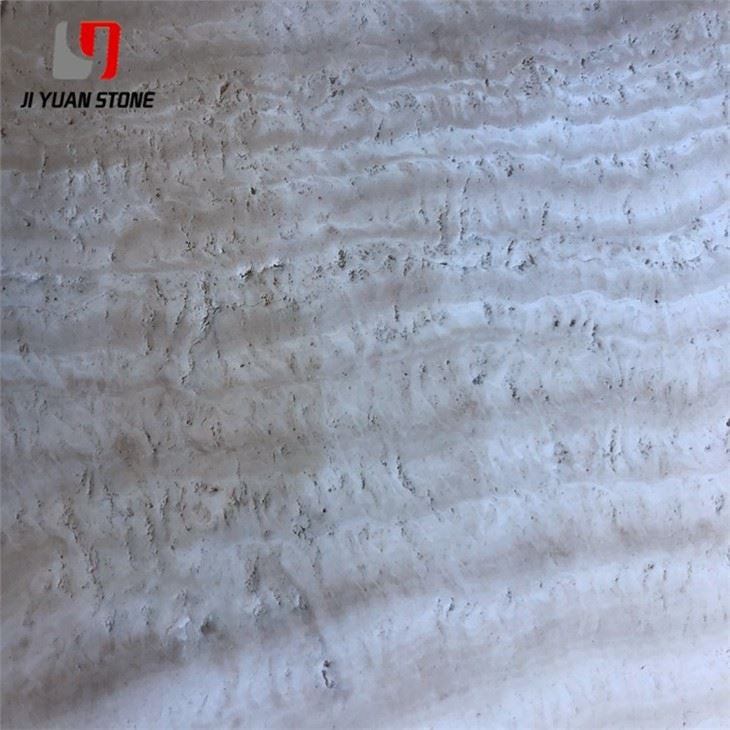

Ivory Cream Travertine

Ivory Cream Travertine

Ivory Cream Travertine – Natural Beauty Meets Functionality

As an expert in the stone industry, I can confidently assert that Ivory Cream Travertine is an excellent choice for gorgeous and durable flooring. Made from natural stone, it boasts a timeless beauty and offers a variety of benefits, including long-lasting durability and easy maintenance. Its unique coloration and patterns make each piece truly one-of-a-kind. Invest in the elegance and quality of Ivory Cream Travertine for your home or business.

Elevate your architectural designs with our Ivory Cream Travertine, a luxurious and durable natural stone offering a soft, warm tone and timeless appeal. Perfect for both interior and exterior spaces, this travertine is a preferred choice for designers, architects, and homeowners seeking elegance with performance. With its non-slip surface, micro-pores, and easy refinishing properties, it is ideal for applications such as pool surrounds, walls, flooring, and countertops.

Key Product Features:

- Soft ivory and cream shades ideal for minimalist or traditional design aesthetics

- Natural anti-slip texture for safety in wet areas like pools and bathrooms

- Mohs hardness of 3.5 – durable yet refurbishable

- Micro-crystallized finish enhances aesthetic appeal and surface longevity

- Eco-conscious production using unsaturated polyester resin

✅ Market Insights & Improvements

Despite its popularity, Ivory Cream Travertine faces challenges like high production costs and moderate wear resistance. However, continuous innovations in material science and production techniques—such as microcrystalline modification, upgraded stirring systems, and the integration of health-preserving elements—are helping enhance performance while reducing costs. Introducing modern equipment, such as MC-300 vacuum machines, has also contributed to better pricing and product stability.

Optimized manufacturing methods such as efficient heating during high-speed stirring, advanced calcium powder formulation, and improved resin utilization have significantly increased structural integrity and pattern uniformity, ensuring a refined finish and longer-lasting performance.

✅ Frequently Asked Questions:

1. What is your time of making samples?

Usually, we will take 1–3 days to make the samples.

2. What is your MOQ?

Usually 50 square meters.

3. What is your delivery time?

Usually 1 to 2 weeks for a 1x20' container after we receive the deposit.

4. Where is the shipping port?

We ship from Xiamen, Qingdao, Tianjin, Wuhan, or Shenzhen ports.

5. What is your payment term?

30% T/T in advance, 70% during shipment. Or L/C at sight.

6. Where is the location of your company?

Our factory and headquarters are located in Xiamen, Fujian Province, China.

7. What are your main products?

We supply a wide range of stone products including Marble, Granite, Travertine, Quartz, Limestone, Sandstone, Countertops, Vanity Tops, Stone Basins, Tombstones, and more.

Choose Ivory Cream Travertine for your next project and benefit from high-quality craftsmanship, reliable logistics, and personalized support. For bulk orders or customized needs, contact us today for a quote and consultation.

Share