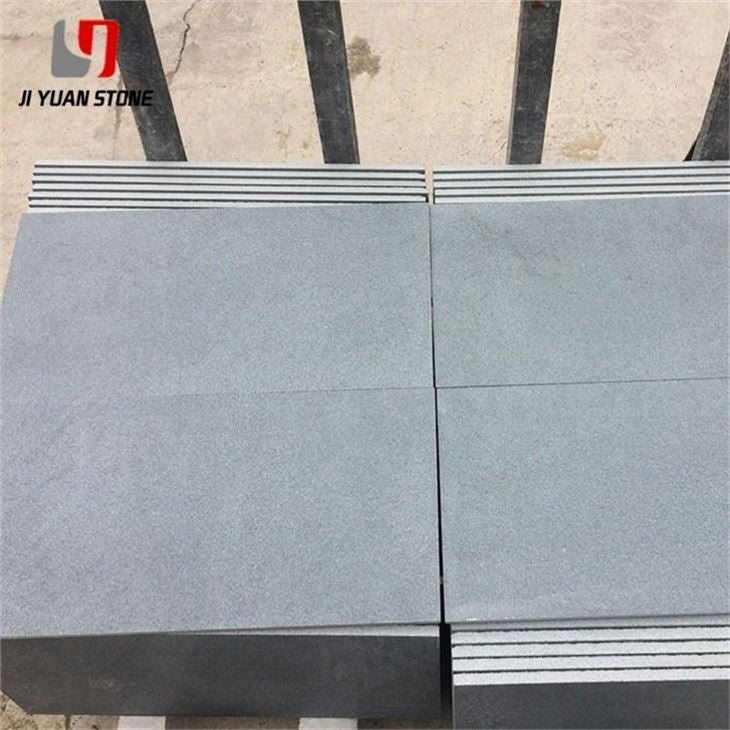

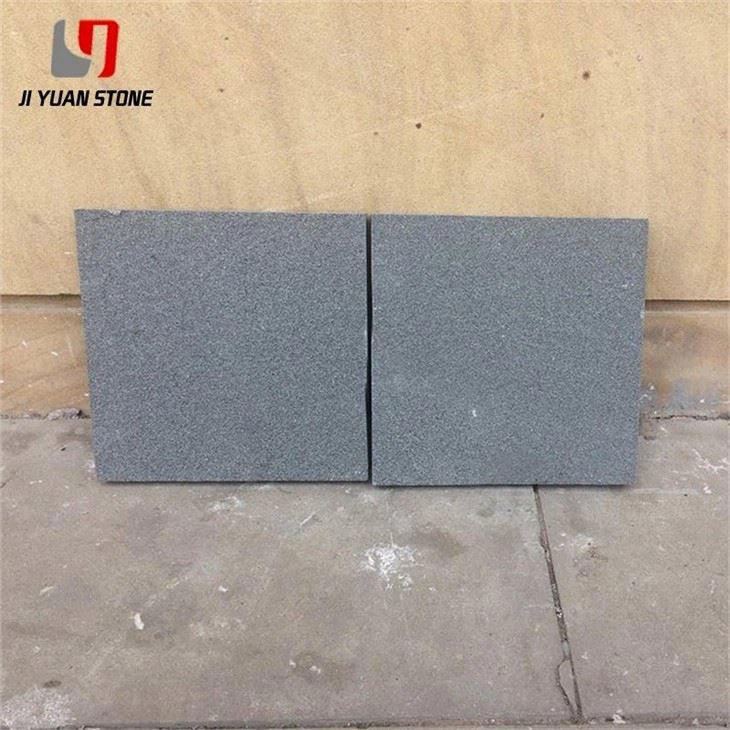

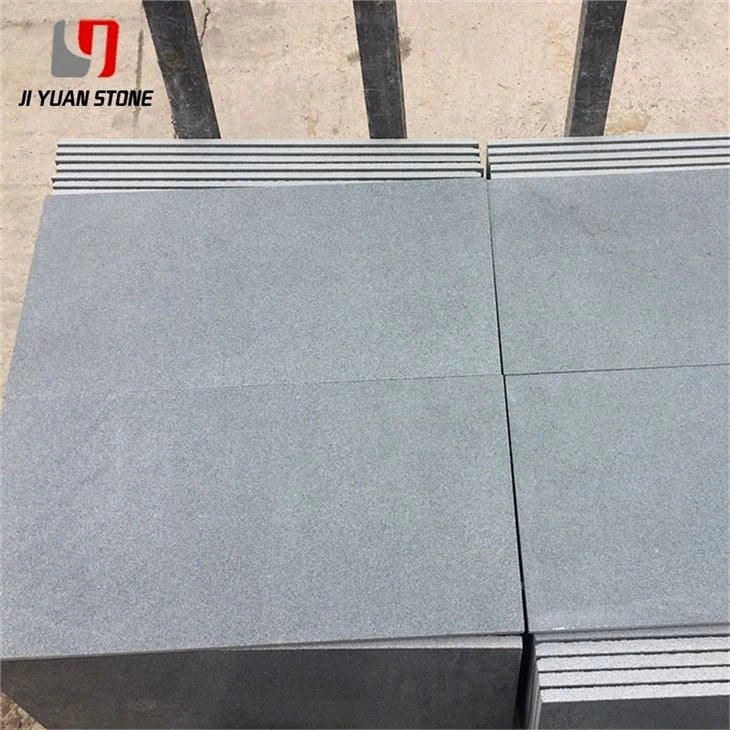

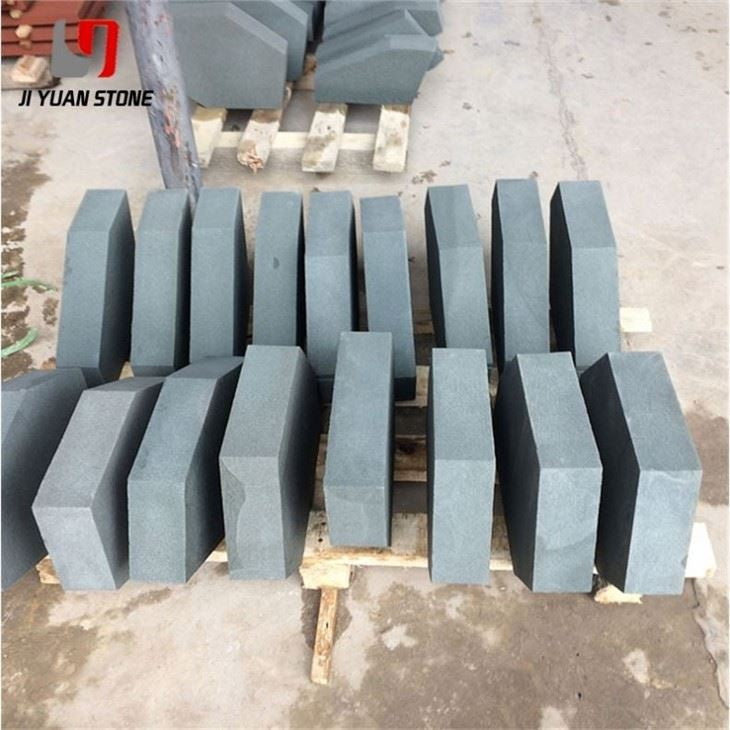

Honed Gray Sandstones Slabs

Honed Gray Sandstones Slabs

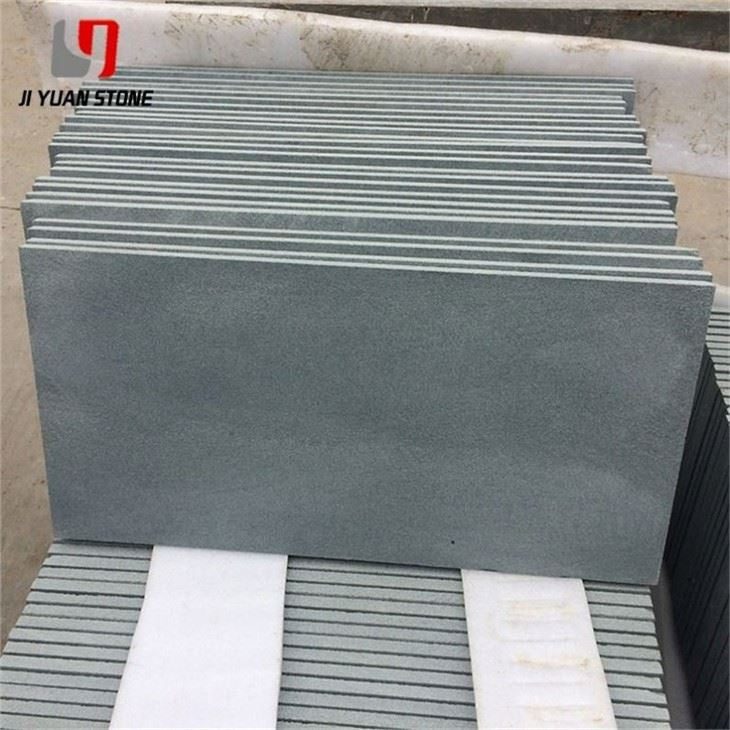

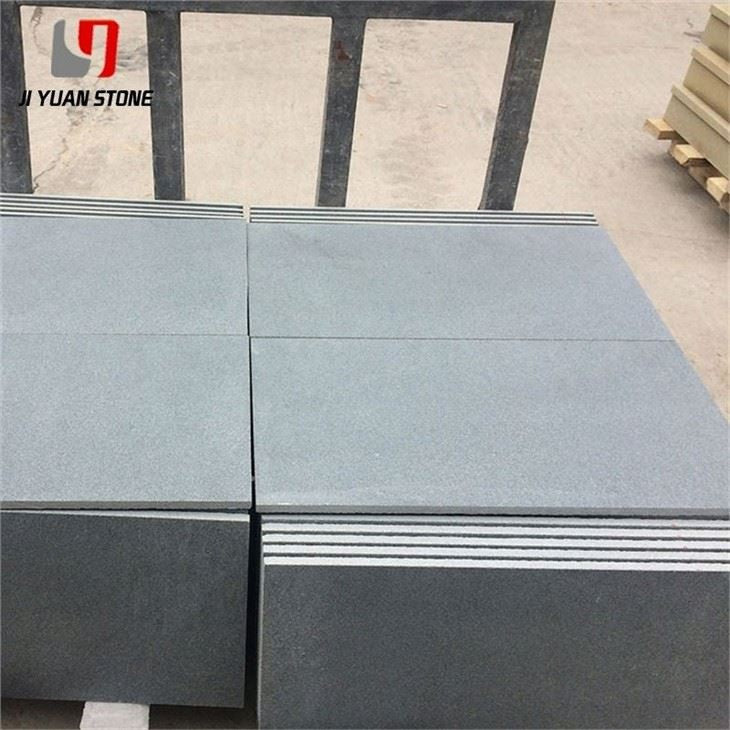

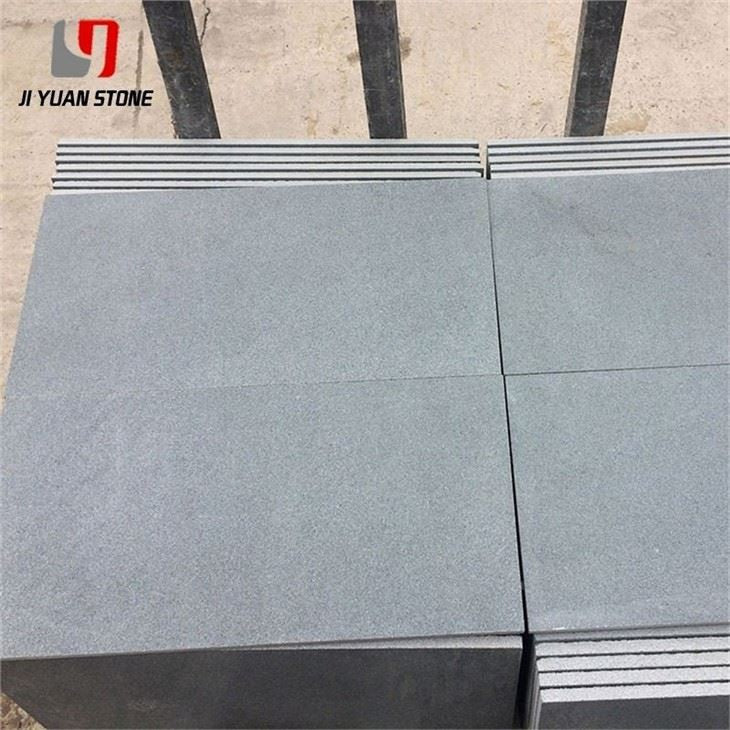

Honed Gray Sandstones Slabs are the perfect option for adding a touch of elegance and sophistication to any space. These slabs are expertly crafted with a honed finish, resulting in a smooth and sleek surface. With their durable and timeless appearance, Honed Gray Sandstones Slabs are a perfect investment for both residential and commercial projects.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

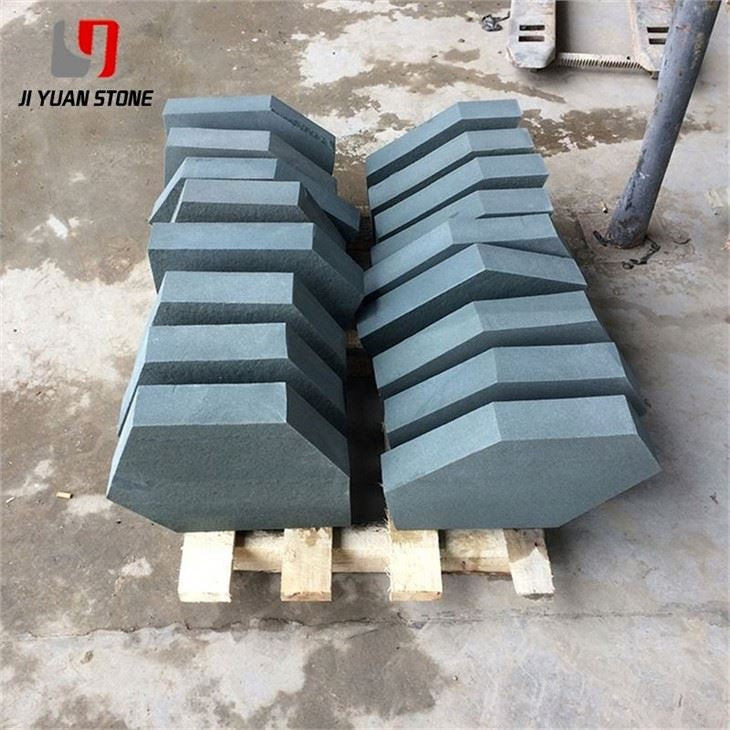

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

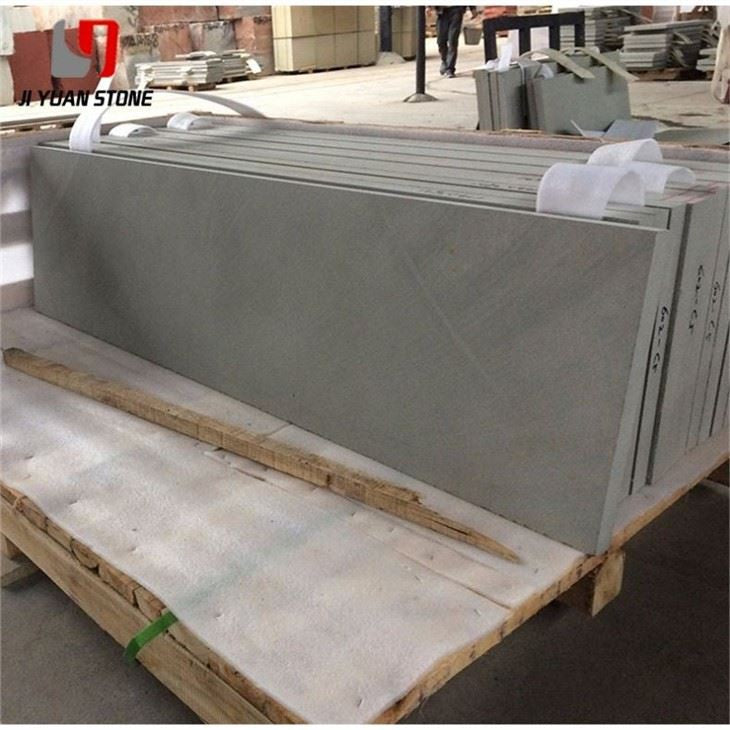

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Factors Contributing to the Yellowing of Honed Gray Sandstone Slabs

Honed gray sandstone slabs contain microcracks and voids that fall within the range of capillary pores. These pores naturally absorb various liquids, fine dust, pollutants, and both water-soluble and oil-soluble organic pigments. The higher the porosity and water absorption rate, the more susceptible the stone is to pollution and deterioration.

Main Causes of Stone Yellowing:

1. Insufficient Stone Protection

- Inadequate protection allows iron ions within the stone to react with water, forming iron oxide, which leads to yellowing.

- This issue is particularly common in white stone varieties such as Yashi White, Jazz White, and Large White.

2. Contamination During Processing

- Machinery, equipment, and blade rust spots can contaminate the back of the stone, leading to discoloration.

3. Poor Protection of the Finished Product

- Exposure to iron elements without proper protective measures can cause rust formation, which damages the stone and results in yellowing.

4. Irregular or Improper Maintenance

- Using inferior acid-based cleaning agents can cause a chemical reaction with steel wool, allowing harmful substances to penetrate the stone's pores and cause yellowing.

5. Use of Inappropriate Waxes or Substances

- Applying waxes containing pigments, acids, or alkalis during the grinding process can cause discoloration and yellowing over time.

Share