1

/

of

9

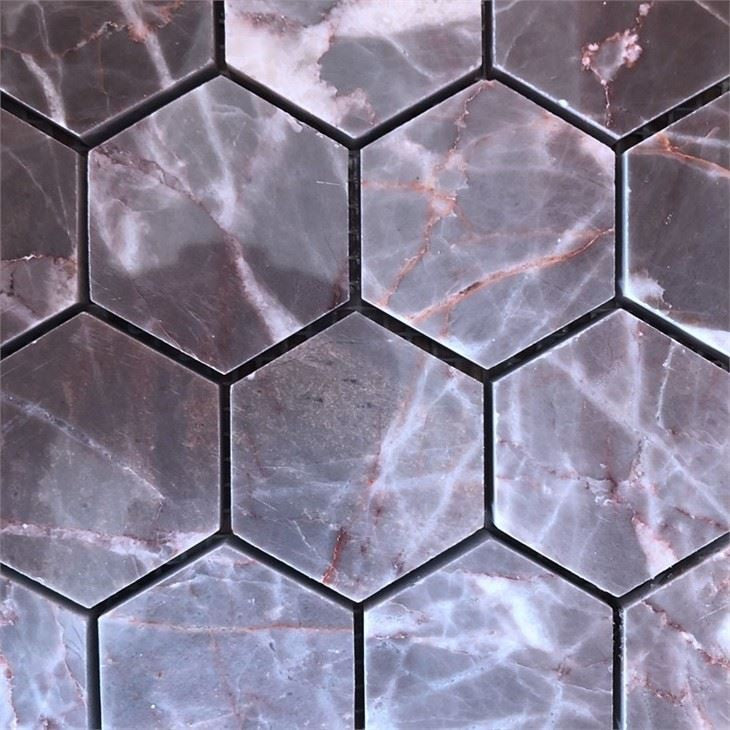

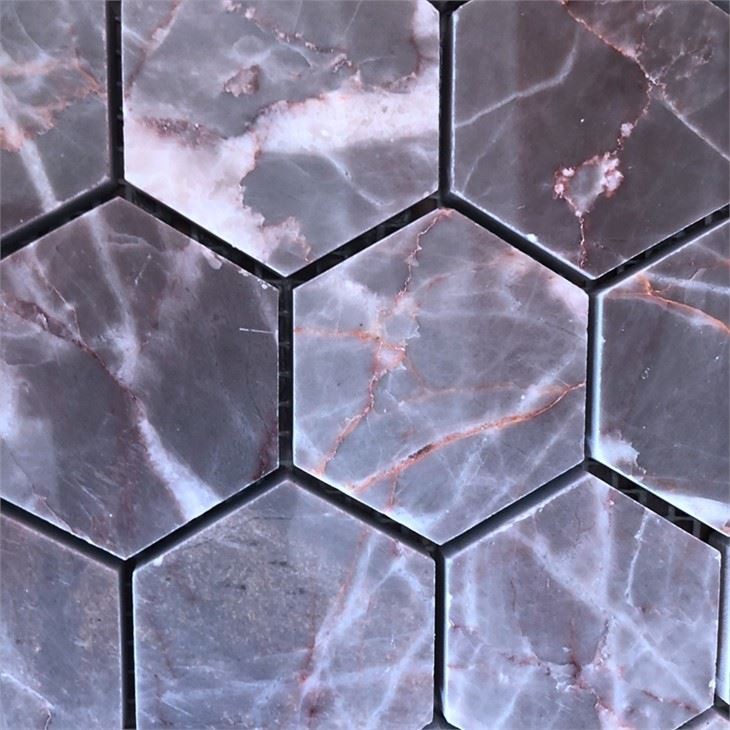

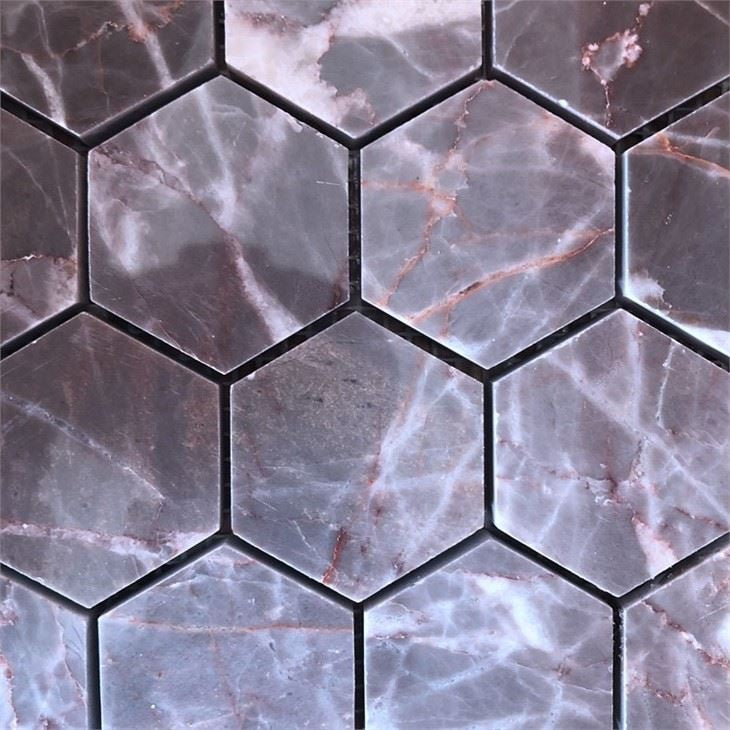

Grey Marble Mosaic

Grey Marble Mosaic

This Grey Marble Mosaic combines the natural beauty of marble with a modern touch. Made with high-quality grey marble, it adds elegance to any space. Its durable and versatile design makes it suitable for both indoor and outdoor use. Transform your home or office with this luxurious and timeless mosaic.

| Feature | Details |

|---|---|

| Material | Natural Marble Stone,Travertine,Limestone |

| Colour | As pictures show or customized |

| Shape | Square, Basketweave, Mini brick, Modern brick, Herringbone, Subway, Hexagon, Octagon, Mixed, Grand fan, Penny round, Hand clipped, Tesserae, Random strip, River rocks, 3D cambered, Pinwheel, Rhomboid, Bubble round, Circle bubble, Stacked, etc... |

| MOQ | Unrestricted |

| Product Material | Marble |

| Surface Choice | Polished, Honed, Flamed, Antique, Stripped, Bush-hammered, Picked, Sawn, Sandblasted, Tumbled, Brushed, Rough, Lined, Acid-wash, etc. |

| Products Choice | Dry-hangs, Cut-to-Sizes, Panels, Slabs, Tops, Sanitary, Blocks, Stair Steps, Paving, Curbs, Columns, Pillars, Swimming Pool Borders, Tombstone, Sculptures, Fountains, Lanterns, Pots, Tables & Chairs, Meshed Paving, Mosaics etc. |

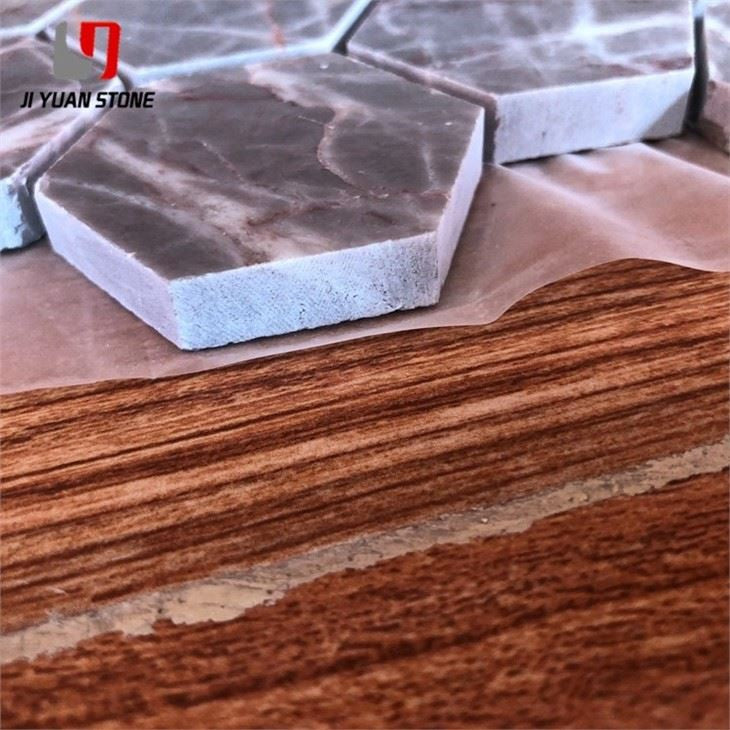

| Mosaics | 305x305Size(mm) |

| Thickness(mm) | 10-20 |

| Package | (Poly) Wooden Crate, Pallet, Rain Cloth, Carton & Foam are Our Usual Packing Material, But Different Product Different Pack, Different Pack Different Cost. |

Processing Approach for Grey Marble Mosaic Walls

1. Grinding is Not Recommended

We do not recommend grinding the grey marble mosaic wall surface due to the following reason:

- Grinding does not improve the appearance – The original board installation results in a superior visual effect compared to the time-consuming and labor-intensive grinding process.

For this reason, we advise against grinding the wall surface.

2. Alternative Approaches for Wall Installation

Through long-term experience, we have summarized three effective techniques for handling the flatness of dry-hanging grey marble mosaic walls.

A. Wooden Wedge Adjustment

- If there is an obvious height difference between two adjacent plates, use wooden wedges to adjust the alignment.

-

Method:

- Cut wooden wedges to an appropriate size.

- Insert them under the recessed plate along the edge to adjust the height difference.

- Best for: Plates over 600mm in height.

- Not recommended for: Plates below 600mm, as the hammering process can cause deformation or breakage.

B. Groove & Gap Treatment

- Process the plate joints into various grooves to visually minimize height differences.

-

Common groove types:

- V-shaped grooves

- T-shaped grooves

- Other decorative groove styles

- Left seams

-

Advantages:

- Helps blend joints visually to eliminate noticeable height differences.

- Enhances the aesthetic appeal through unique finishing methods.

Share