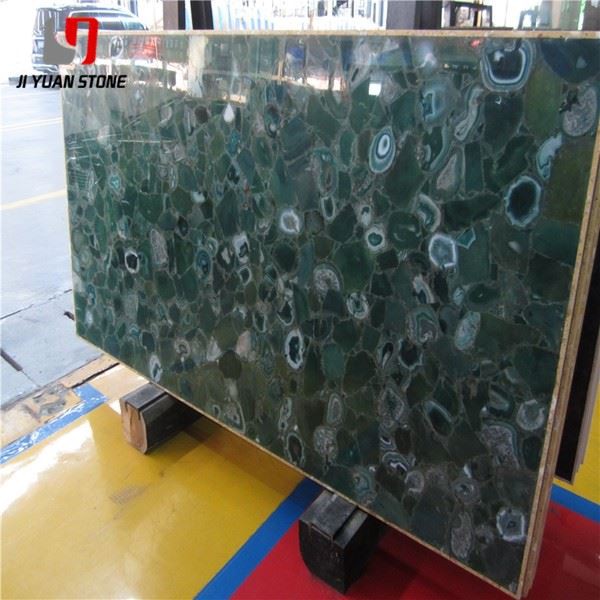

Green Gemstone Slabs

Green Gemstone Slabs

Green Gemstone Slabs – Eco-Friendly, Sustainable, and Luxurious Stone

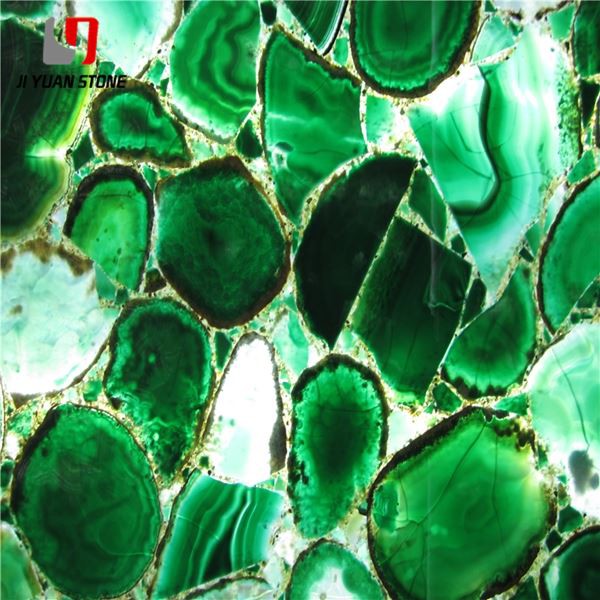

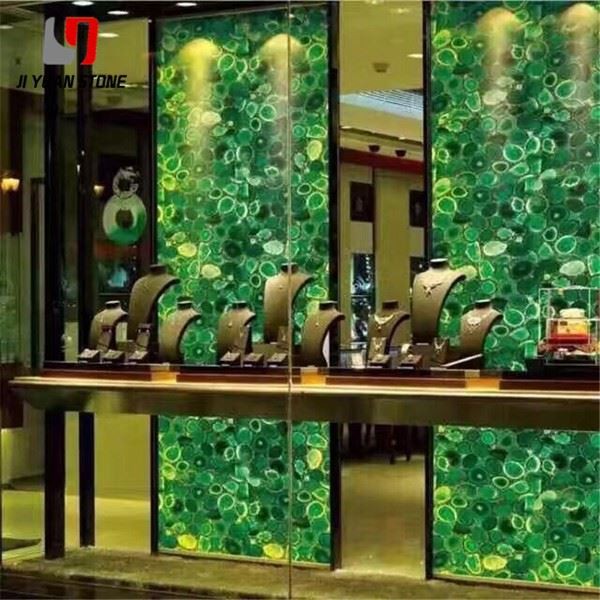

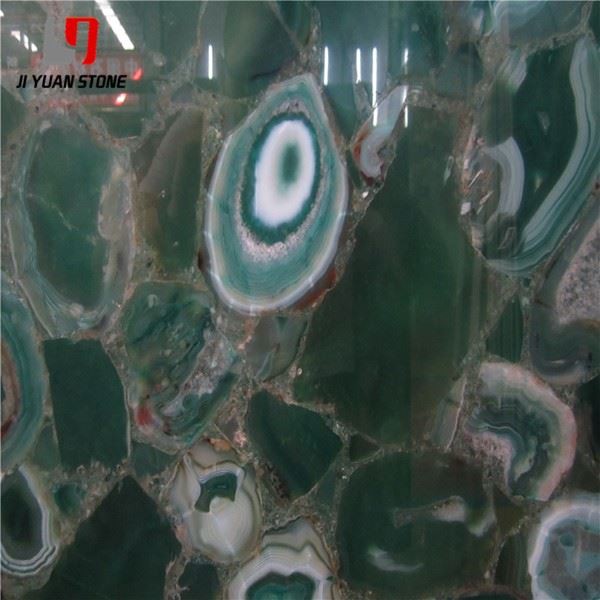

Crafted from high-quality green gemstones, these slabs add a touch of elegance to any space. With their natural beauty and durability, they are perfect for countertops, tabletops, and decor pieces. Elevate your home or office with the stunning colors and texture of these gemstone slabs.

| Feature | Details |

|---|---|

| Product Name | Green Gemstone Slabs |

| Material | 100% Agate Gemstone |

| Surface Finished | Honed,Polished |

| Finished Products | Floor Tiles, Wall Cladding, Countertops, Windowsills, Special-Shaped Tiles, Small Slabs, Swimming Pool, Steps, Wall Panel, Flooring, Veneers, Slabs, Coping Tiles etc. |

| Color | Yellow,Black,White,Red,Purple Wood,Green,Grey,Pink,Rainbow,Pink,Tiger Eye etc |

| Size | Any sizes customized are welcome |

| Edge Available | Polished, Bush Hammer, Flat, Flamed, Eased, Beveled, Bullnose, Ogee, Cove, Dupont, laminated, non-laminated and etc. |

| Thickness | 10/15/18/20/25/30mm etc |

| Usage | Indoor/Outdoor Decoration, For floor or wall, Counter tops, Vanity tops |

| Packing | Seaworthy Wooden Crate |

Green Gemstone Slabs are not only admired for their brilliant green tones and natural patterns but also for their role in promoting sustainability in the stone industry. Perfect for luxury flooring, countertops, wall cladding, and decorative interiors, these slabs combine artistic beauty, durability, and eco-conscious production practices.

The modern stone industry has embraced green technologies and sustainable methods, ensuring that the production of Green Gemstone Slabs aligns with environmental protection standards.

1. Efficient Use of Water in Stone Processing

Water is an essential resource in stone cutting and polishing, and the industry prioritizes recycling and reusing water to minimize waste.

Field inspections by the China Stone Industry Association across key stone-producing regions such as Fujian, Shandong, Guangdong, Guangxi, Hubei, and Xinjiang confirm that:

- Most stone factories use recycled water in processing.

- No harmful chemicals are involved—only clean water is required to cool mining and processing tools.

- Even when wastewater is discharged, it fully meets environmental safety standards.

This ensures that Green Gemstone Slabs are produced through water-efficient, eco-safe processes.

2. Waste Recycling and Reuse

The stone industry has developed advanced waste management and recycling systems, turning by-products into useful materials:

- Stone powder & gravel → repurposed as concrete aggregates.

- Waste materials → used in high-strength bricks and artificial stone fillers.

- Lightweight stone powder → added to wall materials for construction.

- Stone residues → shaped into paving stones and curbs.

This circular approach minimizes waste, reduces environmental impact, and maximizes resource efficiency.

3. Adoption of Eco-Friendly Mining Techniques

Modern quarrying methods have abandoned traditional blasting techniques that damaged the environment. Instead, eco-conscious methods are used:

Cold mining technology is now standard, which:

- Improves mining efficiency.

- Increases resource utilization rates.

- Minimizes environmental harm.

This makes the sourcing of Green Gemstone Slabs more sustainable and resource-friendly.

4. Zero Pollution Stone Processing

The processing of Green Gemstone Slabs is designed to be clean, safe, and environmentally responsible:

- Processing is a purely physical procedure with no chemical pollution.

- Mechanical operations significantly reduce energy consumption.

- Wet cutting methods are used to control and minimize dust levels.

- Residual waste is non-toxic and non-polluting, ensuring no secondary environmental damage.

This makes Green Gemstone Slabs one of the most eco-friendly building materials available today.

🌟 Conclusion

Green Gemstone Slabs represent the perfect balance of luxury and sustainability. With their natural green beauty, durability, and versatile applications, they enhance any architectural or interior design project. At the same time, their eco-friendly production process—recycling water, reusing waste, adopting clean mining techniques, and ensuring zero pollution—makes them a responsible and future-ready choice.

Choosing Green Gemstone Slabs means investing in a material that is beautiful, durable, and environmentally sustainable—ideal for flooring, countertops, wall designs, and premium décor projects.

Share