Flexible Stone Wall Tiles

Flexible Stone Wall Tiles

Flexible Stone Wall Tiles – Durable, Elegant, and Perfect for Curtain Wall Cladding

Discover the perfect combination of style and versatility with our Flexible Stone Wall Tiles. Made with high-quality materials, these tiles offer durability and easy installation. Elevate any space with the natural beauty of stone and the convenience of flexibility. Upgrade your walls with these stunning tiles today!

| Feature | Details |

|---|---|

| Product | Flexible stone wall tiles |

| Surface | Polished |

| Finished Products | Floor tiles, Wall cladding etc |

| Colour | Many colors available |

| Origin | China |

| Size | 2400↑↓* 1200↑↓* 18/20/30mm |

| Finish available | Polished, honed |

| MOQ | Any trial order is welcomed |

| Sample | Free samples are available |

| Density | 2.9kg/m3 |

| Thickness tolerance | +/- 1mm |

| Quality control | 100 percent inspection and a detailed inspection report for approval before loadingPackage |

| Package | Strong seaworthy fumigated wooden bundle. 13 to 15 pieces of slabs per bundle |

| Port | Xiamen, China |

| Value-added service | Free Auto-CAD drawings for dry lay and book match pattern |

| Lead time | 7 to 10 days after the deposit is received ( Based on one container quantity) |

| Payment terms | T/T, L/C, PayPal, Western Union, Trade Assurance |

Flexible Stone Wall Tiles offer a modern solution for architectural cladding, combining high durability with natural stone aesthetics. Known for their excellent frost resistance and compressive strength, these tiles are widely used in curtain wall systems across commercial and residential projects. Whether you're upgrading your façade or starting a new construction, flexible stone tiles provide the strength, flexibility, and visual appeal needed for long-lasting exteriors.

🏗️ Why Choose Flexible Stone Wall Tiles?

- High Frost Resistance: Withstands harsh weather conditions, making it ideal for exterior applications.

- Superior Compressive Strength: Delivers lasting structural integrity in building facades.

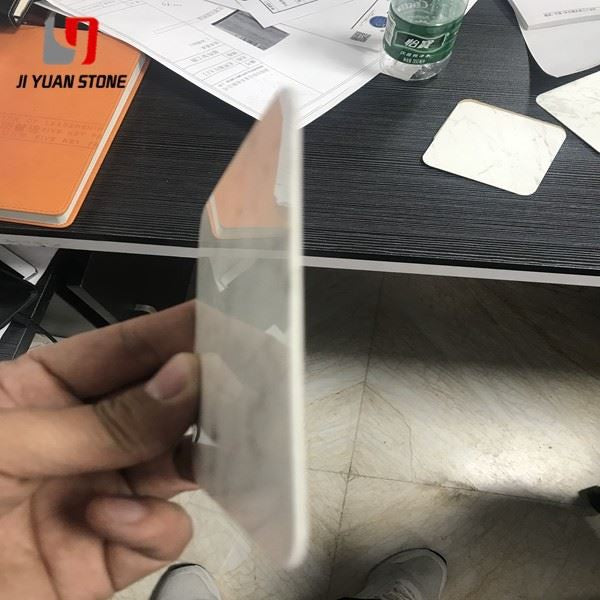

- Lightweight and Flexible: Easier to install on curved or complex surfaces compared to traditional stone panels.

- Luxurious Appearance: The surface is bright and crystal-clear, creating a noble and elegant visual impact.

🧱 Curtain Wall Applications & Construction Process

Flexible stone wall tiles are a preferred choice in stone curtain wall systems, admired for their seamless integration and refined finish. Below is an overview of the standard construction process and acceptance guidelines:

📐 1. Measurement and Layout (Paying Off)

-

Datum Point Setup:

Using a total station, workers establish the external control line on the ground floor and transfer it vertically using a laser instrument to align with the top floor. -

Control Line Establishment:

Vertical steel lines are fixed every two floors, and horizontal lines every 4 meters to maintain precision during installation. -

Dimensional Checks:

All hole sizes are measured relative to axis elevation to ensure accurate fitment.

🔩 2. Adapter Installation

- Adapters are positioned based on design specifications and secured with stainless steel bolts onto embedded parts.

- Adjustments are made to ensure no deviation in height, depth, or side alignment beyond tolerance levels.

🏗️ 3. Steel Frame Installation

a . Steel Pipe Columns:

- Verify bolt hole placement and connect steel pipes with adapters.

- Hoist into position and align per layout lines.

- Secure with initial tightening followed by final alignment.

b . Channel Beam Installation:

- Beams are mounted using corner brackets and bolts, forming the foundation of the curtain wall support system.

✨ Aesthetic and Structural Advantages

Flexible stone wall tiles don’t just look stunning—they are engineered for performance:

- Elegant Finish: Crystal-clear texture gives your building a premium appearance.

- Environmentally Resilient: Perfect for high-rise buildings, commercial complexes, and modern residences.

- Easy Maintenance: Natural stone finish is easy to clean and maintain, retaining its beauty for years.

🧾 Product Specifications

- Material: Flexible natural stone laminate

- Application: Exterior cladding, curtain walls, façades

- Finish Options: Matte, polished, crystal-clear

- Installation: Compatible with steel frame and adapter systems

- Weather Resistance: High frost and temperature resilience

Upgrade your exterior architecture with Flexible Stone Wall Tiles—where durability meets design. Explore refined style and enduring performance for your next project.

Share