Flexible Marble

Flexible Marble

Flexible Marble – Modern Elegance for Every Surface

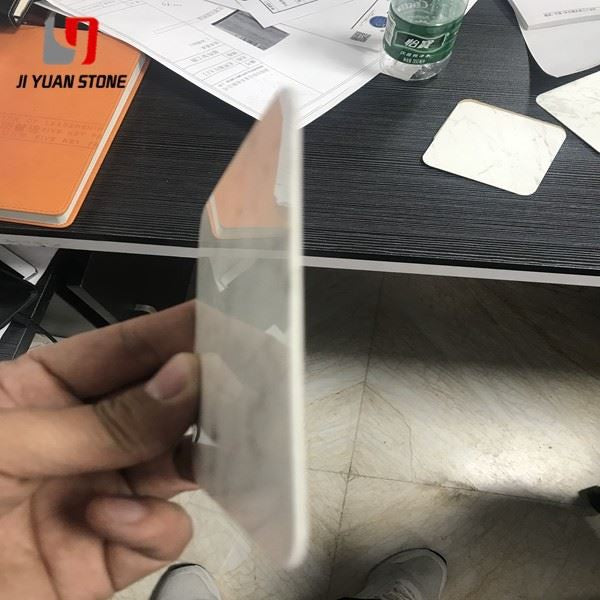

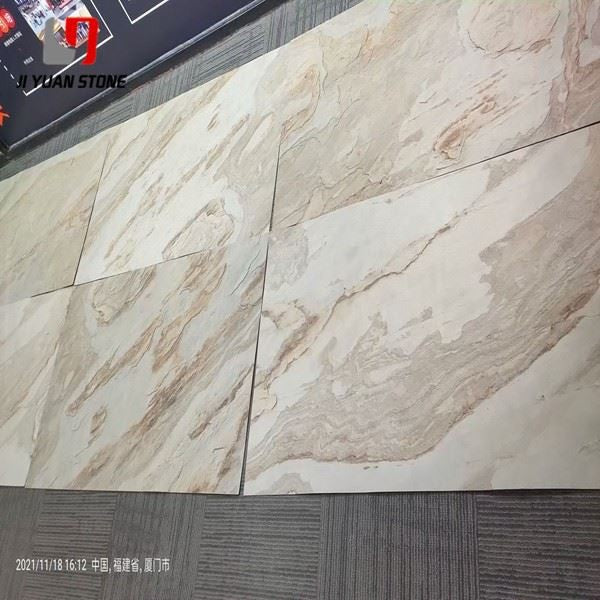

Flexible Marble combines the timeless elegance of natural stone with innovative engineering for unprecedented versatility. This revolutionary material maintains the authentic visual appeal of genuine marble while offering superior flexibility, making it ideal for curved surfaces and complex architectural applications. Its lightweight composition facilitates easier installation while reducing structural load requirements compared to traditional marble slabs.

| Feature | Details |

|---|---|

| Product | Flexible marble |

| Surface | Polished |

| Finished Products | Floor tiles, Wall cladding etc |

| Colour | Many colors available |

| Stone Type | Average weight: 1-2mm thickness, average weight 2kgs per sqm Stone Surface Finish: Polished, Honed and Brushed. |

| Backing | Fibreglass |

| Thickness | 1-5mm, or Customized |

| Biggest Size |

|

| Average Weight | 1-2mm thickness, average weight 2kgs per sqm |

| Cutting Machine | Tool scissors, Portable marble cutting machine, Portable angle grinder, Infrared bridge cutting machine, Table saw |

| Installation Instructions: |

1. Measure size-paste textured paper-draw lines 2. Stone cutting and edge grinding 3. If there is a need to dig holes, use a hand-held electric drill to punch around first and then use a hand-held angle grinder 4. Stone gluing (even grid-like gluing, at least 1 cm away from the edge of the stone to prevent glue overflowed) 5. DIY collage according to your own preference |

| Applications |

|

| Applicable Substrate | Wood, metal, acrylic, glass, ceramic, cement board, Gypsum board and another flat surfaces. |

| Can it be bending? | Yes |

| Can it be rolled up? | Thickness 1-2mm Can be rolled up. |

| Can it be a drill? | Yes |

| Can it be transparent? | Yes |

Flexible Marble is the new favorite in interior design—blending luxury, safety, and versatility in one innovative material. Whether enhancing a living room feature wall or protecting wet zones like shower rooms, this lightweight stone veneer offers a flexible solution without compromising on visual appeal or durability.

🏡 Where Flexibility Meets Function

Flexible marble is a popular choice for today's homes, offering the look of traditional stone in a format that’s easier to install and work with. It’s commonly used in areas like:

- TV background walls

- Window sills

- Bathroom shower rooms

- Staircases

- Roman columns

- Custom decorative features

Its bendable structure and lightweight form allow it to be applied in tight corners and uneven surfaces—making it ideal for both flat and curved installations.

🚿 Safe and Stylish for Wet Areas

Bathrooms require materials that are both decorative and functional. In shower rooms, flexible marble paired with stone trough boards offers multiple benefits:

- Directs water flow

- Prevents slipping with anti-skid design

- Enhances aesthetics of otherwise plain areas

This makes it a safe and elegant choice for high-moisture environments where beauty and practicality must go hand-in-hand.

🔧 Flexible Marble Grooving Process: Engineered for Precision

For features like stair grooves, Roman columns, or decorative slots, flexible marble is processed with exacting detail:

1 . Bridge Cutting – Select a board that meets processing quality requirements. Boards with uneven or low strength can crack post-groove.

2 . Material Thickness Control – The board should not vary more than ±1mm to prevent structural issues. Groove thickness should also not exceed 1mm to avoid quality complaints.

3 . Groove Size and Splicing – For boards under 500mm that require splicing, precision is key. Combine cutting and slitting during bridge cutting to avoid splicing misalignments due to:

- Equipment limitations (e.g., copier or slot-pulling tools)

- Water mill deformation

- Hook misalignment from manual handling

The goal: zero error in groove alignment for a flawless finish.

💡 Why Choose Flexible Marble?

- ✅ Lightweight & easy to handle

- ✅ Perfect for corners, curves, and detailed grooves

- ✅ Water-resistant & ideal for bathrooms and wet zones

- ✅ Anti-slip functionality for safe use on floors or showers

- ✅ Elegant finish that elevates any space

🛒 Applications

- TV Feature Walls

- Shower Room Wall Panels & Trough Boards

- Stair Pull Slots

- Roman Columns

- Kitchen & Bathroom Decorative Panels

- Residential & Commercial Spaces

Upgrade your interior with Flexible Marble—a stylish, safe, and modern alternative to traditional stone. Whether you're enhancing aesthetics or improving function in high-moisture areas, this versatile material delivers long-lasting results.

Share