Flex Marble Sheet

Flex Marble Sheet

Flex Marble Sheet – The Ultimate Lightweight Stone Solution

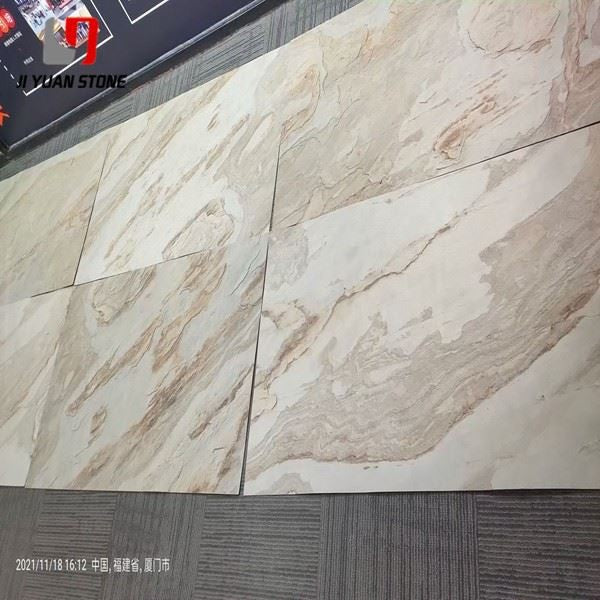

Enhance the look of your space with our Flex Marble Sheet. Made from high-quality materials, it offers the flexibility and durability to create a seamless design. With its marble-like finish, it adds a touch of elegance to any surface. Upgrade your home or office with our versatile Flex Marble Sheet.

| Feature | Details |

|---|---|

| Product | Flex marble |

| Surface | Polished |

| Finished Products | Floor tiles, Wall cladding etc |

| Colour | Many colors available |

| Stone Type | Average weight: 1-2mm thickness, average weight 2kgs per sqm Stone Surface Finish: Polished, Honed and Brushed. |

| Backing | Fibreglass |

| Thickness | 1-5mm, or Customized |

| Biggest Size |

|

| Average Weight | 1-2mm thickness, average weight 2kgs per sqm |

| Cutting Machine | Tool scissors, Portable marble cutting machine, Portable angle grinder, Infrared bridge cutting machine, Table saw |

| Installation Instructions: |

1. Measure size-paste textured paper-draw lines 2. Stone cutting and edge grinding 3. If there is a need to dig holes, use a hand-held electric drill to punch around first and then use a hand-held angle grinder 4. Stone gluing (even grid-like gluing, at least 1 cm away from the edge of the stone to prevent glue overflowed) 5. DIY collage according to your own preference |

| Applications |

|

| Applicable Substrate | Wood, metal, acrylic, glass, ceramic, cement board, Gypsum board and another flat surfaces. |

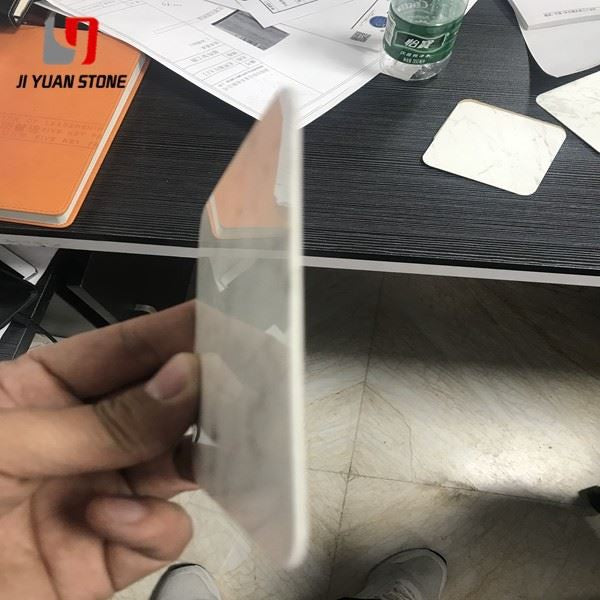

| Can it be bending? | Yes |

| Can it be rolled up? | Thickness 1-2mm Can be rolled up. |

| Can it be a drill? | Yes |

| Can it be transparent? | Yes |

Bring a sleek, contemporary look to your space with our Flex Marble Sheets, a smart alternative to traditional stone slabs. Engineered for flexibility, rapid installation, and superior aesthetics, these sheets are ideal for modern architecture, renovations, and quick stone repairs.

Whether you're designing feature walls, furniture cladding, or quick-fix stone repairs, our flex marble sheet delivers beauty and function in one ultra-thin, highly adaptable product.

🧪 Materials & Adhesive Technology Overview

Flex Marble Sheet Glue:

- The main component is unsaturated polyester resin, making it ideal for rigid bonding applications.

- When mixed with the correct proportion of curing agent, it enables fast positioning and effective bonding, commonly used for quick repairs and non-structural fixes.

Epoxy Stone Dry-Hanging Glue:

- A modified epoxy resin polymer (A+B compound) offering a flexible combination with longer working time, ideal for structural dry-hanging installations.

- Known for its permanent bonding strength, weather resistance, and anti-aging properties.

⏱ Curing Time Comparison

Flex Marble Sheet Glue:

- Ultra-fast gelation – can start to set within seconds

- Fully cured in about 5 minutes at room temperature

- Cures even at low temperatures (as low as -10°C)

Epoxy Dry-Hanging Glue:

- Pot life: ~30 minutes

- Initial dry time: ~2 hours

- Full cure time: 24–72 hours (varies by temperature)

- Slower cure in cold conditions without accelerator

⚠️ Pollution & Surface Effects

Flex Marble Sheet Glue:

- Can retain oil, potentially causing stains or discoloration on natural stone surfaces

- Best suited for small-scale repairs and quick bonding tasks

Epoxy Dry-Hanging Glue:

- No oil seepage

- Clean application with stable bonding and minimal surface impact

📉 Usage Limitations & Best Applications

Flex Marble Sheet Glue:

Not recommended for large-area adhesion or structural applications

Water resistance and durability are lower than epoxy-based adhesives

Can shrink during curing, which may affect bonding over time

Best used for:

- Quick repairs

- Stone patching

- Temporary installations

Epoxy Stone Dry-Hanging Glue:

- Ideal for structural bonding

- Handles thermal expansion, outdoor exposure, and long-term durability

- Used in facades, cladding, and heavy-duty applications

🛠 Product Benefits

- Flexible, lightweight design perfect for curved surfaces and creative layouts

- Quick installation with fast-curing glue options

- Minimal structural load – ideal for renovation projects

- Natural stone finish without the bulk of traditional slabs

- Compatible with various surfaces: concrete, plywood, drywall, and more

Upgrade your project with the versatility of Flex Marble Sheets – the modern solution for decorative stone finishes without the weight or complexity.

Share