1

/

of

16

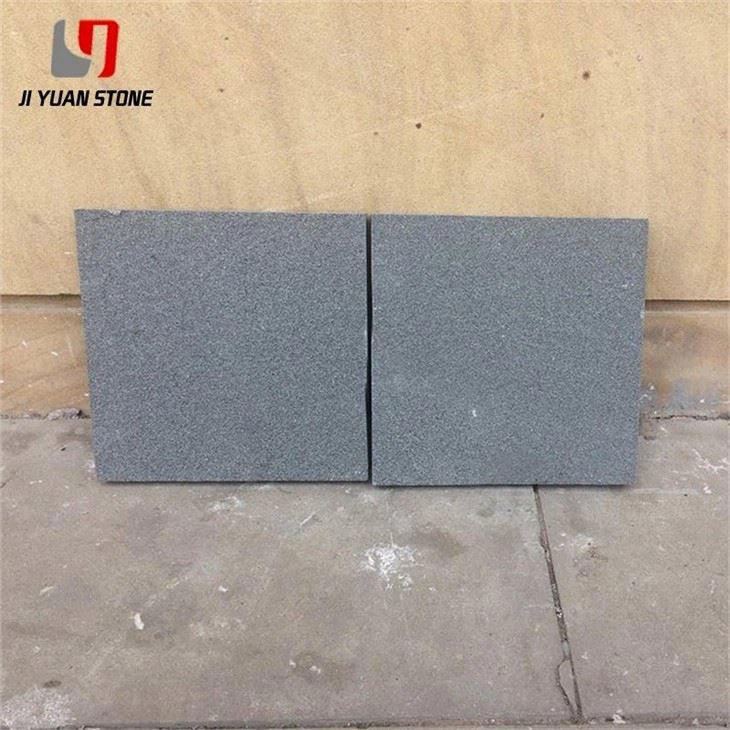

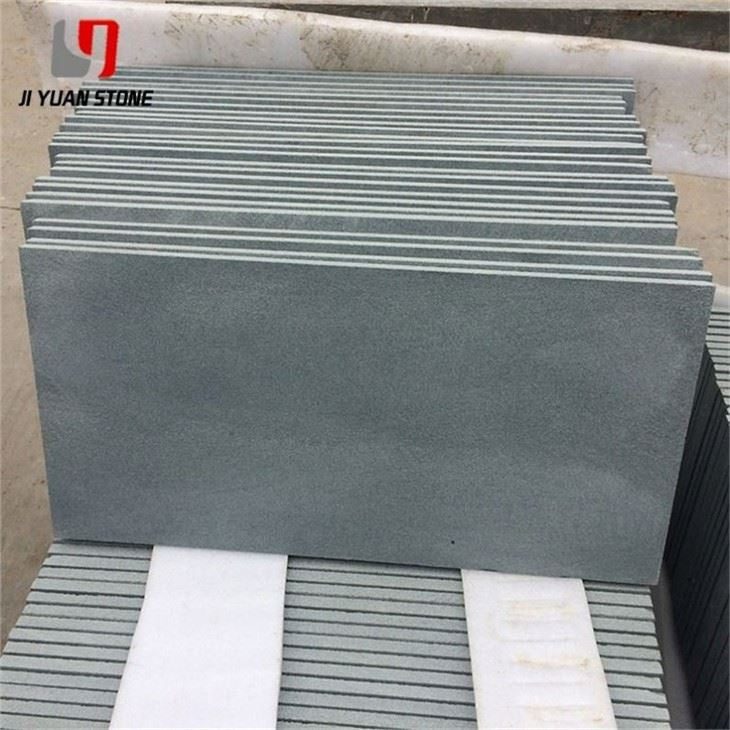

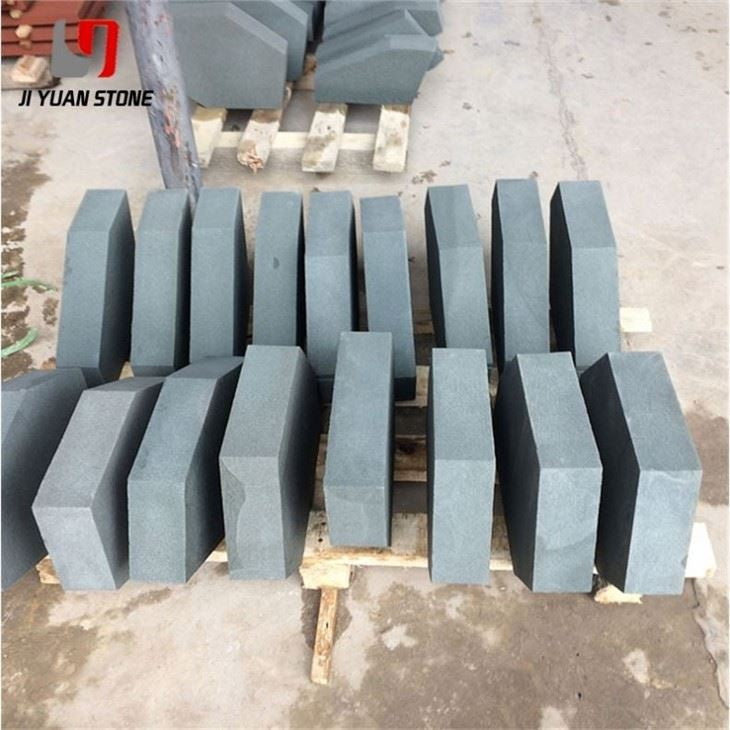

Flamed Gray Sandstone

Flamed Gray Sandstone

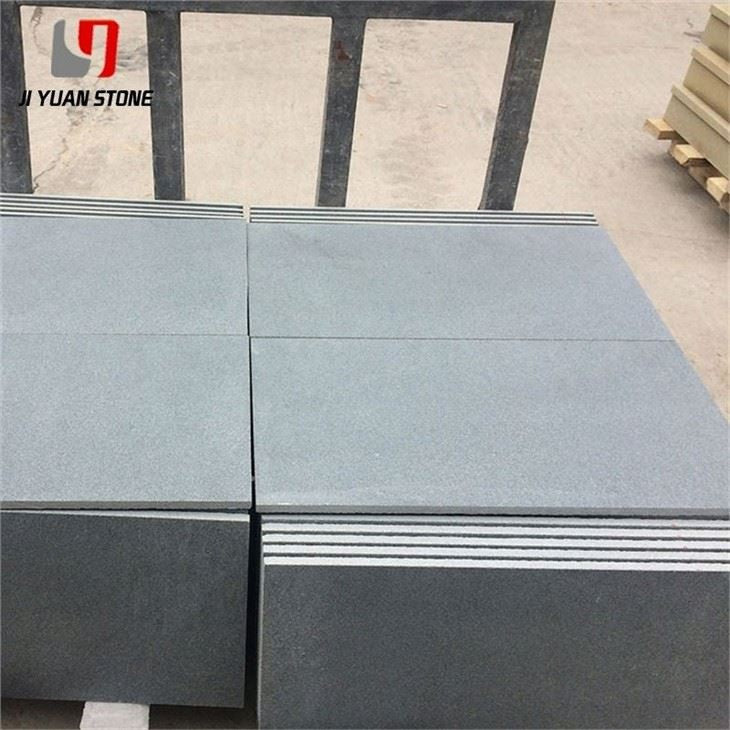

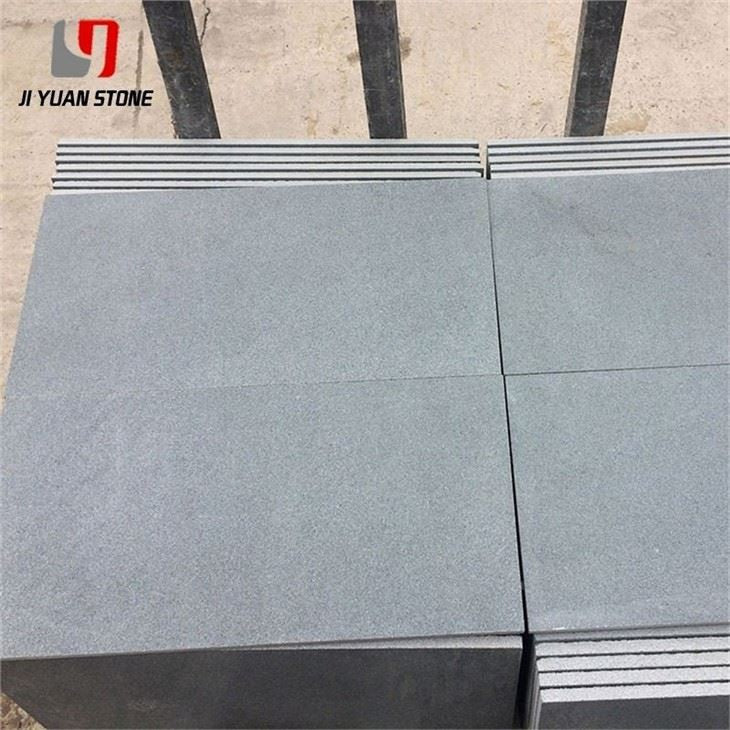

Experience the durability and unique look of our Flamed Gray Sandstone. With its natural flamed texture and gray color, this stone is perfect for both indoor and outdoor use. Its heat-resistant properties make it ideal for high traffic areas and its natural slip resistance guarantees safety. Upgrade your space with Flamed Gray Sandstone today.

| Feature | Details |

|---|---|

| Material | Natural Sandstone |

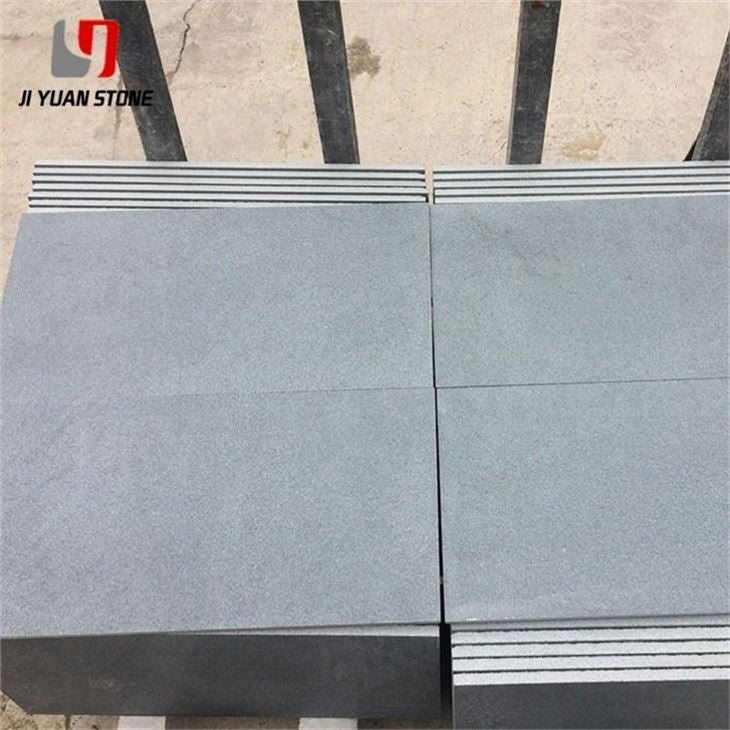

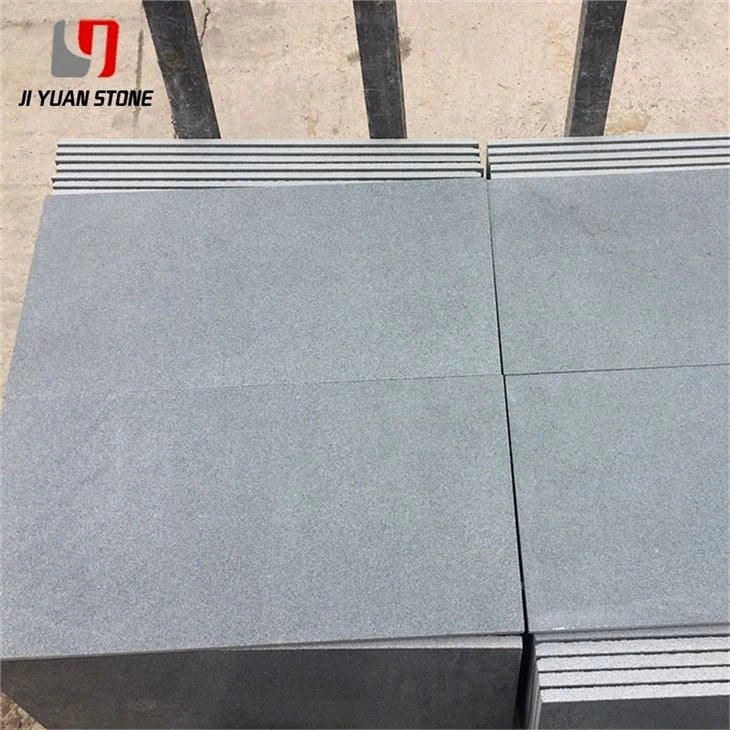

| Surface Finished | Honed,Flamed,Bush-hammered,Brushed,Nature,Mushroom,Sawn etc |

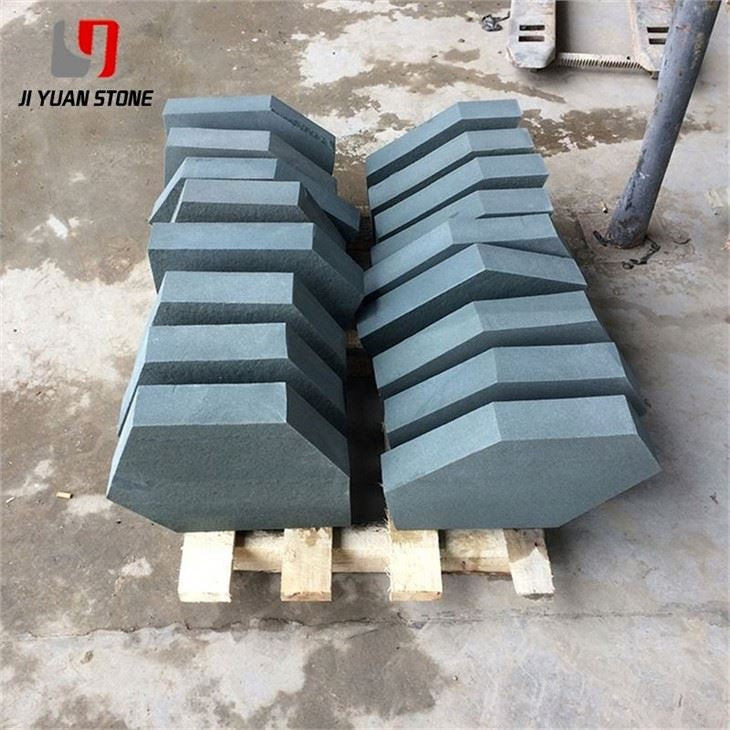

| Finished Products | Floor tiles, Wall cladding, Countertops, Windowsills, Special-shaped tiles, Small slabs, Swimming pool, steps, wall panel, flooring, veneers, slabs, coping tiles, etc |

| Color | Yellow,black,white,red,purple wood,green,grey,rainbow etc |

| Finished | Honed, Split, Sandblasted, Sawn, Antiqued, Pineapple, etc. |

| Dimension |

|

| Usage | Interior & Exterior Decoration |

| Quality Control |

Thickness Tolerance:+/-0.5mm,+/-1mm; All Products Checked by Experienced QC |

| MOQ | Welcome Small Trail Orders |

| Size | Customized Pls contact us for the newest catalog of sandstone,marble,granite,quartz,mosaic,limestone,travertine etc |

| Sample | Contact Us For Free Samples |

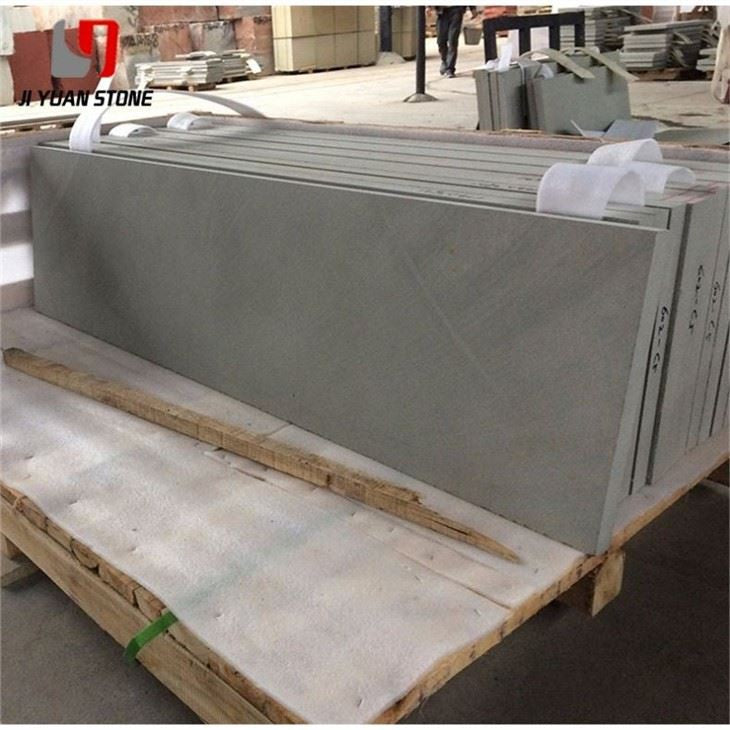

| Package | Standard Exporting Seaworthy Package ( Inner: Plastic Film and Foam; Outer: strong seaworthy wood Crates or Pallets.)Payment |

| Payment | T/T, L/C, Escrow, Western Union |

| Delivery | Within 2 Weeks After Deposit |

Key Considerations for Ordering Flamed Gray Sandstone

- Source Selection & Ore Reserves

- It is best to find the original ore and understand the reserves of the ore source.

- Stone blocks should come from the same pit or the same level to ensure consistency in color and texture.

- Inspection & Selection of Materials

- Before ordering the flamed gray sandstone, a special person must visit the stone factory to inspect the slab, ensuring the correct color and quantity.

- Manufacturer Selection & Processing Standards

- Choosing a Processing Manufacturer:

- Finished products from the same section or different but related and spliced parts should be processed by the same manufacturer.

- The same material should be processed by the same manufacturer.

- Special-shaped products and plates within the same section should be processed by the same manufacturer.

- Effective Communication with Manufacturers

- Production and Quality Control:

- Define product processing quality standards, including appearance, dimensional deviation, gloss, etc.

- Clarify color, style, and pattern requirements: samples should be designed and confirmed by Party A, the stone manufacturer, and the project department (sample size should be at least 300×300mm, preferably 1m×1m).

- Ensure quality priority for key positions in the project.

-

Production & Logistics Planning:

4. Specify product delivery period and processing sequence with a clear production plan.

5. Specify exact processing positions and quantities, reflected in the production plan.

6. Define methods for picking up goods and the exact unloading location. -

Contractual Agreements:

7. Agree on processing loss rates, back rib and back plate methods, protective measures, edge grinding, chamfering processes, polishing gloss, openings, and packaging methods.

8. Clarify responsibilities and compensation standards of both parties.

Share