Fexilbe Stacked Stone Veneer

Fexilbe Stacked Stone Veneer

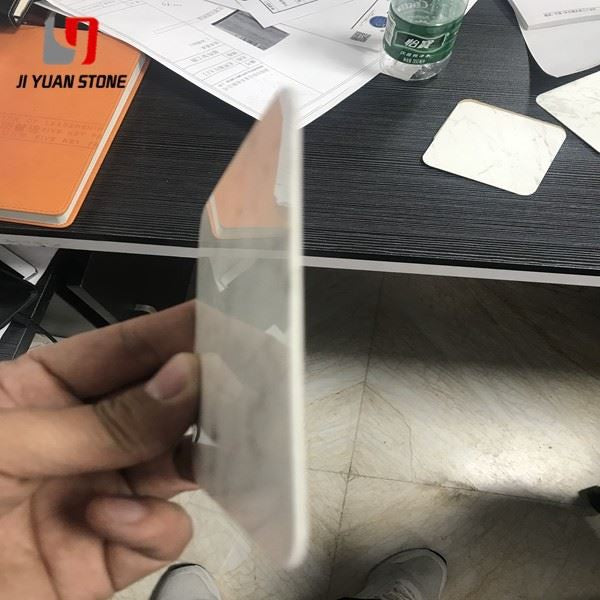

Flexible Stacked Stone Veneer – Lightweight Elegance for Modern Spaces

Explore the versatility of Fexilbe Stacked Stone Veneer. With its flexible design, it can be installed on curved surfaces, adding a touch of elegance to any space. Its natural stone appearance provides a timeless and durable option for your home or business. Upgrade your design with Fexilbe Stacked Stone Veneer.

| Feature | Details |

|---|---|

| Product | fexilbe stacked stone veneer |

| Finished Products | Floor tiles, Wall cladding etc |

| Colour | Many colors available |

| Stone Type | Average weight: 1-2mm thickness, average weight 2kgs per sqm Stone Surface Finish: Polished, Honed and Brushed. |

| Backing | Fibreglass |

| Thickness | 1-5mm, or Customized |

| Biggest Size | 1-2mm size 1200*600mm 3-5mm size 2440*1220mm 3-5mm biggest size for some slate material 3050*1220mm |

| Average Weight | 1-2mm thickness, average weight 2kgs per sqm |

| Stone Surface Finishes | Polished, Honed and Brushed |

| Cutting Machine | Tool scissors, Portable marble cutting machine, Portable angle grinder, Infrared bridge cutting machine, Table saw |

| Installation Instructions |

1. Measure size-paste textured paper-draw lines 2. Stone cutting and edge grinding (1. Tool scissors for cutting, 2. Hand-held marble cutting machine.) 3. If there is a need to dig holes, use a hand-held electric drill to punch around first and then use a hand-held angle grinder to cut. 4. Stone gluing (even grid-like gluing, at least 1 cm away from the edge of the stone to prevent glue overflowed) 5. DIY collage according to your own preference ( Can leave 2-3mm gap sealant treatment. Also can be combined with aluminum alloy transition strips, edge strips, and external corner strips. ) |

Transform your interiors or exteriors with our Flexible Stacked Stone Veneer, designed for effortless installation, structural integrity, and timeless style. Whether for residential or commercial use, this modern wall cladding solution combines durability with aesthetic appeal, offering an easy-to-handle alternative to traditional stone.

🔍 Materials Analysis

Our flexible stacked stone veneer system is engineered with premium materials and specialized accessories to ensure strength, flexibility, and long-term performance:

- Dry-Hanging System: Utilizes special dry-hanging accessories for secure installation. Select the designated stone, fix the frame, and install using our specialized AB glue for stone applications.

- Impact Protection: Features a 5×5 mm anti-collision angle and six-sided stone protection during installation.

- Surface Finish: Seamless joints are achieved with high-grade caulk. A protective film is applied to preserve the finish from construction-related wear.

- Support Structure: Incorporates square tubes or galvanized angle iron with a cement pressure plate for a solid base. Includes fireproof and moisture-resistant components.

🛠 Detailed Construction Process

Every project benefits from our proven, step-by-step approach that ensures structural reliability and clean finish:

Process 1:

Preparation work → Site lay-out → Material processing → Base treatment → Stone dry-hanging frame fixation → Special AB glue application → Stone paving → Final surface treatment

Process 2:

Preparation work → Site lay-out → Partition wall structure → Cement pressure/fireproof board sealing → Stainless steel customization → Stone paving → Stainless steel installation → Final finishing

🔧 Stone & Stainless Steel Connection Tips

For seamless integration between stainless steel and stone, follow these key guidelines:

- Maintain proper alignment between the splicing heights.

- Leave adequate process seams and consider edge pressing.

- Ensure stainless steel thickness and wood base are ~3mm.

- Use glass glue and universal glue for flat plate adhesion.

- Keep protective films in place during construction for finish safety.

📦 Technical Highlights

- Frame Materials: Channel steel, galvanized angle iron, and wood keels.

- Protective Layers: Six-sided stone protection, special caulk for clean seams, and surface protection film.

- Custom Elements: Stainless steel detailing for a professional, high-end appearance.

- Versatile Application: Ideal for both indoor and outdoor walls, commercial or residential settings.

Add contemporary sophistication to your next project with our Flexible Stacked Stone Veneer – where beauty meets durability.

👉 Shop Now

Share