Engineered Quartz Stone Slab

Engineered Quartz Stone Slab

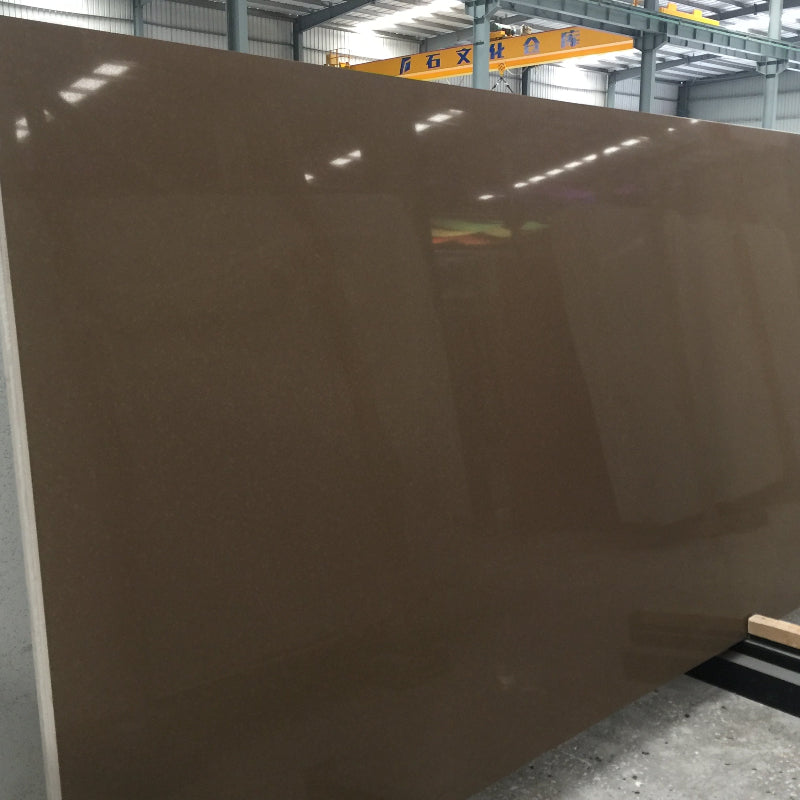

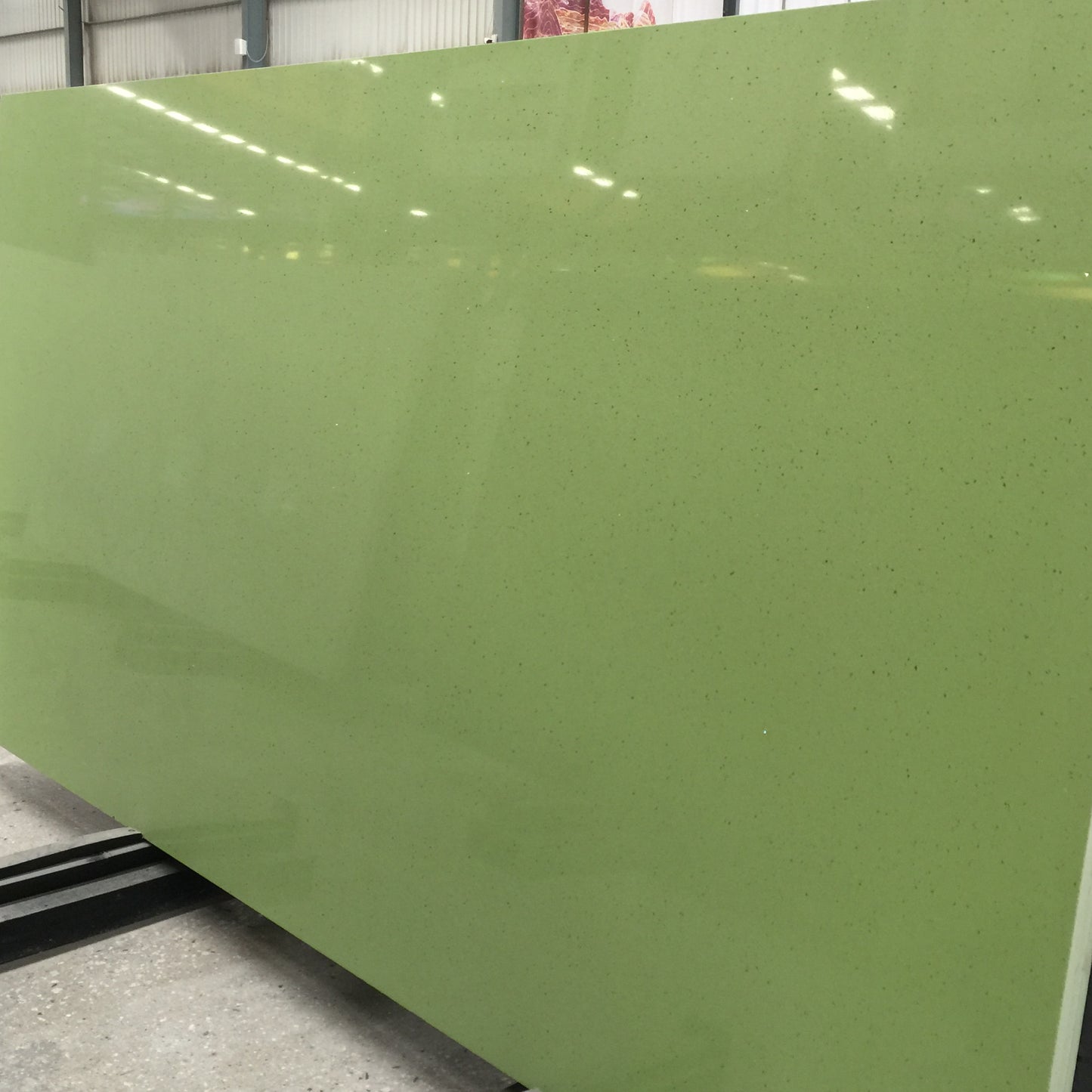

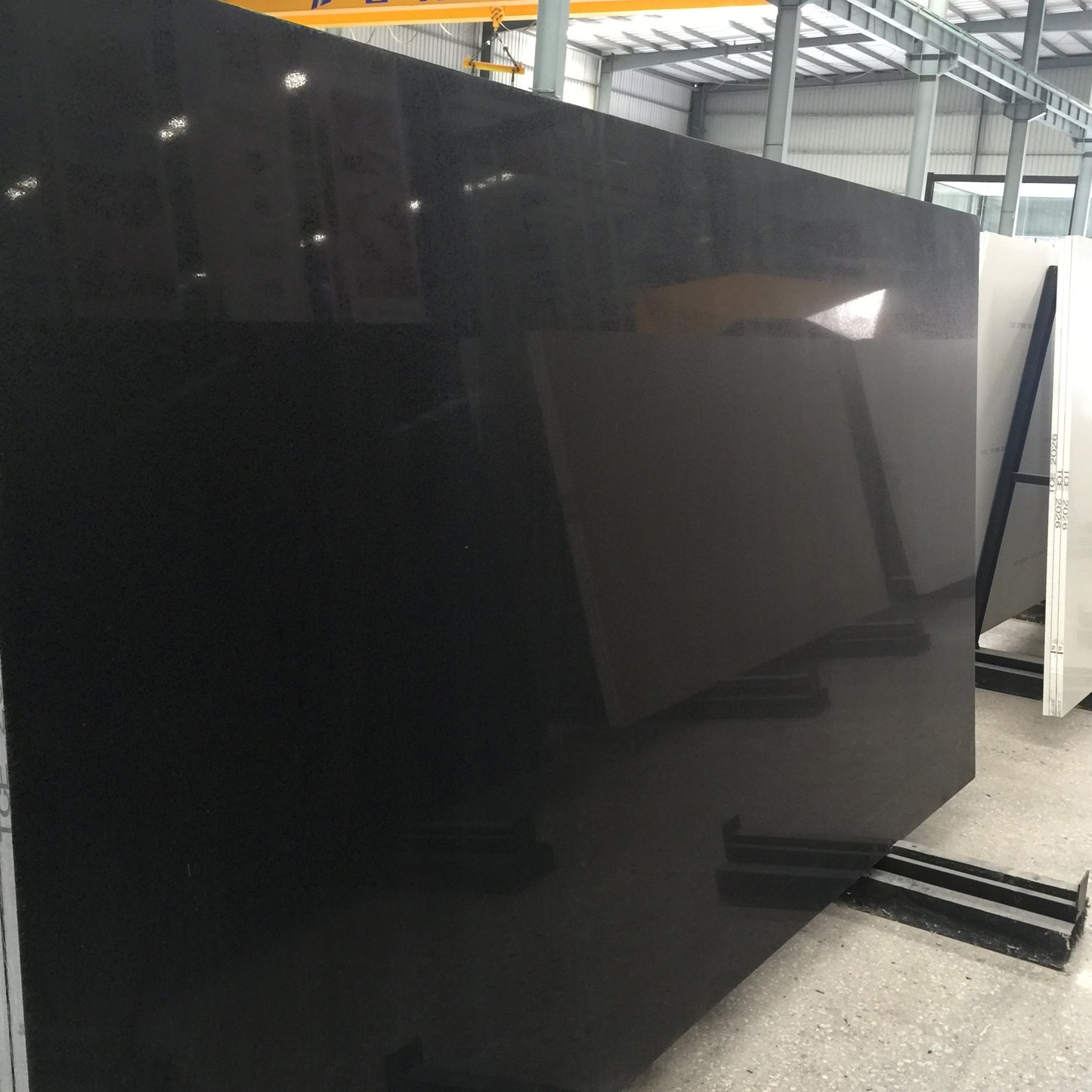

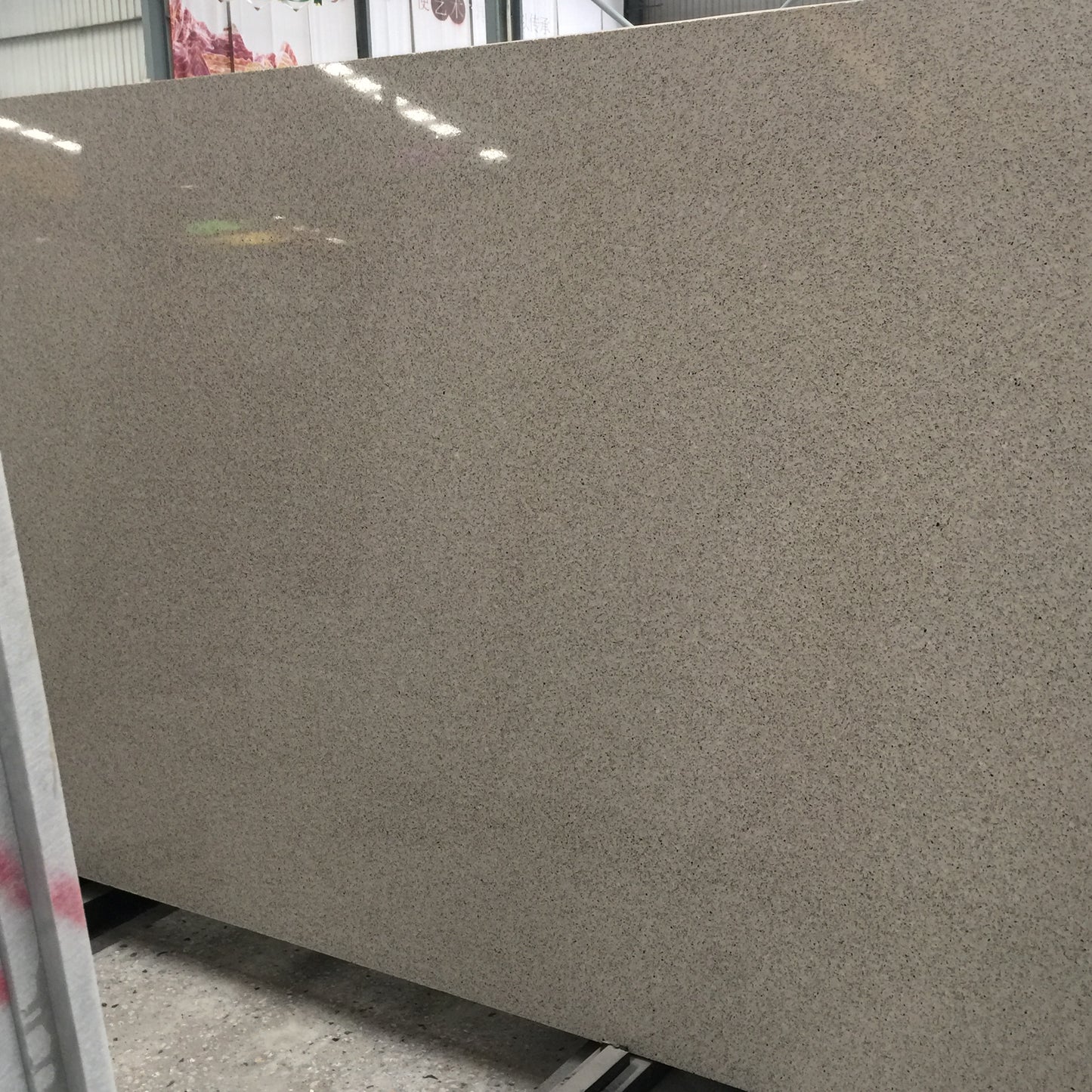

Engineered Quartz Stone Slab – A Strong, Stylish & Sustainable Choice

Discover the ideal blend of form and function with our Engineered Quartz Stone Slab. With its durable, low-maintenance composition, this slab is perfect for enhancing the look and functionality of any space. Made with precision engineering, it offers the perfect balance of beauty and practicality. Experience the modern convenience and elegance of our Engineered Quartz Stone Slab today.

| Feature | Details |

|---|---|

| Product | Engineered Quartz Stone Slab |

| White engineered quartz stone kitchen countertop Size: | 96"x26", 108''x26''; |

| Island size |

72"x36",78"x36",83"x42",98"x39". Width for back splashes:2'',4'',6'', according to your requirement; |

| Vanity top Size |

|

| Big Slab Size |

|

| Raw Material | 93% Natural Quartz Powder +7% Resin |

| Slab Size | 3200*1600mm/2800*1400/Customized Size |

| Thickness | 18mm/20mm/30mm |

| Finished | Polished |

| Technical Data | Density:2.36~2.40 g/cm³ |

| Water Absorption | 0.01~0.02 % |

| Mohs' Hardness | 6~7 Mohs |

| Resistance to Deep Abrasion | 5×10-2 g/cm² |

| Resistance to Acids | YES |

| Resistance to Alkalis | YES |

| Advantage | Non-porus |

| Slabs Packing |

1) All surface covered by PET film 2) With polished face to face and surrounded by foam105 slabs of 20mm per 20ft container70 slabs of 30mm per 20ft container |

| Application |

Home application:Countertop, Vanity top, Wall, Table, etc.Commercial application:Reception counter, Windowsill, work counter for the fast food, table for the bar, floor, steps etc. |

Engineered quartz stone slab is a modern artificial stone material renowned for its exceptional durability, uniform texture, and refined aesthetics. Manufactured using over 90% natural quartz crystals, blended with high-performance resins and pigments, this engineered surface offers a wide array of colors and styles – from solid and patterned slabs to gemstone-inspired designs.

Thanks to its high density, color consistency, and resistance to daily wear, engineered quartz slabs have become the go-to alternative to natural marble for homeowners and designers seeking beauty, performance, and eco-consciousness.

💡 Why Choose Engineered Quartz Stone Slabs?

✅ Extremely Durable & Non-Porous Surface

✅ Consistent Color & Texture Across the Slab

✅ High-Temperature Resistance

✅ Stain & Scratch Resistance

✅ Low Maintenance & Long Life Span

✅ Eco-Friendly & Cost-Effective

⚠️ What Are the Precautions for Using Engineered Quartz Stone Slab?

While engineered quartz slabs are built to last, certain precautions help ensure their maximum performance and lifespan:

1 . Handle with Care

Quartz glass-based slabs are valuable materials—handle gently to avoid chipping or cracking.

2 . Respect Maximum Temperature Limits

Each quartz slab has a maximum operating temperature. Do not exceed it, or the slab may crystallize or deform.

3 . Clean Thoroughly Before High-Temperature Use

Before exposing to heat, clean using 10% hydrofluoric acid or alcohol. Use high-purity water for rinsing. Always wear thin-line gloves and avoid direct contact with the surface.

4 . Prefer Continuous Over Intermittent High-Temperature Use

Sustained use at high temperatures extends the slab’s life, while frequent heating and cooling shortens it.

5 . Beware of Residual Strain & Shape-Induced Stress

Quartz has excellent thermal stability, but strain and shape can impact performance. Avoid rapid or extreme temperature changes.

6 . Avoid Alkaline Exposure at High Temps

Quartz is acidic by nature—contact with alkaline substances like water glass, potassium compounds, or asbestos at high temps reduces anti-crystallization strength.

🏡 Versatile Applications & Market Trends

Engineered quartz slabs are suitable for:

- Kitchen Countertops

- Bathroom Vanities

- Wall Cladding & Flooring

- Dining Tables

- Commercial Surfaces

With a wide range of particle sizes and design series—solid colors, multi-color patterns, gemstone styles—these slabs meet both aesthetic and practical demands. Their high utilization rate, low maintenance, and environmentally conscious manufacturing have made them an increasingly popular alternative to marble, especially as natural stone resources become limited.

Whether you're designing a contemporary kitchen, a luxurious bathroom, or a commercial workspace, engineered quartz stone slabs deliver unmatched durability, beauty, and value.

✨ Choose engineered quartz for timeless elegance, superior functionality, and sustainable living.

Share